Polyolefin-based high-barrier film with renewable structure and preparation method of polyolefin-based high-barrier film

A polyolefin-based, barrier film technology, applied in the field of polymer processing, can solve the problems of unfavorable film recycling, difficult separation, complex process, etc., achieve excellent gas barrier properties, improve interface adhesion, and increase the effect of diffusion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

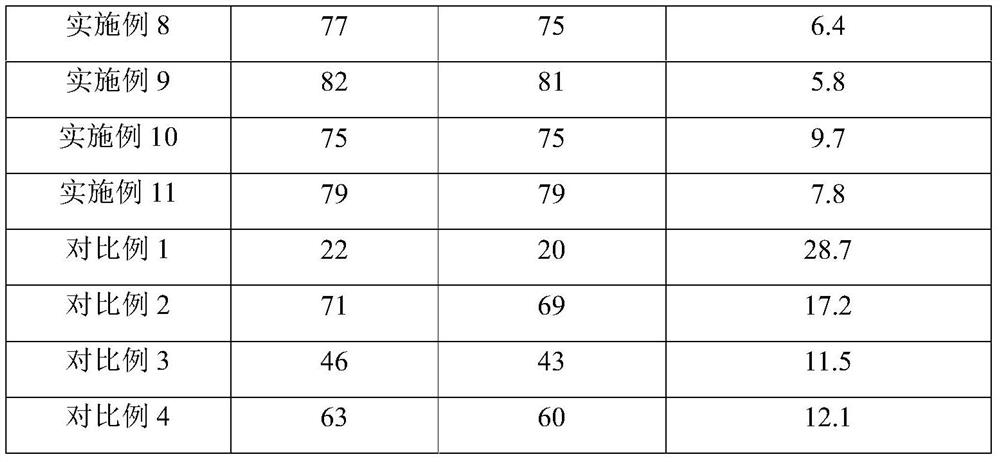

Examples

Embodiment 1

[0036] 60 parts of low-density polyethylene after drying, 40 parts of polyglycolic acid, 8 parts of compatibilizers, 0.3 parts of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester Stir in a high-speed mixer for 2 minutes, put into an extruder for continuous melt extrusion and granulation, the temperature of the screw is 220° C., and the rotational speed of the screw is 200 rpm. The dried pellets were extruded into flakes through a screw extruder and rapidly cooled to 30°C, and the screw temperature was 230°C. A polyolefin-based barrier film with a renewable structure can be obtained by biaxially stretching the cooled sheet using a flat film biaxial stretching process, followed by heat treatment and cooling to room temperature. The stretching temperature is 70 °C and the heat treatment temperature is 100 °C. ℃, the transverse stretching ratio is 7 times, and the longitudinal stretching ratio is 7 times. The compatibilizer is maleic anhydride gra...

Embodiment 2

[0038] 70 parts of low-density polyethylene after drying, 30 parts of polyglycolic acid, 8 parts of compatibilizer, 0.3 part of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester Stir in a high-speed mixer for 2 minutes, put into an extruder for continuous melt extrusion and granulation, the temperature of the screw is 220° C., and the rotational speed of the screw is 200 rpm. The dried pellets were extruded into flakes through a screw extruder and rapidly cooled to 30°C, and the screw temperature was 230°C. A polyolefin-based barrier film with a renewable structure can be obtained by biaxially stretching the cooled sheet using a flat film biaxial stretching process, followed by heat treatment and cooling to room temperature. The stretching temperature is 70 °C and the heat treatment temperature is 100 °C. ℃, the transverse stretching ratio is 7 times, and the longitudinal stretching ratio is 7 times. The compatibilizer is maleic anhydride graft...

Embodiment 3

[0040] 80 parts of low-density polyethylene after drying, 20 parts of polyglycolic acid, 5 parts of compatibilizer, 0.3 part of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester Stir in a high-speed mixer for 2 minutes, put into an extruder for continuous melt extrusion and granulation, the temperature of the screw is 220° C., and the rotational speed of the screw is 200 rpm. The dried pellets were extruded into flakes through a screw extruder and rapidly cooled to 30°C, and the screw temperature was 230°C. A polyolefin-based barrier film with a renewable structure can be obtained by biaxially stretching the cooled sheet using a flat film biaxial stretching process, followed by heat treatment and cooling to room temperature. The stretching temperature is 70 °C and the heat treatment temperature is 100 °C. ℃, the transverse stretching ratio is 7 times, and the longitudinal stretching ratio is 7 times. The compatibilizer is maleic anhydride graft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com