Bridge expansion joint with variable-rigidity clamping end

A clamping end and expansion joint technology, applied in the field of expansion joints, can solve problems such as troublesome replacement, difficult maintenance and replacement, weak clamping and failure of the clamping end, etc., and achieves the effect of high strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

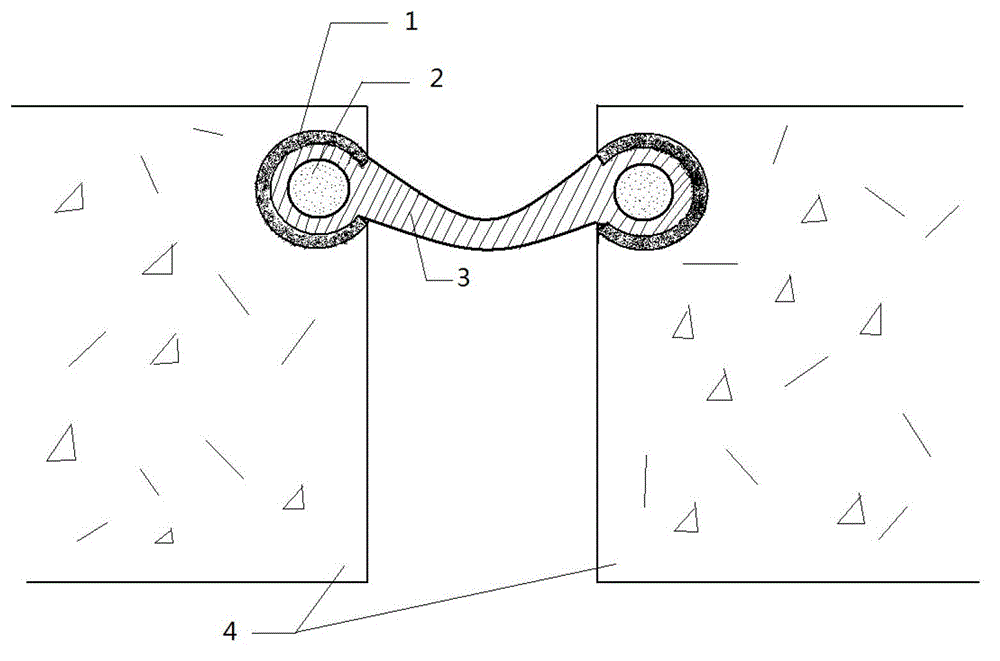

[0016] see figure 1 , which shows a bridge expansion joint with a variable stiffness clamping end according to a preferred embodiment of the present invention, the expansion joint includes a body 3, a variable stiffness clamping end and a fixed edge beam 1, the body 3 and a variable stiffness clamping end Connected into one body, the fixed side beam 1 is embedded in the bridge beam end 4 and forms a receiving groove, the clamping end is embedded in the receiving groove, and the clamping end includes a cavity 2 and a connection with the cavity 2 A sealable opening (not shown in the figures) is used for filling the cavity 2 with a hardenable filling material in a fluid state.

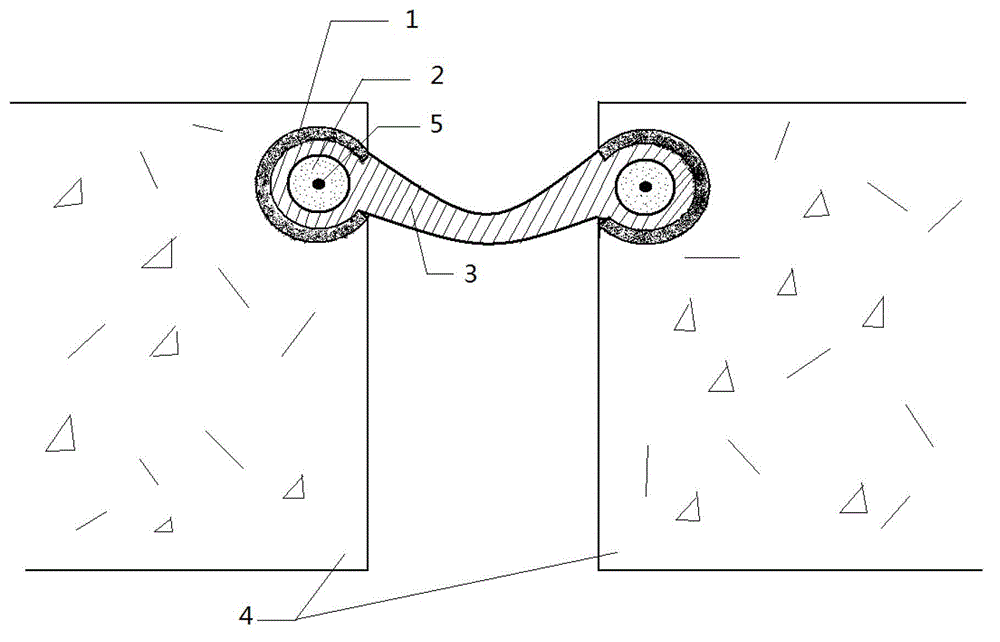

[0017] Preferably, the filling material is resin. Preferably, the resin is gas, liquid or solid powder. Preferably, see figure 2 , the cavity 2 is provided with a heating wire 5, it can be understood that the filling material can also use other ways to change the stiffness. Preferably, the filling ma...

Embodiment 2

[0020] The expansion joint includes a rubber strip body 3 , a clamping end with variable stiffness, a fixed side beam 1 and an anchoring device (not shown in the figure). Wherein the anchoring device is used for anchoring and fixing the side beam 1 .

[0021] as attached figure 2 , the fixed side beam 1 adopts a metal side beam. The expansion joint body 3 adopts a rubber waterstop. The clamping end is a cavity structure, and the heating wire 5 is placed in it in advance. The cavity at the clamping end is filled with variable stiffness material. The variable stiffness material can be resin.

[0022] Installation process

[0023] Before installation, anchor and fix the side beam 1. The heating wire 5 is put into the cavity 2 at the clamping end of the expansion joint. Flatten the clamping end of the expansion joint and embed it in the receiving groove of the side beam 1. Use a plunger pump to inject resin into the cavity 2 at the clamping end of the expansion joint 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com