Multifunctional suspension plate for suspended ceiling and suspended ceiling assembly

A hanging board, multi-functional technology, applied in the direction of ceiling, building components, fire prevention, etc., can solve the problems of single function and low practicability of hanging decorative boards, and achieve the effect of reducing the overall weight, reducing the growth of microorganisms, and reducing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

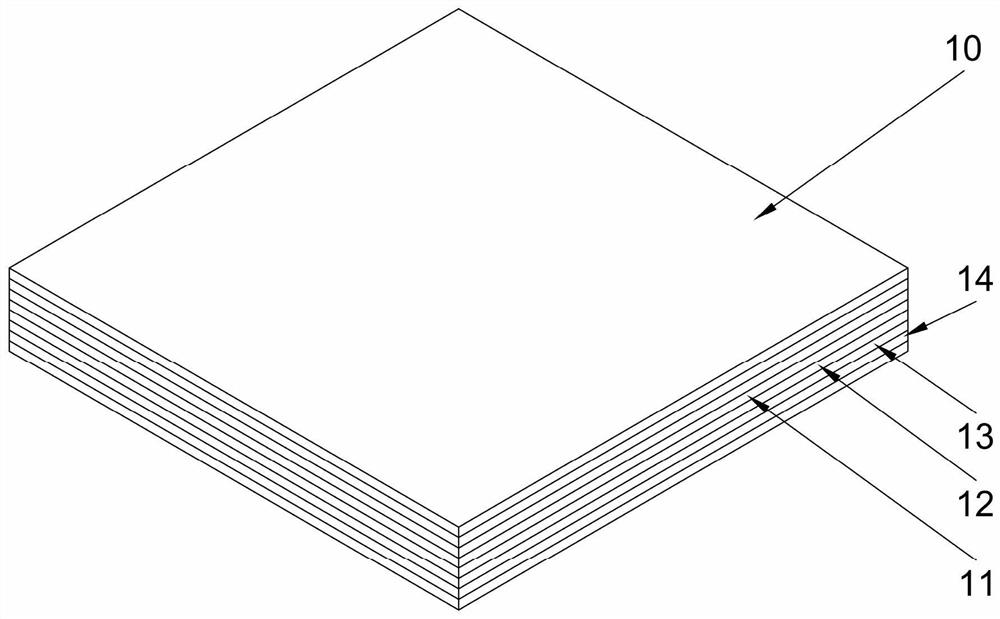

[0070] The preparation of the composite damping pad 13 is achievable by those skilled in the art and will not be described further here.

[0071] Further, the flame retardant and fireproof plastic core material 12 of the present invention includes the following raw materials in parts by weight:

[0072] 70-80 parts of ethylene-vinyl acetate copolymer;

[0073] 30-40 parts of metallocene linear low-density polyethylene;

[0074] 10-20 parts of maleic anhydride grafted polyethylene;

[0075] 20-50 parts of organophosphorus nitrogen flame retardant;

[0076] 30-40 parts of microencapsulated ammonium polyphosphate;

[0077] 20-25 parts of zinc borate;

[0078] 20-25 parts of aluminum hydroxide;

[0079] 8 to 12 parts of additives;

[0080] The granules of flame-retardant and fire-resistant plastic core material 12 are obtained by the following method: Weigh each raw material according to the proportion, put it into a mixer, and mix it at 110°C to 120°C for 15 minutes; then, ...

example 1

[0086] The flame retardant and fireproof plastic core material 12 of the present invention comprises the following raw materials in parts by weight:

[0087] 70 parts of ethylene-vinyl acetate copolymers;

[0088] 30 parts of metallocene linear low density polyethylene;

[0089] 10 parts of maleic anhydride grafted polyethylene;

[0090] 20 parts of organophosphorus nitrogen flame retardant;

[0091] 30 parts of microencapsulated ammonium polyphosphate;

[0092] 20 parts of zinc borate;

[0093] 20 parts of aluminum hydroxide;

[0094] 8 parts of auxiliary agent;

[0095] The granules of flame-retardant and fire-resistant plastic core material 12 are obtained by the following method: Weigh each raw material according to the proportion, put it into the mixer, and mix it at 110°C for 15 minutes; then, put the mixed raw material in banburying Mixing in a machine for 20 minutes, with a discharge temperature of 130°C; then put the raw material after banburying in a screw extr...

example 2

[0098] The flame retardant and fireproof plastic core material 12 of the present invention comprises the following raw materials in parts by weight:

[0099] 75 parts of ethylene-vinyl acetate copolymers;

[0100] 35 parts of metallocene linear low density polyethylene;

[0101] 15 parts of maleic anhydride grafted polyethylene;

[0102] 35 parts of organophosphorus nitrogen flame retardants;

[0103] 35 parts of microencapsulated ammonium polyphosphate;

[0104] 22 parts of zinc borate;

[0105] 22 parts of aluminum hydroxide;

[0106] 10 parts of auxiliary agent;

[0107] The granules of flame-retardant and fire-resistant plastic core material 12 are obtained by the following method: Weigh each raw material according to the proportion, put it into a mixer, and mix it at 115°C for 15 minutes; then, put the mixed raw material in banburying Mixing in a machine for 20 minutes, with a discharge temperature of 130°C; then put the raw material after banburying in a screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com