Catalyst for carbon dioxide hydrogenation and toluene aromatic ring alkylation as well as preparation method and application of catalyst

A carbon dioxide and aromatic cycloalkane technology, which is applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems of low yield of xylene and low conversion rate of toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

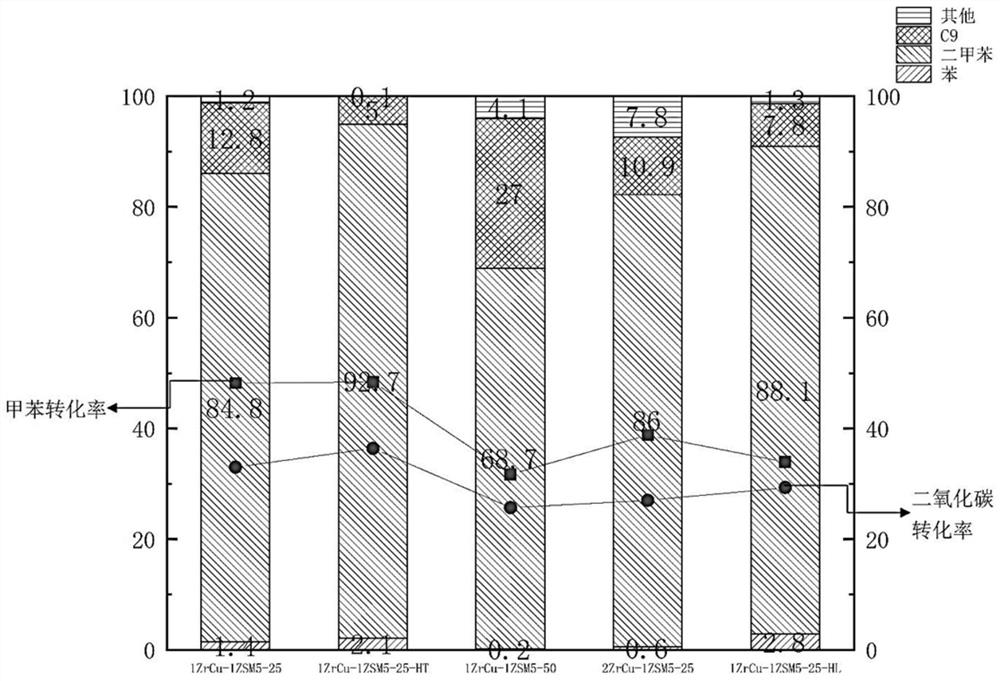

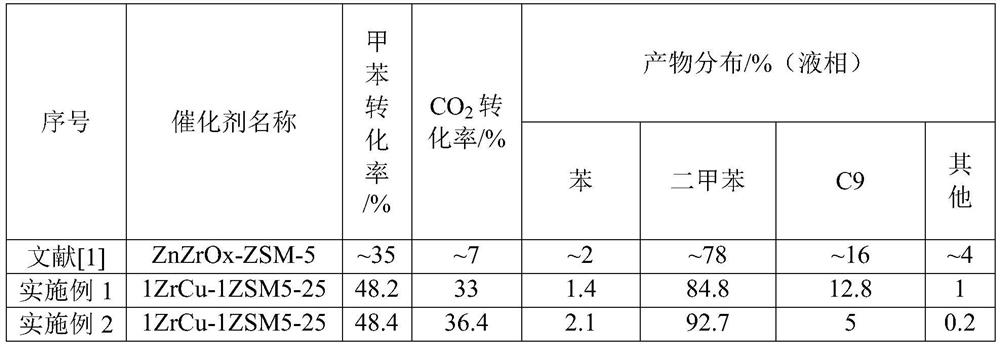

Examples

Embodiment 1

[0059] Preparation of 1ZrCu-1ZSM5-25 catalyst (the mass ratio of ZrCu oxide to ZSM-5 molecular sieve is 1:1, and the SAR of ZSM-5 is 25)

[0060] First, weigh copper nitrate and zirconium nitrate solids with a stoichiometric ratio of Cu:Zr=9:1, dissolve them in ethanol to form an ethanol solution with a cation concentration of 1M, and record it as solution I, and then weigh oxalic acid to prepare a 0.5M ethanol solution to obtain For solution II, under the condition of constant stirring, add solution I dropwise to solution II at a rate of 3 ml / min, and react for 30 minutes after the dropwise addition is completed to obtain solution III. Suction filter the solution Ⅲ, put the filter cake in an oven at 120°C for 8 hours overnight to dry, and obtain the precursor I, grind the precursor I and put it into a muffle furnace under air condition at a heating rate of 5°C / min Calcined at 400°C for 3h to obtain precursor II. Add HZSM-5 with SAR=25 into the cyclohexane solution of TEOS, s...

Embodiment 2

[0063] Preparation of 1ZrCu-1ZSM5-25-HT catalyst (the mass ratio of ZrCu oxide to ZSM-5 molecular sieve is 1:1, and the SAR of ZSM-5 is 25)

[0064] First, weigh copper nitrate and zirconium nitrate solids with a stoichiometric ratio of Cu:Zr=9:1, dissolve them in ethanol to form an ethanol solution with a cation concentration of 1M, and record it as solution I, and then weigh oxalic acid to prepare a 0.5M ethanol solution to obtain For solution II, under the condition of constant stirring, add solution I dropwise to solution II at a rate of 3 ml / min, and react for 30 minutes after the dropwise addition is completed to obtain solution III. Suction filter the solution Ⅲ, put the filter cake in an oven at 120°C for 8 hours overnight to dry, and obtain the precursor I, grind the precursor I and put it into a muffle furnace under air condition at a heating rate of 5°C / min Calcined at 400°C for 3h to obtain precursor II. Add HZSM-5 with SAR=25 into the cyclohexane solution of TEOS...

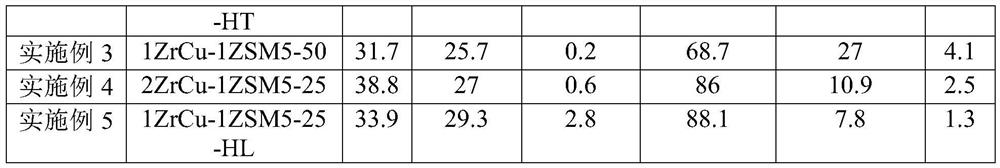

Embodiment 3

[0067] Preparation of 1ZrCu-1ZSM5-50 catalyst (the mass ratio of ZrCu oxide to ZSM-5 molecular sieve is 1:1, and the SAR of ZSM-5 is 50)

[0068] First, weigh copper nitrate and zirconium nitrate solids with a stoichiometric ratio of Cu:Zr=9:1, dissolve them in ethanol to form an ethanol solution with a cation concentration of 1M, and record it as solution I, and then weigh oxalic acid to prepare a 0.5M ethanol solution to obtain For solution II, under the condition of constant stirring, add solution I dropwise to solution II at a rate of 3 ml / min, and react for 30 minutes after the dropwise addition is completed to obtain solution III. Suction filter the solution Ⅲ, put the filter cake in an oven at 120°C for 8 hours overnight to dry, and obtain the precursor I, grind the precursor I and put it into a muffle furnace under air condition at a heating rate of 5°C / min Calcined at 400°C for 3h to obtain precursor II. Add HZSM-5 with SAR=50 into the cyclohexane solution of TEOS, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com