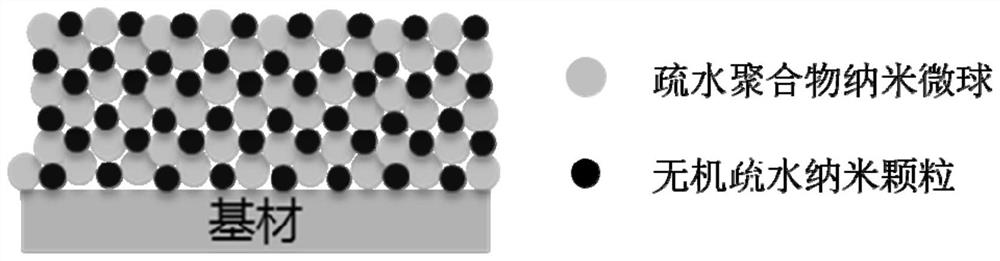

Super-hydrophobic coating as well as preparation method and application thereof

A technology of super-hydrophobic coating and hydrophobic nano-technology, which is applied in coatings, antifouling/underwater coatings, devices for coating liquid on the surface, etc., can solve the problem of low binding force, achieve good adhesion and durability, The preparation method is simple and the nanostructure is uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment provides a kind of preparation method of superhydrophobic coating, comprising:

[0049] (1) Preparation of coating:

[0050] In terms of mass fraction, the formula is as follows:

[0051] Heptadecafluorodecyltrimethoxysilane modified nano-silica with a particle size of about 200nm 1%; polystyrene microspheres with a particle size of about 200nm 5%; water 94%;

[0052] Among them, the nano-silica modified by heptadecafluorodecyltrimethoxysilane is prepared by the following method: 2 mL of silica sol with a particle size of about 200 nm is added to 40 mL of ethanol solution, and then 0.2% of ten Heptafluorodecyltrimethoxysilane was prepared by reacting for 10h.

[0053] Among them, polystyrene microspheres were prepared by adding 3 mL of styrene monomer into 200 mL of ethanol solution, heating to 70°C, adding 30 mL of potassium persulfate aqueous solution with a mass fraction of 0.1%, and reacting for 24 hours.

[0054] (2) Preparation of the coa...

Embodiment 2

[0057] The present embodiment provides a kind of preparation method of superhydrophobic coating, comprising:

[0058] (1) Preparation of coating:

[0059] In terms of mass fraction, the formula is as follows:

[0060] 1% of 3-(trimethoxysilyl) propyl methacrylate modified nano-silica with a particle diameter of about 200nm; 1% of organic silicon microspheres with a particle diameter of about 400nm; and 98% of ethanol.

[0061] Among them, methacrylate-3-(trimethoxysilyl)propyl ester modified nano-silica is prepared by the following method: add 2mL of silica sol with a particle size of about 200nm into 80mL of ethanol solution, and then add 3-(trimethoxysilyl)propyl methacrylate with a mass fraction of 1% was prepared by reacting for 18 hours.

[0062] Among them, organosilicon microspheres with a particle size of about 400 nm were purchased from Momentive, and the model was Tospearl 120.

[0063] (2) Preparation of coating: dip-coat the coating prepared in step (1) onto the...

Embodiment 3

[0065] The present embodiment provides a kind of preparation method of superhydrophobic coating, comprising:

[0066] (1) Preparation of coating:

[0067] In terms of mass fraction, the formula is as follows:

[0068] 5% of nano aluminum oxide modified by heptadecafluorodecyltrimethoxysilane with a particle diameter of about 400nm; 1% of polymethyl methacrylate microspheres with a particle diameter of about 800nm; and 94% of ethanol.

[0069] Wherein, heptadecafluorodecyltrimethoxysilane modified nano-alumina is prepared by the following method: add 2mL heptadecafluorodecyltrimethoxysilane dilution solution in 100mL ethanol solvent, add dropwise acid aqueous solution to pH The value is 3 to 4, hydrolyzed at room temperature for 1 hour, adding 2g of 400nm nano-aluminum oxide into the solution, heating it in a water bath to 80°C, reacting for a certain period of time, filtering, washing with toluene, and vacuum drying at 60°C for 24 hours.

[0070] Wherein, the polymethyl meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com