Vanadium-doped zirconium titanate photocatalytic material as well as preparation method and application thereof

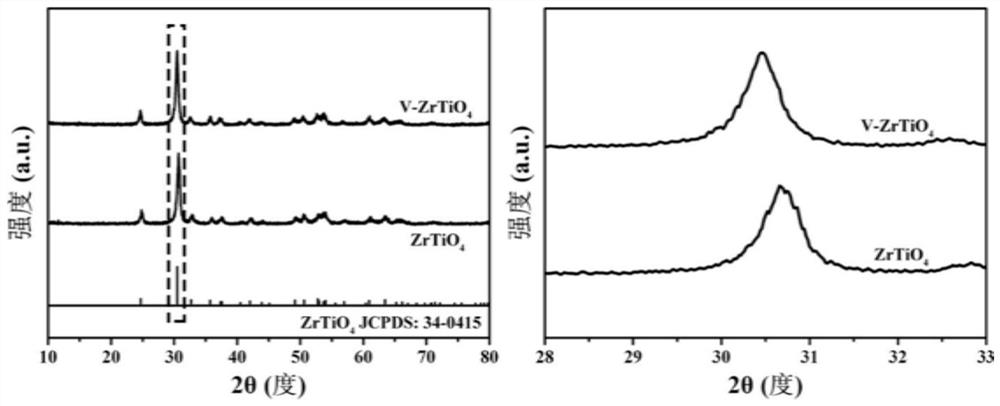

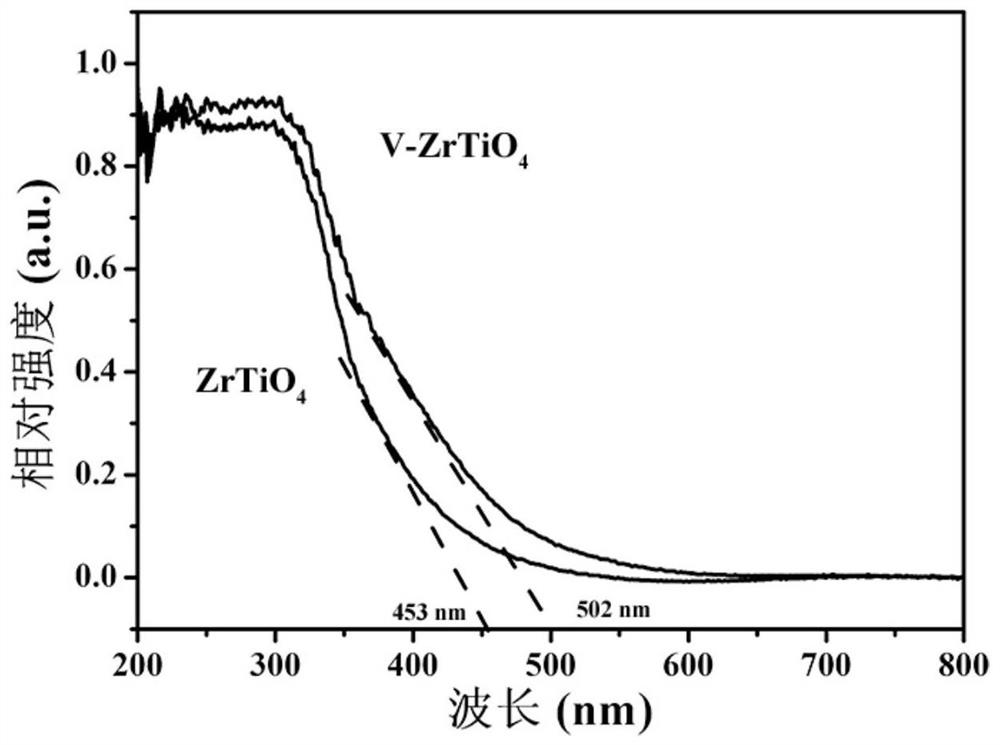

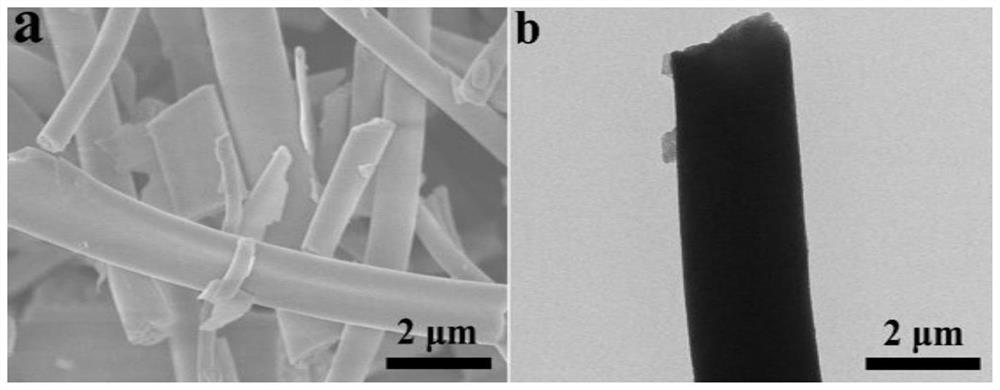

A photocatalytic material, zirconium titanate technology, applied in the field of photocatalytic materials, can solve the problems of cost barriers and high scarcity of precious metal materials, and achieve the effect of improved absorption intensity, good cycle stability, smoothness and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a vanadium-doped zirconium titanate photocatalytic material, comprising the following steps:

[0048] (1) 1.2g zirconium oxychloride octahydrate, 1.27g tetrabutyl titanate and 1.0g citric acid were dissolved in 12mL methanol, and then 0.6mL mass concentration was added dropwise to be 37wt% hydrochloric acid solution to adjust the mixing system The pH value is 3.0, finally add 0.013g of ammonium metavanadate, stir for 60min, and obtain the precursor solution;

[0049] (2) Add 0.8g of polyvinylpyrrolidone (PVP) to the precursor solution prepared in step (1), stir until forming a homogeneously mixed precursor sol; %, electrospinning was carried out at room temperature, the spinning receiving distance was 20 cm, and the advancing speed was 1 mL / h to obtain precursor fibers.

[0050] (3) Dry the precursor fiber prepared in step (2) at 40°C for 16h, then place it in a muffle furnace, raise the temperature to 700°C at a heating rate of 2°C / min, and keep...

Embodiment 2

[0055] A method for preparing a vanadium-doped zirconium titanate photocatalytic material, comprising the following steps:

