Irradiation on-line internal friction in-situ measurement device

An in-situ measurement and irradiation technology, applied in the field of irradiation measurement, can solve problems such as in-situ monitoring of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

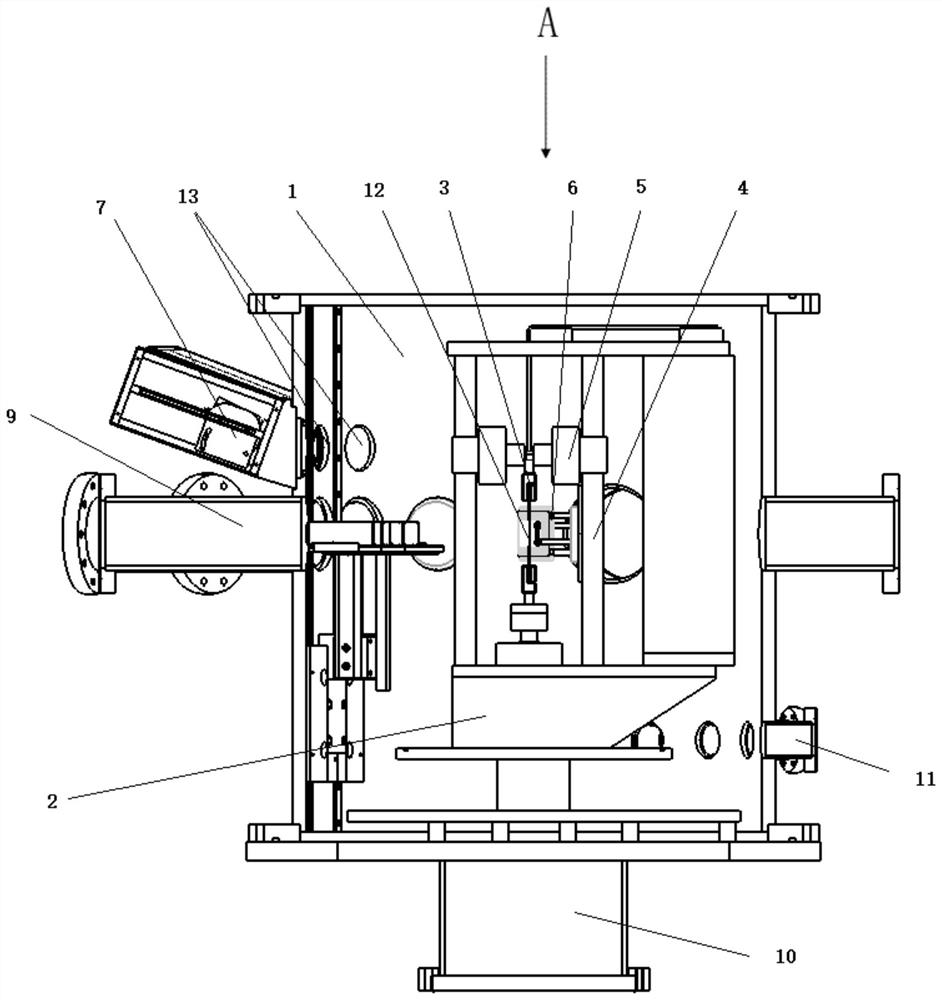

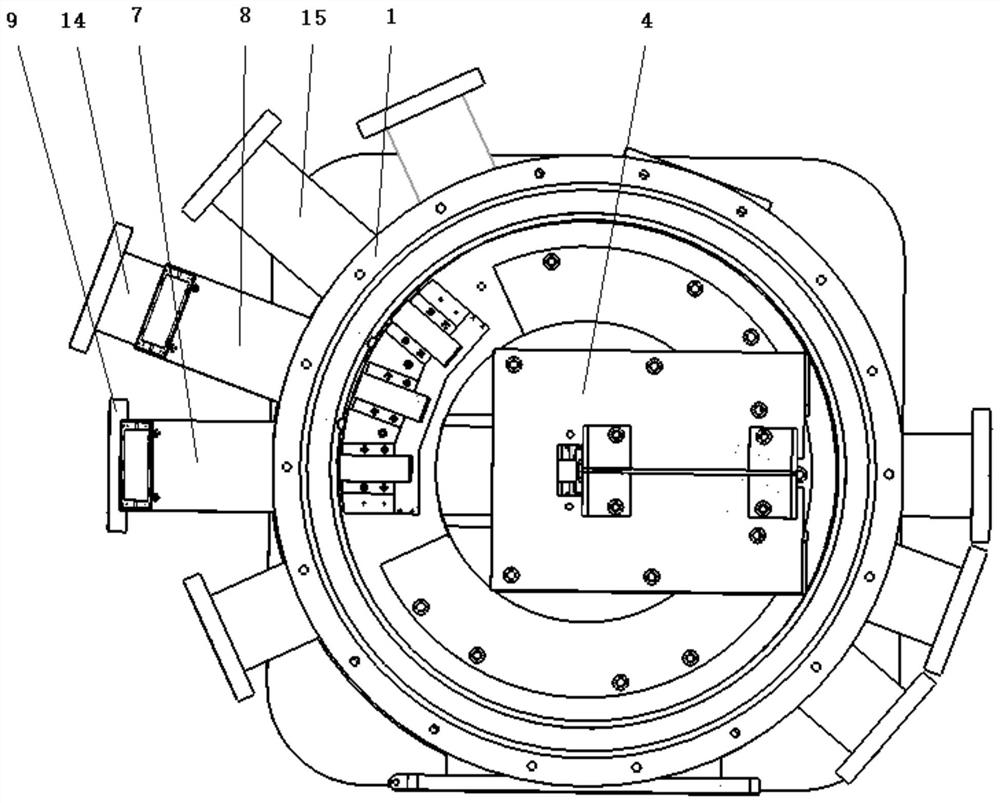

[0026] Such as figure 1 , figure 2 As shown, the present invention provides an irradiation on-line internal friction in-situ measuring device, which includes a sealed vacuum chamber 1 provided with a heavy ion beam flow pipe 9, and the inside of the vacuum chamber 1 is used to set an irradiation sample 12 and The irradiated sample 12 can be heated, the accelerated heavy ion beam can be irradiated into the irradiated sample 12 through the heavy ion beam flow pipe 9 , and a displacement detector 7 for measuring the displacement change of the irradiated sample 12 is also included.

[0027] The bottom of the vacuum chamber 1 is provided with a vacuum pump pumping interface 10, which is used to connect the vacuum pumping system to vacuum the vacuum chamber 1.

[0028] The interior of the vacuum chamber 1 (at the center of the bottom) is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com