Mask manufacturing method and mask

A production method and mask technology, applied in the field of masks, can solve the problems of short service life and increased breathing resistance of masks, and achieve the effects of extending the validity period, reducing the filtration resistance and improving the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

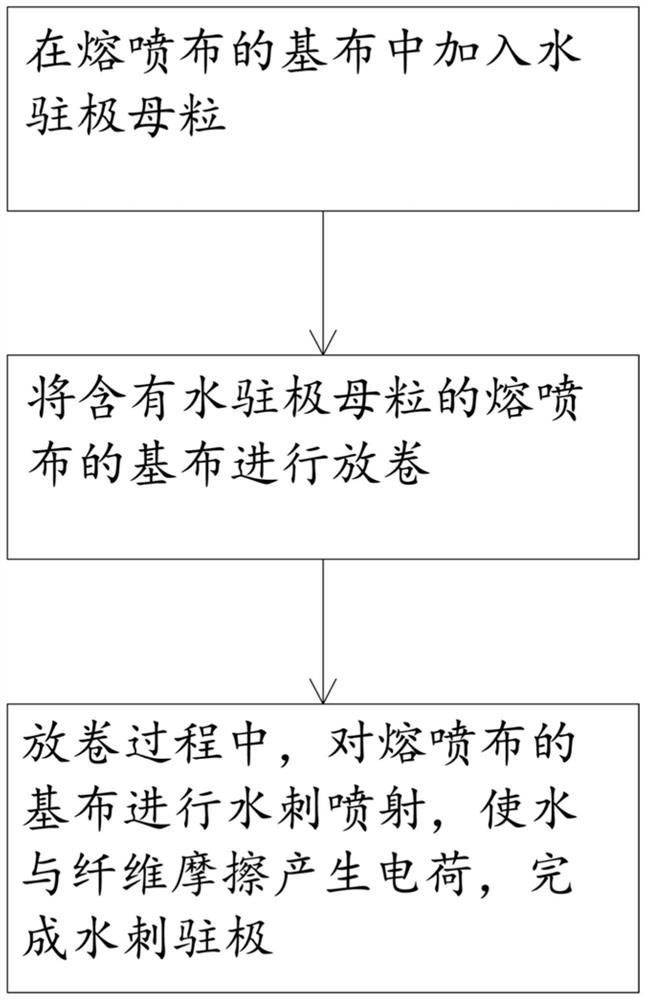

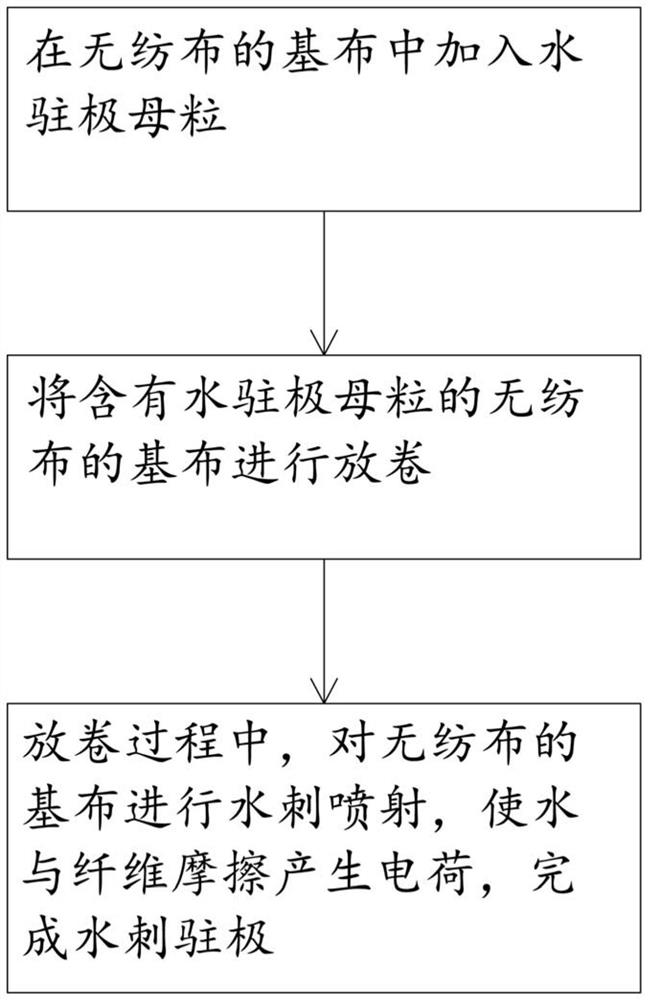

[0025] The mask production method proposed in the embodiment of the present invention includes firstly making the melt-blown cloth with thick fibers and thin fibers, and then subjecting the melt-blown cloth to an electrostatic treatment process of water electret. Since the melt-blown cloth uses thick fibers, the filter resistance of the melt-blown cloth is reduced, the melt-blown cloth is not easy to be blocked, and the dust holding capacity is increased. At the same time, the thick fiber increases the electrostatic adsorption area of the melt-blown cloth, so water electret is used After the advanced electrostatic treatment process, the electrostatic retention of the melt-blown cloth is more than 3 times that of the electro-electret, and the filtration efficiency of the mask after high temperature, high humidity, and aging tests hardly decreases, ensuring the filtration efficiency, so that the mask has low resistance and high The filtration efficiency improves the use time of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com