Iron-carbon filler containing nano treatment unit and preparation method thereof

A technology of iron-carbon filler and treatment unit, which is applied in the direction of metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of limitation, low current density in the sewage treatment process, and limited improvement of sewage treatment efficiency. , to achieve the effects of reducing toxicity, good effluent quality, simple preparation process and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

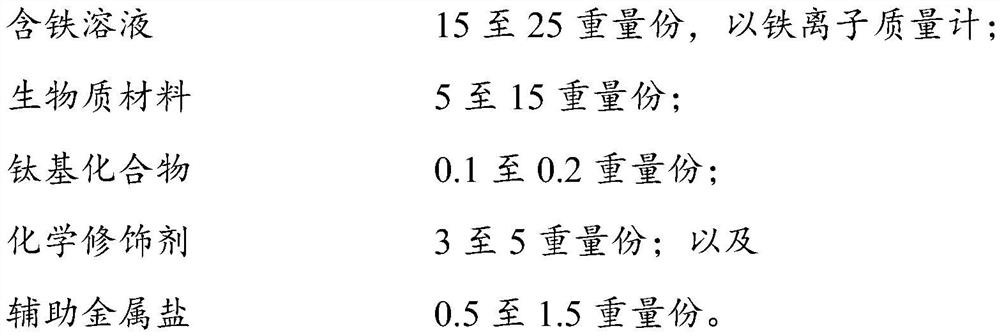

[0043] Preparation of iron carbon filler I

[0044] Step 1, 20 parts by weight of high-concentration iron-containing solution (iron ion concentration is 25000ppm), 10 parts by weight of lignin, 3 parts by weight of hydrogen peroxide and 1 part by weight of cobalt chloride are mixed, and then heated at a temperature of 60°C Fully carry out aeration reaction under 2 hours;

[0045] Step 2, adjust the pH to 3.0, then put in 0.1 parts by weight of titanic acid, and continue the reaction for 2 hours;

[0046] Step 3, after standing and settling for 6 hours, obtain a solid mixture through solid-liquid separation;

[0047] Step 4, the obtained solid mixture was dried at 65° C. for 12 hours, and then pulverized into 325-mesh particles by sieving;

[0048] Step 5, the particles obtained in step 4 are placed in a muffle furnace, baked at 180°C for 30 minutes under a nitrogen atmosphere to remove residual moisture, and then reacted in vacuum at 700°C for 2 hours; and

[0049] In ste...

Embodiment 2

[0056] Preparation of Fe-Carbon Filler II

[0057] Step 1, 18 parts by weight of high-concentration iron-containing solution (iron ion concentration is 25000ppm), 12 parts by weight of lignin, 4 parts by weight of hydrogen peroxide and 1 part by weight of cobalt chloride are mixed, and then heated at a temperature of 60 ° C. Fully carry out aeration reaction under 2 hours;

[0058] In step 2, adjust the pH to 3.0, then add 0.15 parts by weight of titanic acid, and continue the reaction for 2 hours;

[0059] Step 3, after standing and settling for 6 hours, obtain a solid mixture through solid-liquid separation;

[0060] Step 4, the obtained solid mixture was dried at 55° C. for 12 hours, and then pulverized into 300-mesh granules by sieving;

[0061] Step 5, the particles obtained in step 4 are placed in a muffle furnace, baked at 200°C under a nitrogen atmosphere for 30 minutes to remove residual moisture, and then reacted in vacuum at 800°C for 2 hours; and

[0062] Step...

Embodiment 3

[0069] Preparation of Fe-Carbon Filler III

[0070] Step 1, 20 parts by weight of high-concentration iron-containing solution (iron ion concentration is 30000ppm), 10 parts by weight of lignin, 5 parts by weight of hydrogen peroxide and 1 part by weight of nickel chloride are mixed, and then heated at a temperature of 50 ° C fully carry out the aeration reaction for 3 hours;

[0071] In step 2, adjust the pH to 3.0, then add 0.2 parts by weight of titanic acid, and continue the reaction for 2 hours;

[0072] Step 3, after standing and settling for 6 hours, obtain a solid mixture through solid-liquid separation;

[0073] Step 4, the obtained solid mixture was dried at 60° C. for 12 hours, and then crushed into 200-mesh granules by sieving;

[0074] Step 5, the particles obtained in step 4 are placed in a muffle furnace, baked at 200°C for 30 minutes under a nitrogen atmosphere to remove residual moisture, and then reacted in vacuum at 750°C for 2 hours; and

[0075] Step 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com