Continuous forming method and device for deep blind hole shell with pulse current assisted partial upsetting

A pulse current, deep blind hole technology, used in forging/pressing/hammer devices, manufacturing tools, other household appliances, etc. Good plasticity, increasing cumulative deformation, and reducing deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

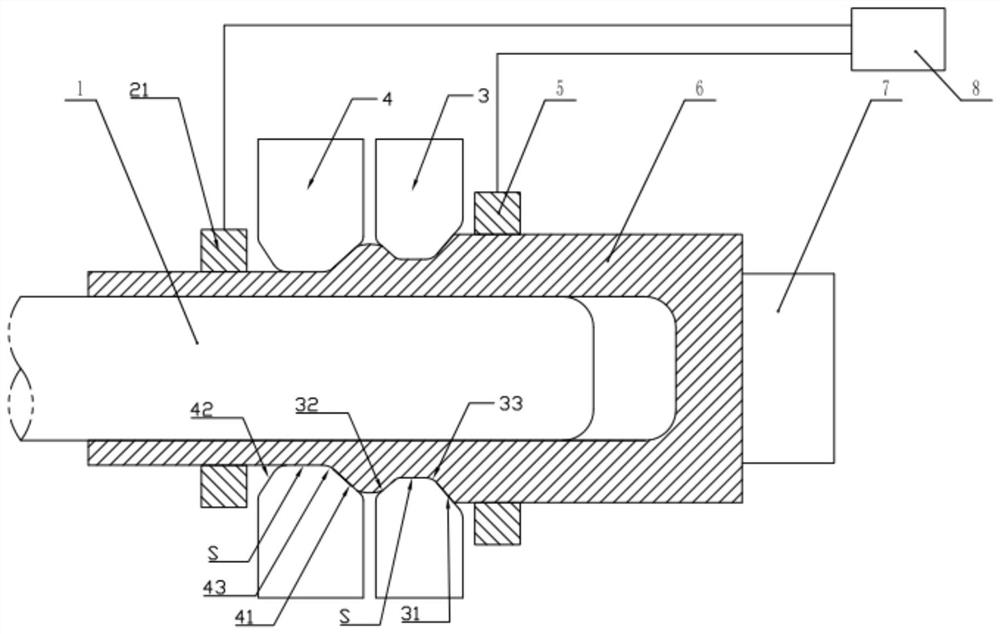

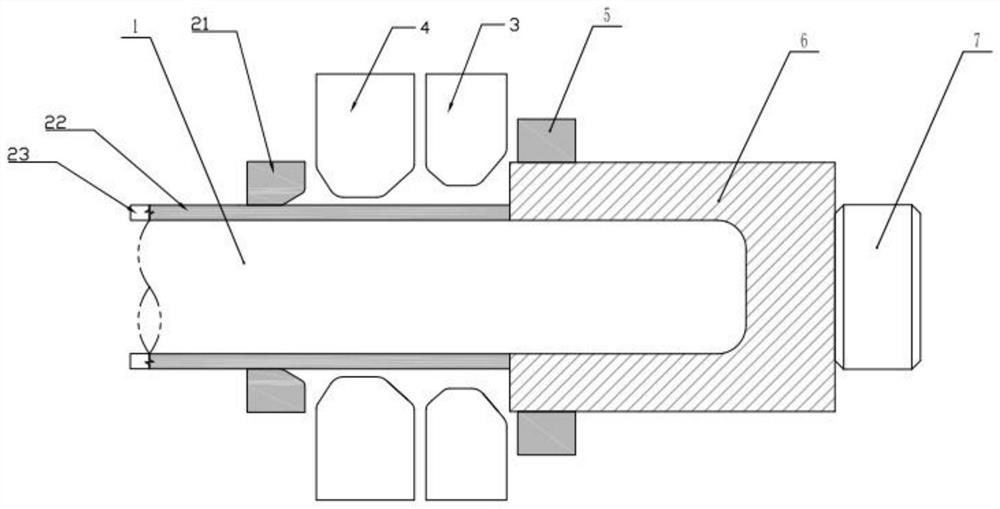

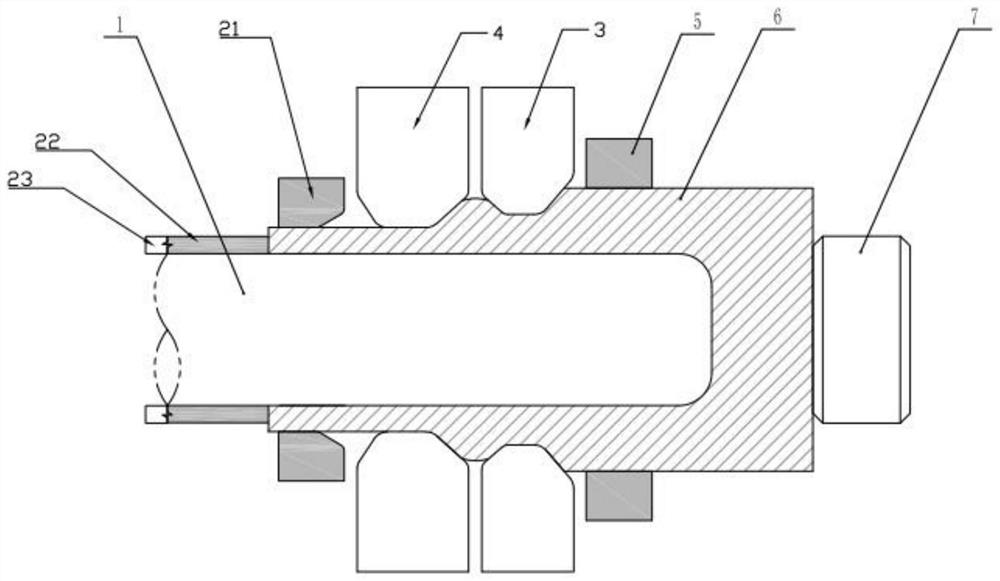

specific Embodiment approach 1

[0109] step one:

[0110] Select AerMet100 ultra-high-strength steel (23Co14Ni12Cr3MoE) cylindrical preform 6 with an outer diameter of 28mm and a height of 40mm, and prepare blind hole parts with an outer diameter of 28mm, an inner diameter of 12mm, a length of 46mm, and a hole depth of 30mm by hot extrusion forming equipment as preform 6 .

[0111] Step 2:

[0112] The axial thickness of the first group of hammer heads 3 is 14mm, the inclination of the first inlet flared conical surface 31 is 20°, the length of the radial loading working surface S is 4mm, the radius of the first transition fillet 33 is 20mm, and the first outlet flare The inclination of the mouth cone surface 32 is 60°; the overall thickness of the second group of hammer heads 4 is 14mm, the inclination of the second inlet flaring cone surface 41 is 60°, the length of the radial loading working surface S is 5mm, and the second transition fillet is 43 has a radius of 5mm. The radial depression amount of th...

specific Embodiment approach 2

[0125] step one:

[0126] Choose 30CrMnSiNi with an outer diameter of 26mm and a height of 40mm 2 A cylindrical preform 6, a blind hole with an outer diameter of 26 mm, an inner diameter of 12 mm, a length of 44 mm, and a hole depth of 28 mm is prepared as a preform 6 by hot extrusion forming equipment.

