A high-entropy yttrium pyrochlore ceramic with glass-like thermal conductivity and its preparation method

A technology of thermal conductivity and pyrochlore, which is applied in the field of ceramic materials, can solve problems such as thermal conductivity of unregulated materials, achieve the effect of expanding the composition range and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The invention provides a preparation method of high-entropy yttrium pyrochlore ceramics with glass-like thermal conductivity, which specifically comprises the following steps;

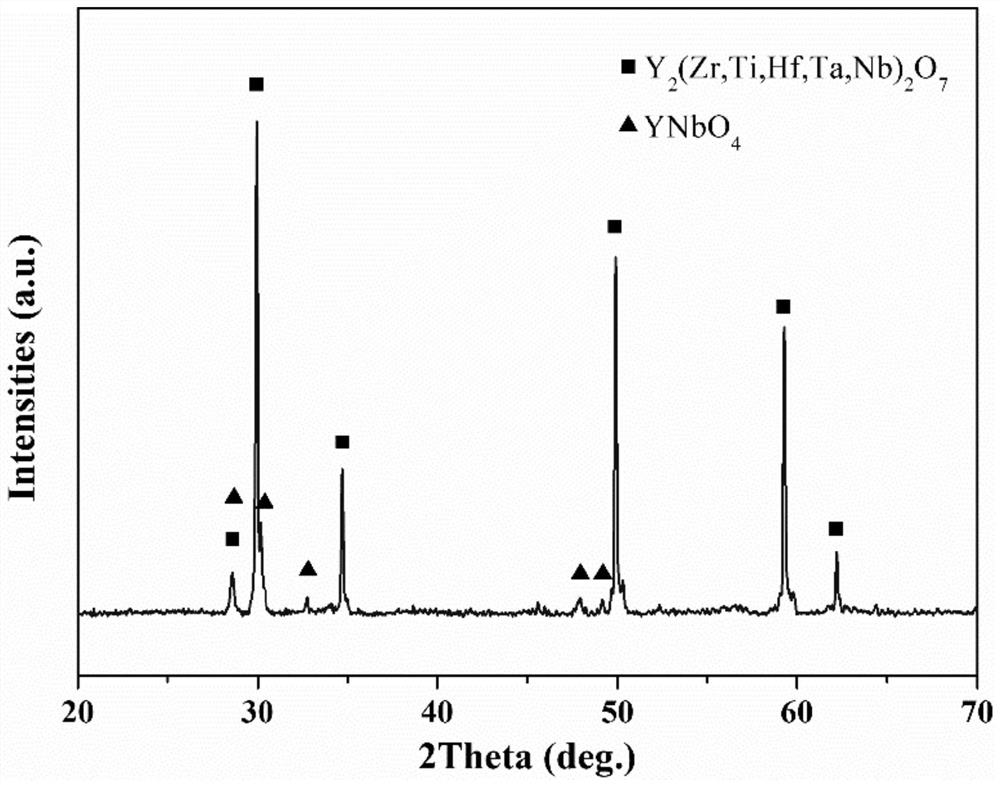

[0031] Step 1: Take Y with an average particle size of 0.1 μm and a chemical purity greater than 98.0% 2 O 3 Powder, ZrO 2 Powder, HfO 2 Powder, TiO 2 Powder, Ta 2 O 5 Powder and Nb 2 O 5 Powder, 38.4% Y according to the molar content 2 O 3Powder, with 15.4% molar content of ZrO 2 Powder, 15.4% HfO 2 Powder, 15.4% TiO 2 Powder, 7.7% Ta 2 O 5 Powder and 7.7% Nb 2 O 5 4-5 powders in the powder are mixed by ball milling; the ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 8h; the mixed powder is dried and granulated , After passing through a 200-mesh sieve, the green body is obtained by bidirectional pressurization and the pressure is 100MPa;

[0032] St...

