High-temperature-resistant adhesive tape and preparation method thereof

A high-temperature-resistant adhesive and high-temperature-resistant technology, used in adhesives, polymer adhesive additives, and non-polymer adhesive additives, etc., can solve the problems of lower part processing yield, lower high temperature resistance effect, and unfavorable production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

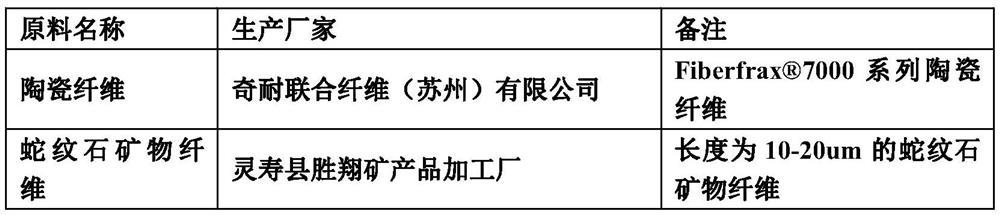

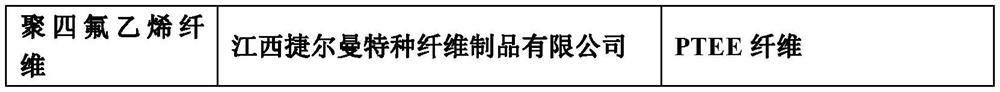

[0058] A modified serpentine mineral fiber is prepared by the following method:

[0059] Step 1: 10kg serpentine mineral fiber (length is 10um), 5kg polytetrafluoroethylene fiber (length is 20um), 500g diacrylate-1,4-butylene glycol ester, 800g sodium lauryl sulfate and 20kg deionized Water, stirred evenly, heated to 60°C, ultrasonicated for 2 hours, and the ultrasonic frequency was set to 25KHz.

[0060] Step 2: filter and dry, add 10% nano-alumina by weight to the dried product, mix evenly, roast at 150° C. for 2 hours, and cool to room temperature to obtain modified serpentine mineral fiber.

preparation example 2

[0062] A modified serpentine mineral fiber is prepared by the following method:

[0063] Step 1: 10kg serpentine mineral fiber (length is 15um), 6kg polytetrafluoroethylene fiber (length is 10um), 600g diacrylate-1,4-butylene glycol ester, 700g sodium lauryl sulfate and 22kg deionized Water, stirred evenly, heated to 65°C, ultrasonicated for 1.5h, and the ultrasonic frequency was set to 22KHz.

[0064] Step 2: filter and dry, add 12% nano-alumina by weight to the dried product, mix evenly, and roast at 160° C. for 3 hours, and cool to room temperature to obtain modified serpentine mineral fiber.

preparation example 3

[0066] A modified serpentine mineral fiber is prepared by the following method:

[0067] Step 1: 10kg serpentine mineral fiber (length is 20um), 5.5kg polytetrafluoroethylene fiber (length is 15um), 700g diacrylate-1,4-butylene glycol ester, 600g sodium lauryl sulfate and 25kg go Ionized water, stirred evenly and heated, heated to 70°C, ultrasonicated for 2.5h, and the ultrasonic frequency was set to 27KHz.

[0068] Step 2: filter and dry, add 15% of the weight of the dried product to the nano-alumina, mix evenly, and roast at 165° C. for 2.5 hours, and cool to room temperature to obtain modified serpentine mineral fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com