[0127] Step 2:

[0128] The axial thickness of the first group of hammer heads 3 is 14mm, the inclination of the first inlet flared conical surface 31 is 18°, the length of the radially loaded working surface S is 4mm, the radius of the first transition fillet 33 is 20mm, and the first outlet flare The inclination of the mouth cone surface 32 is 60°; the overall thickness of the second group of hammer heads 4 is 14mm, the inclination of the second inlet flaring cone surface 41 is 60°, the length of the radial loading working surface S is 5mm, and the second transition fillet is 43 has a radius of 5mm. The radial depression amount of the first group of hammer heads 3 is sel...

specific Embodiment approach 3

[0141] step one:

[0142] A 7075 aluminum alloy cylindrical preform 6 with an outer diameter of 24 mm and a height of 40 mm is selected, and a blind hole with an outer diameter of 24 mm, an inner diameter of 12 mm, a length of 46 mm, and a hole depth of 30 mm is prepared by hot extrusion forming equipment as the preform 6. .

[0143] Step 2:

[0144] The axial thickness of the first group of hammer heads 3 is 14mm, the inclination of the first inlet flared conical surface 31 is 16°, the length of the radial loading working surface S is 4mm, the radius of the first transition fillet 33 is 20mm, and the first outlet flare The inclination of the mouth cone surface 32 is 60°, and the radius of the first transition fillet 33 with the radial loading working surface S is 1.5mm; the overall thickness of the second group of hammer heads 4 is 14mm, and the second inlet flared cone surface 41 is inclined The angle is 60°, the length of the radially loaded working surface S is 5mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com