Embodiment 2

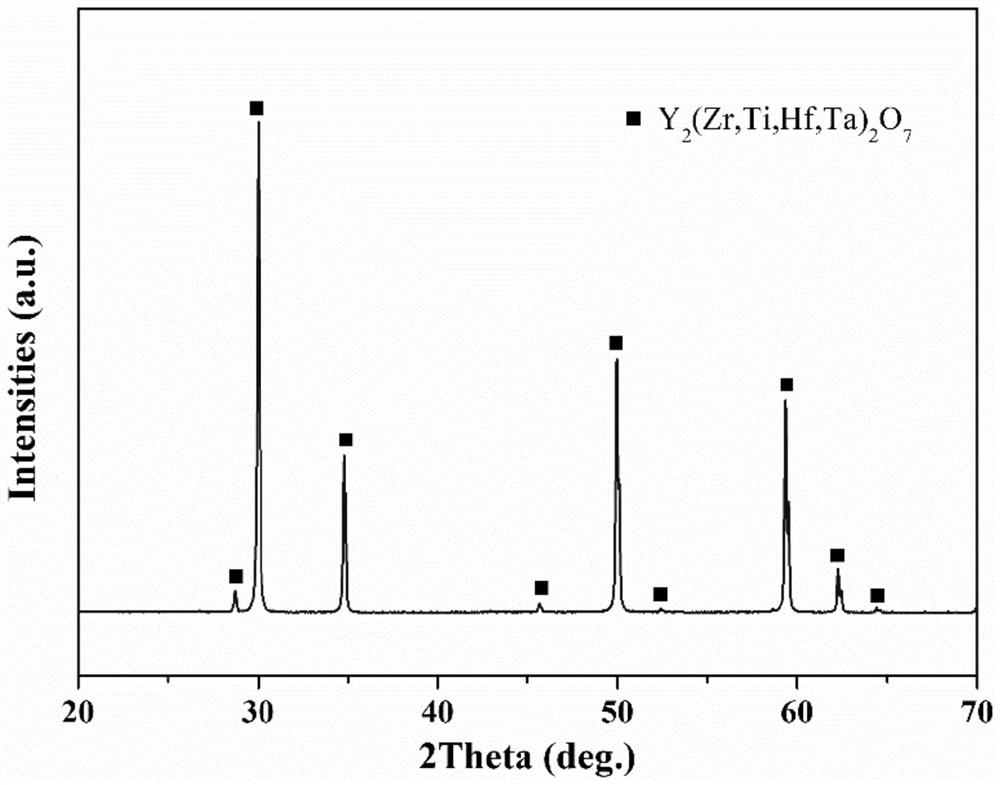

[0035] The invention provides a preparation method of high-entropy yttrium pyrochlore ceramics with glass-like thermal conductivity, which specifically comprises the following steps;

[0036] Step 1: Take Y with an average particle size of 0.1 μm and a chemical purity greater than 98.0% 2 O 3 Powder, ZrO 2 Powder, HfO 2 Powder, TiO 2 Powder, Ta 2 O 5 Powder and Nb 2 O 5 Powder, 38.4% Y according to the molar content 2 O 3 Powder, with 15.4% molar content of ZrO 2 Powder, 15.4% HfO 2 Powder, 15.4% TiO 2 Powder, 7.7% Ta 2 O 5 Powder and 7.7% Nb 2 O 5 4-5 kinds of powders in the powder are mixed by ball milling; the ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 10h; the mixed powder is dried and granulated , After passing through a 200-mesh sieve, the green body is obtained by bidirectional pressurization and the pressure is 100MPa; ...

Embodiment 3

[0040] The invention provides a preparation method of high-entropy yttrium pyrochlore ceramics with glass-like thermal conductivity, which specifically comprises the following steps;

[0041] Step 1: Take Y with an average particle size of 0.1 μm and a chemical purity greater than 98.0% 2 O 3 Powder, ZrO 2 Powder, HfO 2 Powder, TiO 2 Powder, Ta 2 O 5 Powder and Nb 2 O 5 Powder, 38.4% Y according to the molar content 2 O 3 Powder, with 15.4% molar content of ZrO 2 Powder, 15.4% HfO 2 Powder, 15.4% TiO 2 Powder, 7.7% Ta 2 O 5 Powder and 7.7% Nb 2 O 5 4-5 kinds of powders in the powder are mixed by ball milling; the ball milling method is wet roller ball milling, ethanol is the ball milling medium, yttrium-stabilized zirconia balls are the grinding balls, and the ball milling mixing time is 12h; the mixed powder is dried and granulated , After passing through a 200-mesh sieve, the green body is obtained by pressing in two directions and the pressure is 30MPa;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com