A kind of high-strength high-plasticity steel making and production method thereof

A production method and high plasticity technology, applied in the direction of improving process efficiency, can solve the problems of increased energy consumption, reduced production efficiency, and no mixing of scrap recycled steel, etc., to improve strength and plasticity, improve production efficiency, and improve environmental protection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

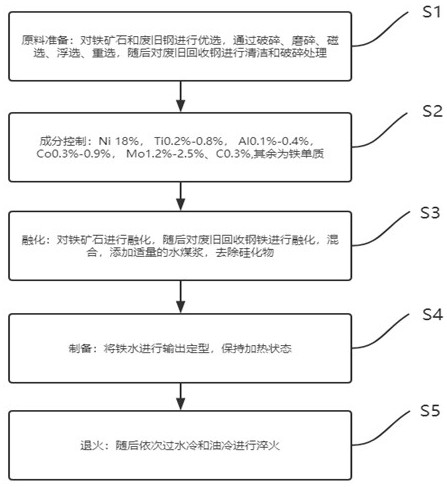

selection, followed by cleaning and shredding of scrap recycled steel;

Step 2: composition control, Ni 18%, Ti0.2%-0.8%, Al0.1%-0.4%, Co0.3%-0.9%,

Mo1.2%-2.5%, C0.3%, the rest is iron element;

Step 3: melting, iron ore is melted, then waste and old recycled steel is melted, mixed, and an appropriate amount is added

coal water slurry to remove silicide;

Step 4: preparation, the molten iron is output and shaped, keeps heating state;

[0028] Step 5: annealing, followed by water cooling and oil cooling followed by quenching.

Concrete, according to the operation steps in the step 1, iron ore selects magnetite (Fe O ), hematite (Fe O ) and

Siderite (FeCO3), the outer wall of scrap steel to remove oxide layer, the size of scrap steel is less than 10 cm.

Concretely, according to the operation steps in step 1, scrap recycling steel adopts polishing machine to clean, and polishing machine adopts

1000 grit sandpaper.

Concrete, according to the operation steps in step 2, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com