Nano hybrid P(VDF-TrFE)(polyvinylidene fluoride copolymer) composite film as well as preparation method and application thereof

A technology of polyvinylidene fluoride and copolymer, which is applied in the field of nano-hybrid polyvinylidene fluoride copolymer composite film and its preparation and application, can solve the problems that polyvinylidene fluoride is easily corroded by atomic oxygen, etc., and achieve performance improvement, Good compatibility and high modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

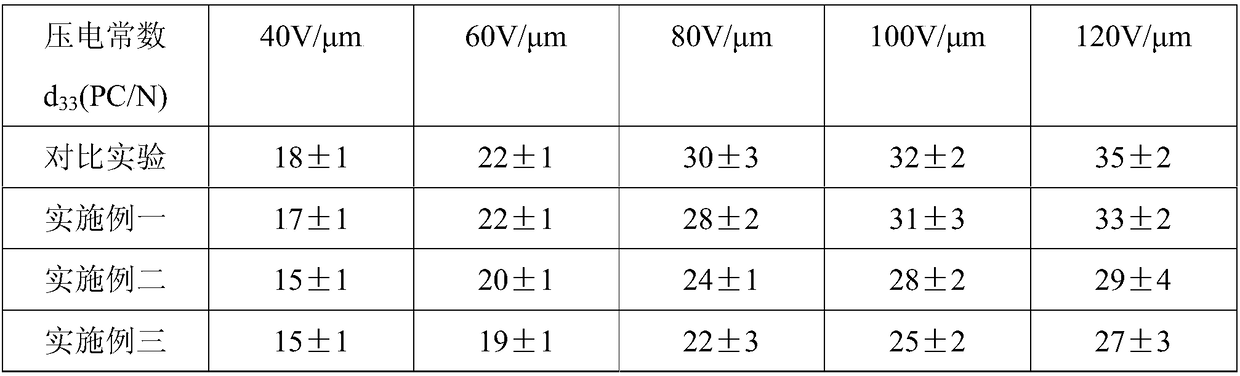

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: In this embodiment, a nano-hybrid polyvinylidene fluoride copolymer composite film contains 92% to 98% of polyvinylidene fluoride copolymer P (VDF-TrFE) in terms of mass percent Siloxane 2-8%.

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the nano-hybrid polyvinylidene fluoride copolymer composite membrane contains polyvinylidene fluoride copolymer P(VDF-TrFE) 95-97% by mass percentage %, polyhedral oligomeric silsesquioxane 3-5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the polyhedral oligomeric silsesquioxane is a polyhedral oligomeric silsesquioxane whose functional group is fluorinated propyl. Others are the same as in the first or second embodiment.

[0029] Polyhedral oligomeric silsesquioxane POSS is a class of structural formula (RSiO 1.5 ) n The cage structure, the structural formula is:

[0030] where R is - CF 3 , n=8, 10, 12..., the molecule is based on the inorganic structure Si-O-Si as the core, and the organic functional group is connected to the Si atom, which can chemically react with the resin monomer and become a part of the polymer main chain. POSS is The real chemical nanostructure has a molecular size of about 1.5nm.

[0031] POSS also has a variety of POSS along with the difference of the R group that connects the cage type silicon oxygen, what is used in the present invention is that the R group is fluorinated propyl group (flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com