Pyrolysis device and pyrolysis method for infrared pyrolysis of red mud catalyzed biomass

A biomass and infrared heat technology, applied in the direction of biofuel, coke oven heating, combustible gas purification, etc., can solve the problems of increased processing costs, atmospheric environmental pollution, waste of hydrocarbon energy, etc., to reduce pyrolysis by-products, Good pyrolysis effect and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

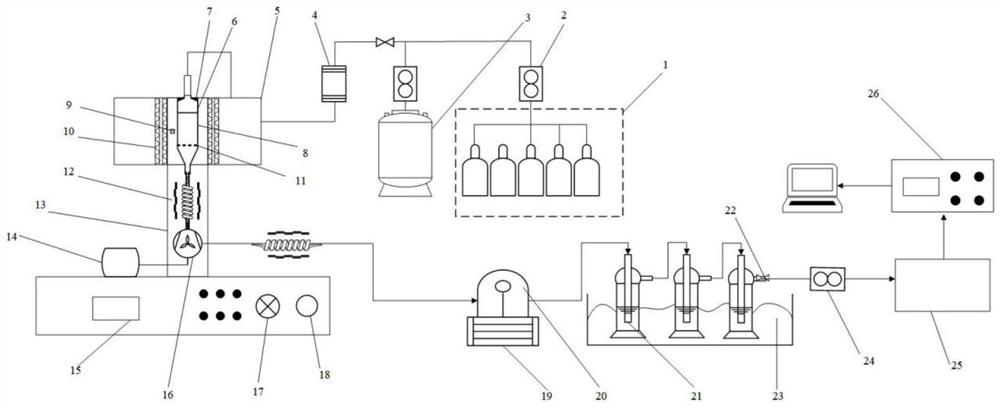

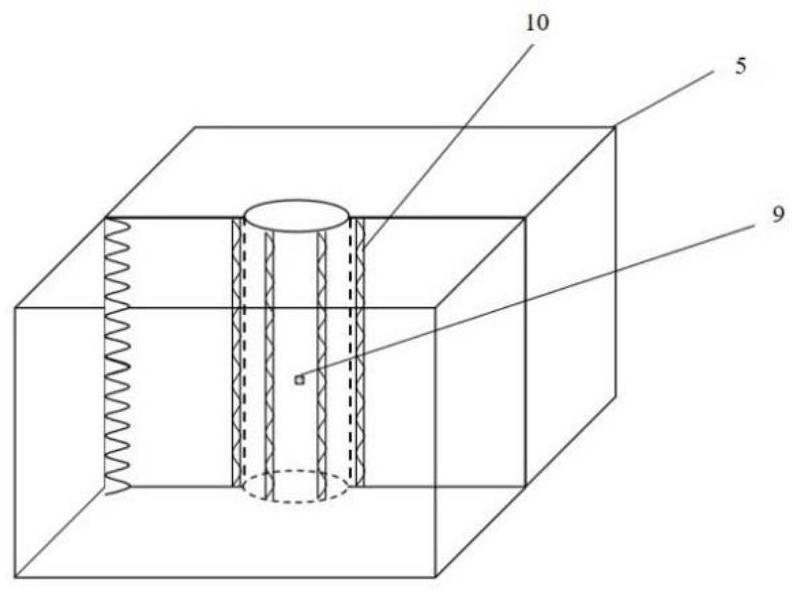

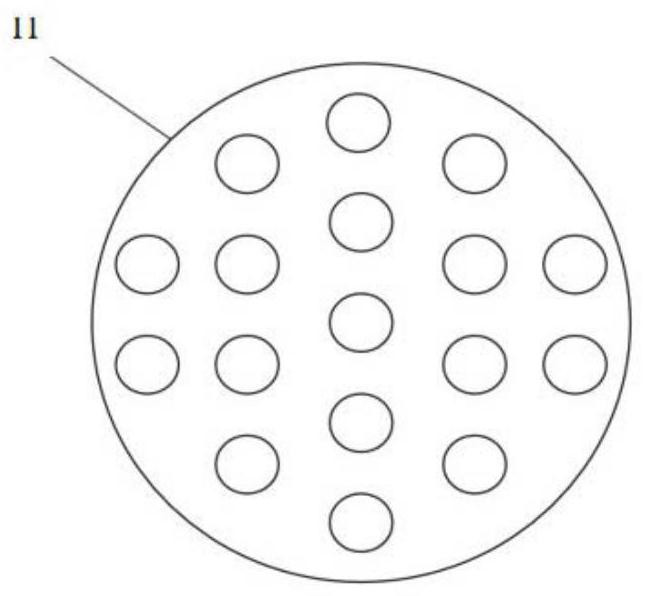

[0036] like Figure 1 to Figure 3 As shown, the red mud catalyzed biomass infrared pyrolysis pyrolysis device according to the present invention has components including a gas supply system, a pyrolysis reaction system, a product detection and recovery system. The specific structure and connection relationship of the components are:

[0037]The gas supply system includes a gas cylinder 1, a gas mass flow meter 2, a steam generator 3, and a mixed gas preheater 4, all of which are connected by a stainless steel air duct with a diameter of 3 to 5 mm. The gas mass flowmeter 2 is connected, the gas mass flowmeter 2 is connected to the inlet pipe of the gas preheater 4 through the gas guide pipe, the steam generator 3 is connected to the second gas mass flowmeter 2-1, and the second gas mass flowmeter 2-1 The other end is connected to the inlet pipe of the mixed gas preheater 4, the outlet pipe of the mixed gas preheater 4 is connected to the inlet of the heater 5, and the outlet o...

Embodiment 2

[0043] An example of a pyrolysis method suitable for the pyrolysis device of the red mud catalytic biomass infrared pyrolysis, the pyrolysis device is connected according to the connection method described in Example 1, and 100 g of dried biomass is added to On the reaction plate 11 of the reactor 8, the gas that enters the gas cylinder 1 is preferably nitrogen, that is, biomass is pyrolyzed under a nitrogen atmosphere, and the gas flow rate is 200ml / min. First, check the airtightness of the device and open the gas outlet valve 22. Adjust the temperature of the mixed gas preheater 4 to 300°C, the temperature of the steam generator 3 to 120°C, and the temperature of the heater 5 to 600°C. When all the adjusted temperatures rise to the adjusted temperature, the biomass in the reactor 8 The pyrolysis reaction starts, and the coke in the obtained product is about 24.33%, the tar product is about 40.82%, and the gas product is about 28.75%.

Embodiment 3

[0045] Another example of a pyrolysis method suitable for the red mud catalyzed biomass infrared pyrolysis pyrolysis device, the pyrolysis device is connected according to the connection method described in Example 1, and the gas in the gas cylinder is preferably nitrogen , that is, pyrolyze under a nitrogen atmosphere, take the nitrogen flow rate of 200ml / min, first check the airtightness of the device, open the gas outlet valve 22, adjust the temperature of the mixed gas preheater 4 to 300°C, and adjust the temperature of the steam generator 3 to 120°C, when all the adjusted temperatures rise to the adjusted temperature, the biomass is crushed to 0.2-0.45mm, the red mud is ground to below 200 mesh, and a total of 200g of dried red mud and biomass are added to the reactor 8 On the reaction plate 11, turn on the heater 5 for pyrolysis, the temperature of the heater 5 is 600°C; the ratio of biomass to red mud is 1:1, the coke in the obtained product is about 25.23%, the tar prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com