[0056] (1) 1.1g zirconium oxychloride octahydrate, 1.16g tetrabutyl titanate and 0.8g citric acid are dissolved in the methanol of 15mL, then dropwise add 0.8mL mass concentration to be 99wt% acetic acid, adjust the mixing system The pH value is 4.0, finally add 0.03g of sodium vanadate, and stir for 40min to obtain the precursor solution;

[0057] (2) Add 1.2g of polyvinylpyrrolidone (PVP) to the precursor solution prepared in step (1), and stir until forming a homogeneously mixed precursor sol; %, electrospinning was carried out at room temperature, the spinning receiving distance was 20 cm, and the advancing speed was 1.2 mL / h to obtain precursor fibers.

[0058] (3) Dry the precursor fiber prepared in step (2) at 60°C for 12h, then place it in a muffle furnace, raise the temperature to 800°C at a rate of 2°C / min, and keep it at 800°C for 200min to o...

Embodiment 3

[0060] A method for preparing a vanadium-doped zirconium titanate photocatalytic material, comprising the following steps:

[0061] (1) 1.4g zirconium oxychloride octahydrate, 1.48g tetrabutyl titanate and 1.3g citric acid were dissolved in 14mL methanol, and then 0.8mL mass concentration was added dropwise to be 37wt% hydrochloric acid solution to adjust the mixing system The pH value is 2.0, finally add 0.013g ammonium metavanadate, stir for 60min, and obtain the precursor solution;

[0062] (2) Add 1.4g polyvinylpyrrolidone (PVP) to the precursor solution prepared in step (1), stir until forming a homogeneously mixed precursor sol; the gained precursor sol is 20kV in pressure, and the relative humidity is 30% , electrospinning was carried out at room temperature, the spinning receiving distance was 15 cm, and the advancing speed was 0.8 mL / h, to obtain precursor fibers.

[0063] (3) Dry the precursor fiber prepared in step (2) at 50°C for 14h, then place it in a muffle fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com