Display device, polyimide precursor composition, polyimide film, and laminate

A polyimide precursor and polyimide film technology, which is applied in the directions of instruments, optics, identification devices, etc., can solve the problems of increasing the thermal expansion coefficient of the polyimide film, reducing the heat resistance, and increasing the production cost. , to achieve the effects of excellent mechanical properties, improved transmittance and low haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

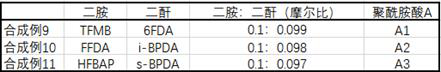

[0036] The synthesis of the polymer B in the present invention includes the steps of reacting one or more diazoacetate monomers under the action of a transition metal-containing catalyst at 20-80°C, and then reprecipitating. Further, the synthesis method of the polymer B in the present invention comprises the steps of: dispersing the transition metal-containing catalyst in the solvent F, and then dropping the diazoacetate monomer into the solvent F, and reacting for 24 hours, the obtained The product was reprecipitated in solvent G to obtain polymer B powder.

[0037] In the present invention, the chemical formula of the polymerization of diazoacetate monomers to generate polymer B is shown in the following formula (3):

[0038] Formula (3)

[0039] R in formula (3)1 for hydrogen.

[0040] The monomer used for synthesizing polymer B in the present invention is diazoacetate monomer, can enumerate example: diazoacetate methyl ester, diazoacetate ethyl ester, diazoacetate ter...

Synthetic example 1

[0097] Under dry nitrogen flow, 1.00 g of copper dichloride catalyst was added to 100 mL of chloroform and kept stirring, the reaction temperature was raised to 60 ° C, and then 100.00 g of EDA was added dropwise to the reaction system, and the reaction After 24 hours, after the reaction, filter out the catalyst, use the mixture of diethyl ether and cyclohexane (1:1) as a precipitant to obtain a white flocculent precipitate, and further vacuum dry the precipitate to obtain polymer B1, the weight average molecular weight for 5087. The reaction equation is shown in the following formula (5).

[0098] Formula (5)

Synthetic example 2

[0100] Only by adjusting the amount of EDA added in Synthesis Example 1 to 150 g, polymer B2 can be obtained with a weight average molecular weight of 8526.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com