Resin-based composite material thermo-oxidative aging prevention structure and preparation method thereof

A composite material and resin-based technology, which is applied in the field of resin-based composite material anti-thermal and oxidative aging structure and its preparation, can solve the problems of resin-based materials such as easy oxidation, decreased mechanical properties, and low service life, so as to reduce the aging rate and porosity. The effect of low efficiency and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

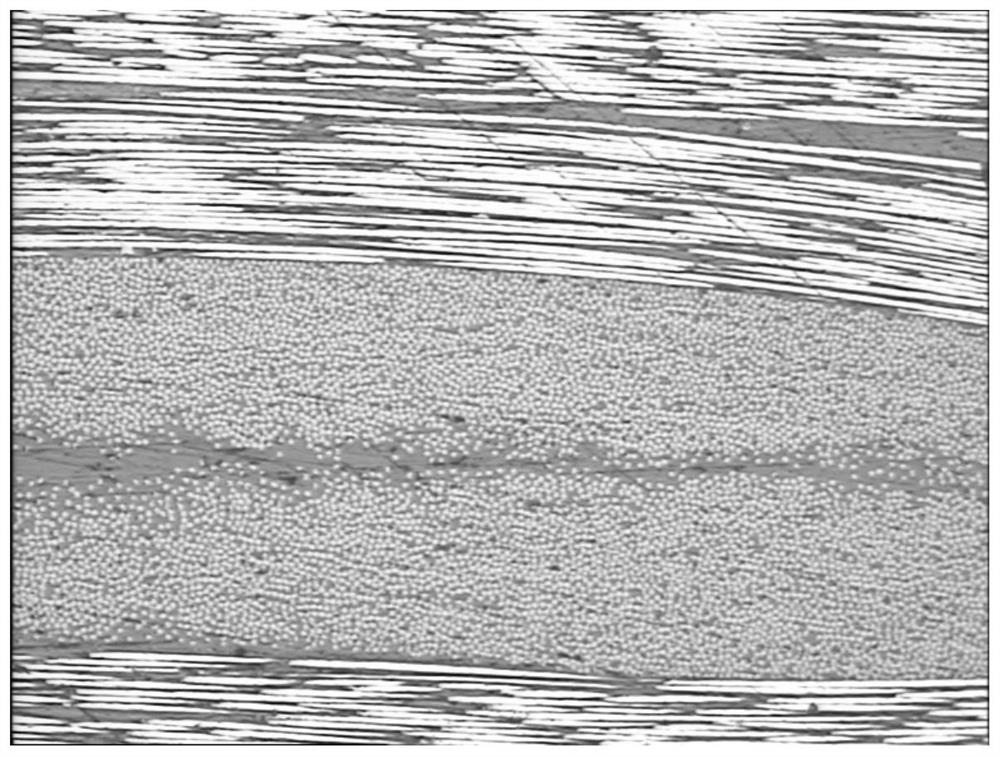

[0050] Embodiment 1 provides that the resin-based composite material provided by the present invention is a flat plate structure, including a resin-based composite material and a thermal-oxidative aging-resistant film layer; the resin-based composite material and the thermal-oxidative aging-resistant film layer both have The bonding surface, the bonding surface of the heat-oxidative aging-resistant film layer and the bonding surface of the resin-based composite material are bonded and cured as one; the heat-oxidative aging-resistant mold layer is a polyimide film layer; the heat-resistant The bonding surface of the oxygen aging film layer is roughened.

[0051] The thickness of the polyimide film layer is 50 microns.

[0052] The elongation at break of the polyimide film was 80%.

[0053] The tensile strength of the polyimide film is 240MPa.

[0054] The 5% weight loss temperature of the polyimide film in nitrogen is 590°C. The roughening treatment is supercritical CO 2 Sp...

Embodiment 2

[0082] Embodiment 2 provides that the resin-based composite material provided by the present invention is a flat plate structure, including a resin-based composite material and a thermal-oxidative aging-resistant film layer; the resin-based composite material and the thermal-oxidative aging-resistant film layer both have The joint surface, the joint surface of the heat-oxidative aging-resistant film layer and the joint surface of the resin-based composite material are bonded and cured as one; the heat-oxidative aging-resistant mold layer is a polyimide film layer; the heat-resistant The bonding surface of the oxygen aging film layer is roughened.

[0083] The thickness of the polyimide film layer is 50 microns.

[0084] The elongation at break of the polyimide film was 80%.

[0085] The tensile strength of the polyimide film is 240MPa.

[0086] The 5% weight loss temperature of the polyimide film in nitrogen is 590°C.

[0087] The roughening treatment is supercritical CO 2...

Embodiment 3

[0106] Embodiment 3, the resin-based composite material anti-thermal oxygen aging structure provided by the present invention is a ring structure, including the resin-based composite material and the thermal-oxidative aging-resistant film layer; the resin-based composite material and the thermal-oxidative aging resistant film layer both have The joint surface, the joint surface of the heat-oxidative aging-resistant film layer and the joint surface of the resin-based composite material are bonded and cured as one; the heat-oxidative aging-resistant mold layer is a polyimide film layer; the heat-resistant The bonding surface of the oxygen aging film layer is roughened.

[0107] The thickness of the polyimide film layer is 50 microns.

[0108] The elongation at break of the polyimide film was 80%.

[0109] The tensile strength of the polyimide film is 240MPa.

[0110] The 5% weight loss temperature of the polyimide film in nitrogen is 590°C.

[0111] The roughening treatment i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com