Preparation method and application of iron atom loaded graphene-based nano material

A graphene-based, nanomaterial technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low loading, complex preparation methods, and restrictions on commercial applications, and achieve high Effects of active site density, high activity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

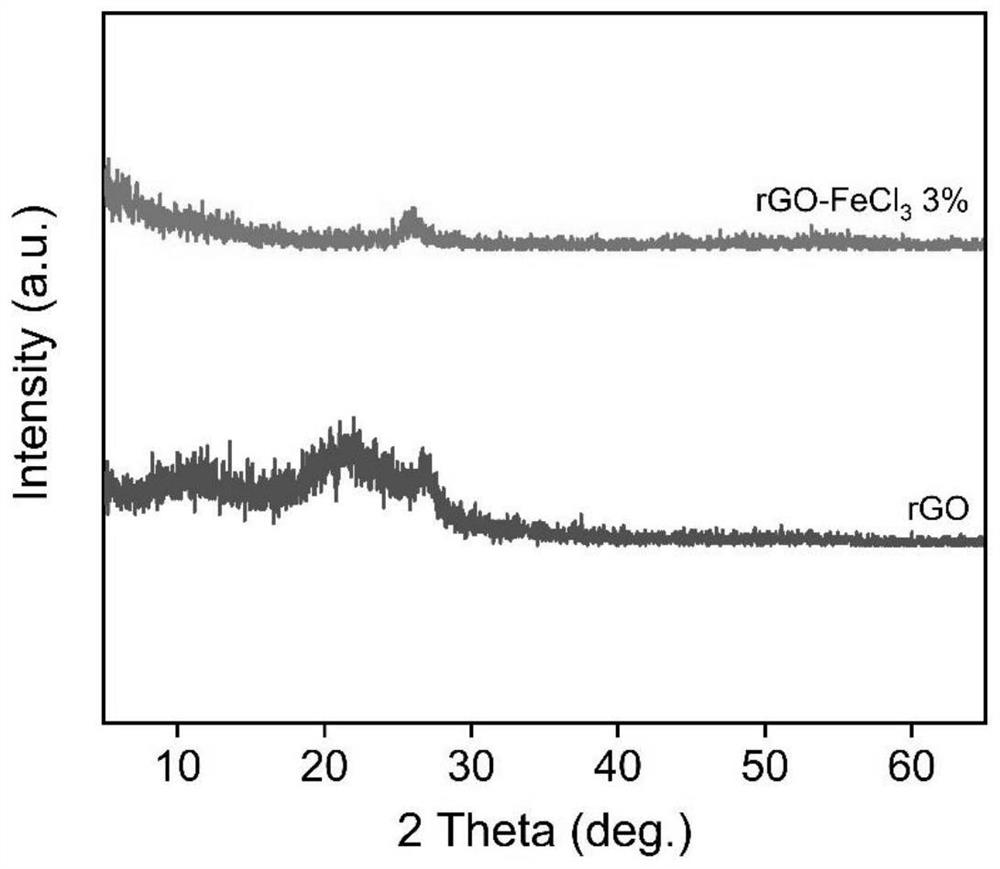

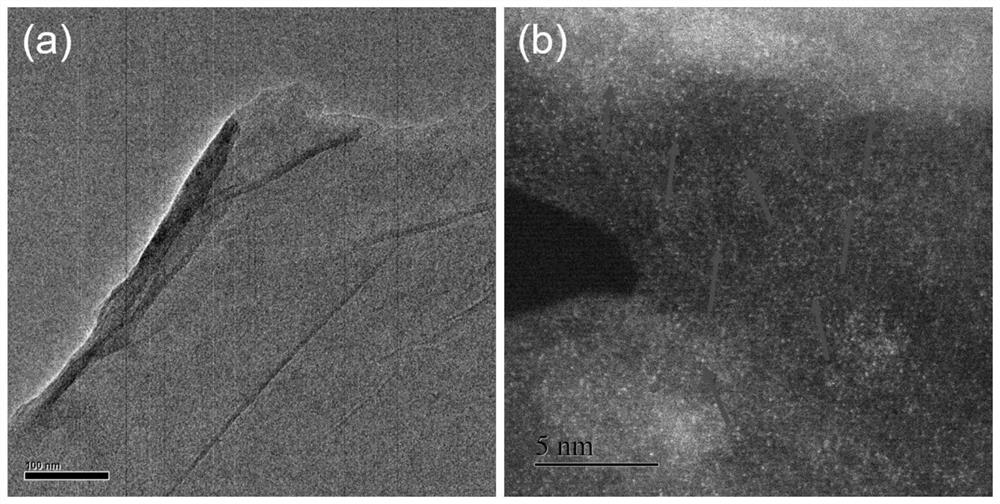

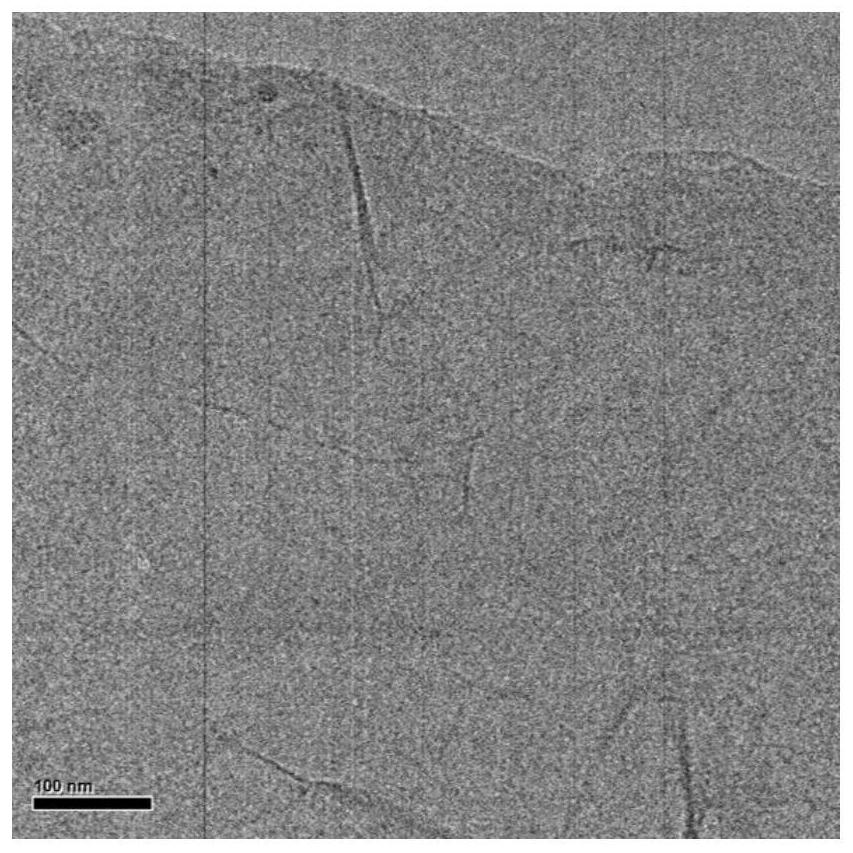

[0023] The technical solution of the present invention is a preparation method of iron atom-loaded graphene-based nanomaterials, comprising the following steps:

[0024] Step 1: Take 50-100 mg of anhydrous ferric chloride into a 25 ml volumetric flask, add tetrahydrofuran to dissolve, and make a 3 mg / ml ferric chloride solution;

[0025] Step 2: Take 10-20 mg of graphene oxide into a 25 ml volumetric flask, add tetrahydrofuran to dissolve, add 126 μL of step 1 to form a ferric chloride solution with a concentration of 3 mg / ml;

[0026] Step 3: Stir the mixture in step 2 on a magnetic stirrer for 12 hours until the solvent tetrahydrofuran is completely volatilized and a solid mixture is formed;

[0027] Step 4: Grind the solid mixture obtained in step 3 into powder and put it into a calcining vessel, place the calcining vessel in a high-temperature furnace for calcining, raise the temperature from room temperature 25°C to 400°C at a rate of 1°C / min and keep it warm for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com