Transparent polyimide containing hydrogen bonds as well as preparation method and application of transparent polyimide

A technology of transparent polyimide and hydrogen bonding, which is applied in the field of high-performance transparent polyimide film materials and its preparation, and can solve the problems of low CTE heat resistance, solvent resistance, low heat resistance, poor solvent resistance, etc. problems, to achieve excellent solvent resistance, excellent thermal stability, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

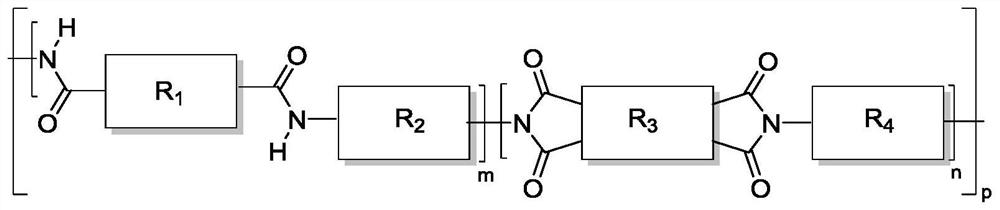

Method used

Image

Examples

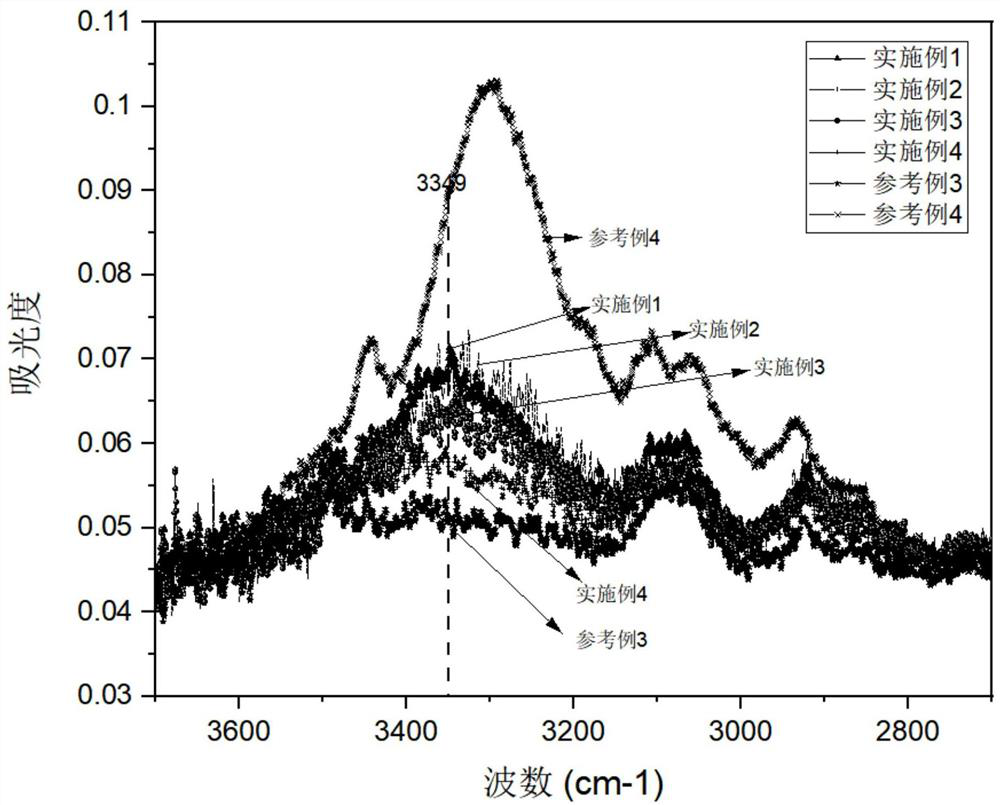

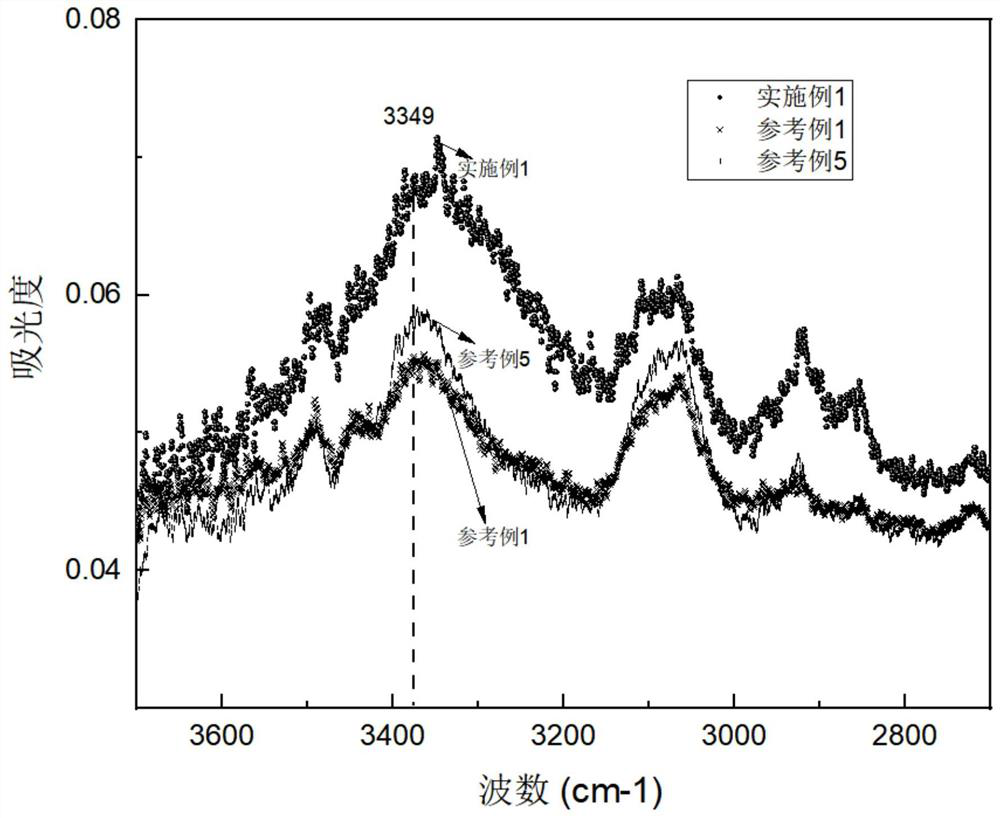

Embodiment 1

[0072]Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl TFDB (1.6172g, 5.05mmol) and biphenyltetracarboxylic dianhydride in a three-necked flask equipped with mechanical stirring BPDA (1.4711g, 5mmol), ensure that the molar ratio of TFDB and BPDA is 1.01:1, add anhydrous dimethylacetamide DMAc (20mL), make the solution solid content be 13%, react at room temperature for 5 hours; Add TFDB ( 0.6244g, 1.95mmol) and 9.5mL DMAc, after TFDB is completely dissolved, add terephthaloyl dichloride TPC (0.4060g, 2mmol) to form a gel, then add propylene oxide (0.6mL, 16.8mmol), and react at room temperature After 3 hours, a polyamic acid-polyamide solution with a solid content of 13% was obtained, which was transferred to a refrigerator at 0° C. and stored overnight. Then scrape it onto a glass plate, heat it at a temperature of 60°C to 300°C at a rate of 1-10°C / min for 2-10 hours, and cool to room temperature to obtain transparent polyimide with a thickness of 5...

Embodiment 2

