Polyisocyanate adhesive, and production method and production device thereof

A technology of polyisocyanate glue and production equipment, which is applied in the direction of mixing methods, chemical instruments and methods, polyurea/polyurethane adhesives, etc., and can solve problems such as low tensile strength, heavy odor, and short elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Such as figure 1 As shown, a polyisocyanate glue is composed of the following parts by weight: 10 parts of polyphenyl polymethylene polyisocyanate, 277 parts of diisocyanate, 12 parts of hexamethylene diisocyanate, 6.5 parts of terpene resin Parts, 22 parts of ethyl acetate, 23 parts of methyl acetate and 11.5 parts of propylene glycol methyl ether acetate.

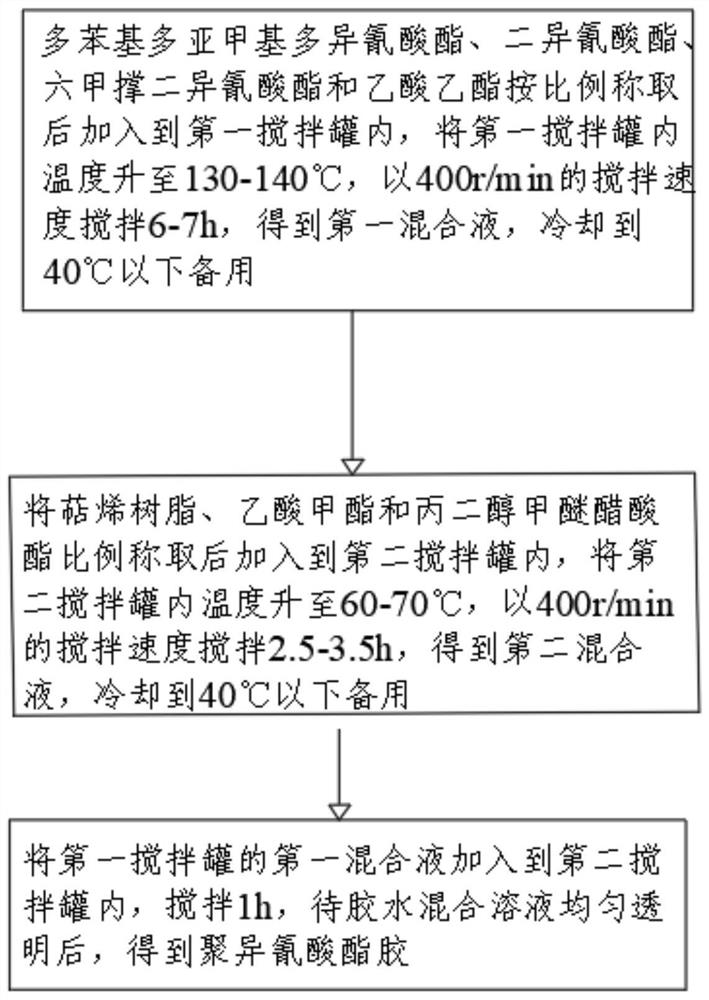

[0042] A kind of production method of polyisocyanate glue, production method step is as follows:

[0043] Step 1, polyphenyl polymethylene polyisocyanate, diisocyanate, hexamethylene diisocyanate and ethyl acetate are weighed in proportion and added to the first stirring tank, and the temperature in the first stirring tank is raised to 140 °C to Stir at a stirring speed of 400r / min for 7h to obtain the first mixed solution, and cool it to below 40°C for later use;

[0044] Step 2. Weigh the proportions of terpene resin, methyl acetate and propylene glycol methyl ether acetate and add them to the second stirring t...

Embodiment 2

[0047] A polyisocyanate glue, the polyisocyanate glue is composed of the following components in parts by weight: 8 parts of polyphenyl polymethylene polyisocyanate, 30 parts of diisocyanate, 15 parts of hexamethylene diisocyanate, 8.5 parts of terpene resin, acetic acid 25 parts of ethyl ester, 20 parts of methyl acetate and 13.5 parts of propylene glycol methyl ether acetate.

[0048] A kind of production method of polyisocyanate glue, production method step is as follows:

[0049] Step 1, polyphenyl polymethylene polyisocyanate, diisocyanate, hexamethylene diisocyanate and ethyl acetate are weighed in proportion and added to the first stirring tank, and the temperature in the first stirring tank is raised to 130 °C to Stir at a stirring speed of 400r / min for 6h to obtain the first mixed solution, and cool to below 40°C for later use;

[0050] Step 2. Weigh the proportions of terpene resin, methyl acetate and propylene glycol methyl ether acetate and add them to the second ...

Embodiment 3

[0053] A polyisocyanate glue, the polyisocyanate glue is composed of the following components in parts by weight: 12 parts of polyphenyl polymethylene polyisocyanate, 33 parts of diisocyanate, 18 parts of hexamethylene diisocyanate, 7.5 parts of terpene resin, acetic acid 28 parts of ethyl ester, 25 parts of methyl acetate and 15.5 parts of propylene glycol methyl ether acetate.

[0054] A kind of production method of polyisocyanate glue, production method step is as follows:

[0055] Step 1, polyphenyl polymethylene polyisocyanate, diisocyanate, hexamethylene diisocyanate and ethyl acetate are weighed in proportion and added to the first stirring tank, and the temperature in the first stirring tank is raised to 130 °C to Stir at a stirring speed of 400r / min for 6h to obtain the first mixed solution, and cool to below 40°C for later use;

[0056] Step 2. Weigh the proportions of terpene resin, methyl acetate and propylene glycol methyl ether acetate and add them into the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com