5xxx series aluminum alloy melt purifying agent and preparation method thereof

A purifying agent, aluminum alloy technology, applied in the field of aluminum alloy processing, can solve the problems of damage to melt cleanliness, large solubility gap, narrow application range, etc., to achieve the effect of improving efficiency and effect, convenient storage, and increasing operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In terms of mass percentage, the composition of the cesium iodate-containing aluminum-based composite cleaning agent is: 5.1% of analytically pure cesium iodate and 94.9% of pure aluminum.

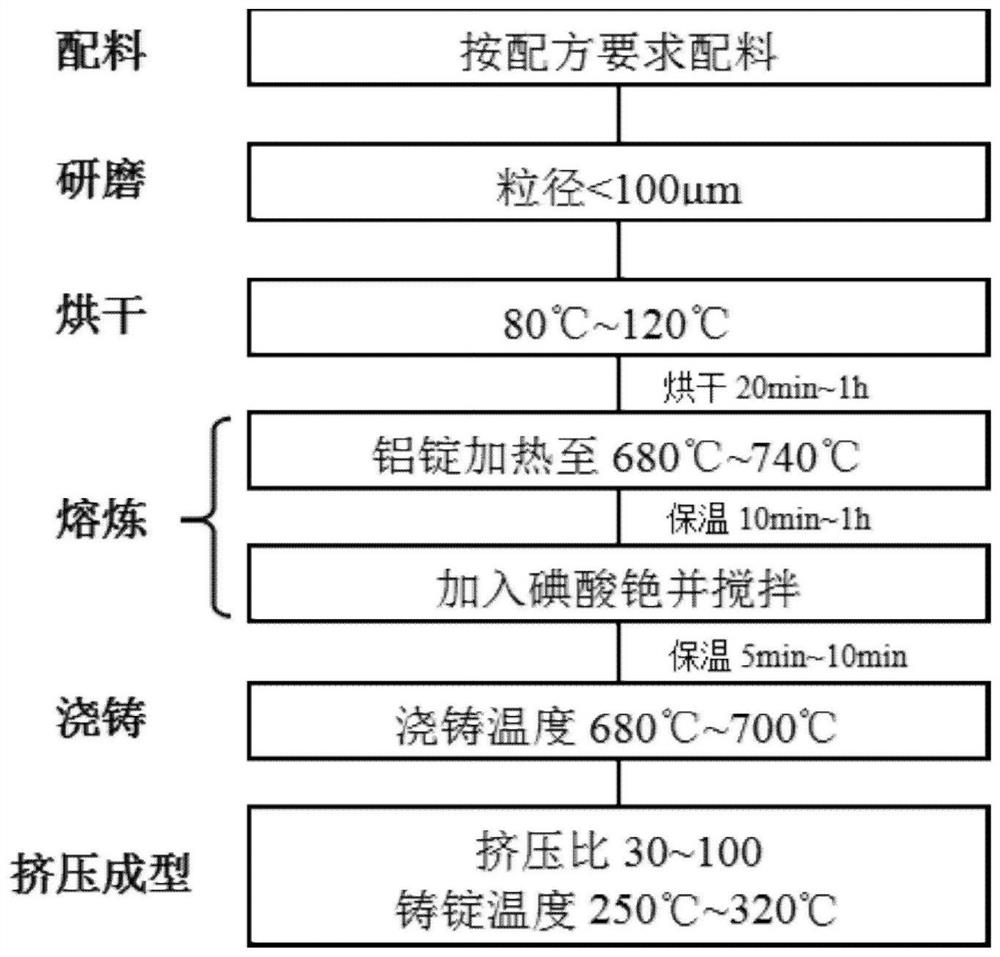

[0040] Weigh 949g of pure aluminum ingot, analyze 51g of pure cesium iodate, put it into an oven for drying, the drying temperature is 80°C, and the drying time is 30 minutes, and the above-mentioned weighed cesium iodate is ground into a particle size smaller than 100μm uniform powder and wrap it with aluminum foil. After adding pure aluminum aluminum ingots into the graphite crucible, put the crucible into a heating furnace and heat it to 690°C. The heating time is 2 hours, and then keep it warm for 20 minutes. Wrap it with aluminum foil paper with pliers. Cesium iodate is clamped into the melt, stirred for 1 minute and then kept warm for 5 minutes, slag-casting, the casting temperature is 680°C, the size of the cast cylindrical ingot is φ60mm×height 100mm, and then the extrusion m...

Embodiment 2

[0042] In terms of mass percentage, the composition of the cesium iodate-containing aluminum-based composite purifying agent is: 6.3% of analytically pure cesium iodate and 93.7% of pure aluminum.

[0043] Weigh 63g of analytically pure cesium iodate, put it into a mortar and grind it to a powder with a particle size of less than 100μm, wrap it with aluminum foil, roll it into a ball, weigh 937g of pure aluminum ingot, mix the pure aluminum ingot with aluminum foil The cesium iodate powder wrapped in paper is dried in an oven at a drying temperature of 80°C for 30 minutes. After drying, put the above-mentioned weighed pure aluminum ingot into a graphite crucible and put the crucible into In the heating furnace, the heating time is 2h, the heating temperature is 700°C, heat it to 700°C and keep it warm for 15 minutes, then clamp the cesium iodate wrapped in aluminum foil into the melt with pliers, stir it for 30 seconds, keep it warm for 6 minutes, remove the slag and cast , th...

Embodiment 3

[0045] In terms of mass percentage, the composition of the cesium iodate-containing aluminum-based composite cleaning agent is: 8.5% of analytically pure cesium iodate and 91.5% of pure aluminum.

[0046] Weigh 915g of pure aluminum ingot, put it into an oven for drying, the drying temperature is 90°C, and the drying time is 30 minutes. After drying to remove moisture, put it into a graphite crucible, and put the graphite crucible into a heating furnace for heating. The heating time is 2h, heat at 740°C for 10 minutes, weigh 85g of cesium iodate, grind it into powder with a mortar, the particle size is less than 100μm, then wrap it with aluminum foil to form a ball, and then put it in an oven for drying at a temperature of 90 ℃, drying for 30 minutes, then slowly clamp it into the molten pure aluminum with pliers, stir for 1 minute, then hold the temperature for 8 minutes and then cast the slag. The casting temperature is 700 ℃, and the size of the cast cylindrical ingot is φ6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com