[0075] Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl TFDB (1.7773g, 5.55mmol) and biphenyltetracarboxylic dianhydride to a three-necked flask equipped with mechanical stirring BPDA (1.6182g, 5.5mmol), ensure that the molar ratio of TFDB to BPDA is 1.01:1, add anhydrous dimethylacetamide DMAc (24mL) to make the solution solid content 13%, react at room temperature for 5 hours; then add TFDB (0.4643g, 1.45mmol) and 9.5mL DMAc, after TFDB is completely dissolved, add terephthaloyl dichloride TPC (0.3045g, 1.5mmol), form a gel, then add propylene oxide (0.45mL, 12.6mmol), React at room temperature for 3 hours to obtain a polyamic acid-polyamide solution with a solid content of 13%, which was transferred to a refrigerator at 0° C. for overnight storage. Then scrape it onto a glass plate, heat it at a temperature of 60°C to 300°C at a rate of 1-10°C / min for 2-10 hours, and cool to room temperature to obtain transparent polyimide with a thickness of 50 μ...

Embodiment 3

[0077] Under nitrogen protection, add 4,4'-diamino-2,2'-bistrifluoromethylbiphenyl TFDB (1.9374g, 6.05mmol) and biphenyltetracarboxylic dianhydride to a three-necked flask equipped with mechanical stirring BPDA (1.7653g, 6mmol), ensure that the molar ratio of TFDB to BPDA is 1.01:1, add anhydrous dimethylacetamide DMAc (26.5mL), so that the solid content of the solution is 13%, react at room temperature for 5 hours; then add TFDB (0.3362g, 0.95mmol) and 9.5mL DMAc, after TFDB is completely dissolved, add terephthaloyl dichloride TPC (0.2030g, 1mmol) to form a gel, then add propylene oxide (0.3mL, 8.4mmol), room temperature After reacting for 3 hours, a polyamic acid-polyamide solution with a solid content of 13% was obtained, which was transferred to a refrigerator at 0° C. for overnight storage. Then scrape it onto a glass plate, heat it at a temperature of 60°C to 300°C at a rate of 1-10°C / min for 2-10 hours, and cool to room temperature to obtain transparent polyimide with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com