LCP composite film suitable for high frequency and high speed and preparation method thereof

A composite film, high-speed technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of poor structural characteristics, high-frequency transmission loss, large hygroscopicity, etc., to improve the strength and modulus , excellent insulation performance, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

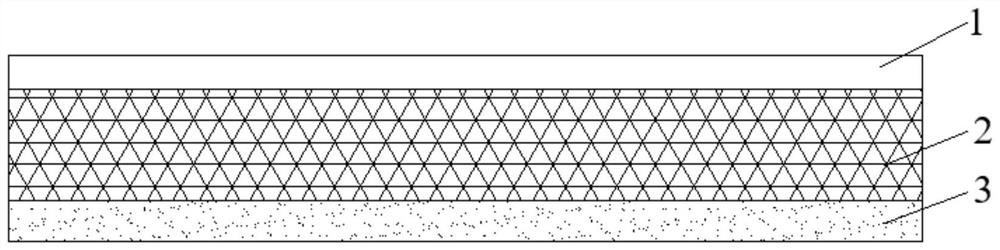

[0018] Specific implementation mode one: combine figure 1 , the present embodiment is an LCP composite film suitable for high frequency and high speed, characterized in that the LCP composite film suitable for high frequency and high speed includes TLCP layer (1), TLCP-plastic composite layer (2) and base (3);

[0019] The TLCP layer (1) contains TLCP and polytetrafluoroethylene, and the mass fraction of polytetrafluoroethylene is 15-30%, and the balance is TLCP;

[0020] The TLCP-plastic composite layer (2) contains TLCP fiber, PET and polytetrafluoroethylene, and the mass fraction of TLCP fiber is 10-20%, the mass fraction of PET is 20-30%, and the balance is polytetrafluoroethylene vinyl.

[0021] The tensile strength of the TLCP fiber in this embodiment exceeds 18cN / dtex, and the tensile strength of plastic products can be greatly improved by using the TLCP fiber as a skeleton.

[0022] In this embodiment, PET is polyethylene terephthalate, which has good electrical ins...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 , the difference between this embodiment and the specific embodiment one is: the TLCP fiber is one or two layers in the TLCP-plastic composite layer (2); when the TLCP fiber is one layer, the TLCP-plastic composite layer (2) The mass fraction of TLCP fibers in the middle is 10-15%, and the TLCP fibers are arranged longitudinally; when the TLCP fibers are two layers, the mass fraction of TLCP fibers in the TLCP-plastic composite layer (2) is 15-20%, and the same layer The TLCP fibers are arranged in the same direction, and the TLCP fibers in two adjacent layers are arranged in a cross. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 The difference between this embodiment and the first or second embodiment is that the TLCP is a copolyester of p-hydroxybenzoic acid and 2-hydroxy-6-naphthoic acid. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com