Alloy steel powder for laser additive manufacturing of composite high-speed rail brake disc and manufacturing method

A laser additive and alloy steel powder technology, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement, can solve the problems of low service life of brake discs, achieve good wear resistance, good comprehensive performance, and Excellent toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

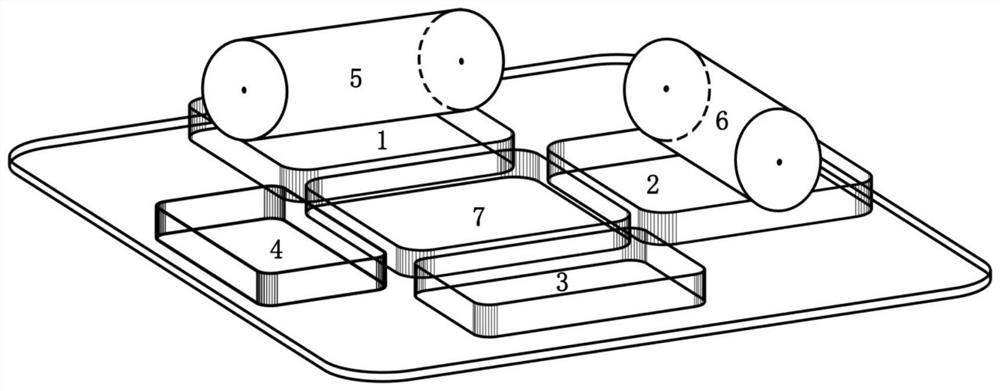

Method used

Image

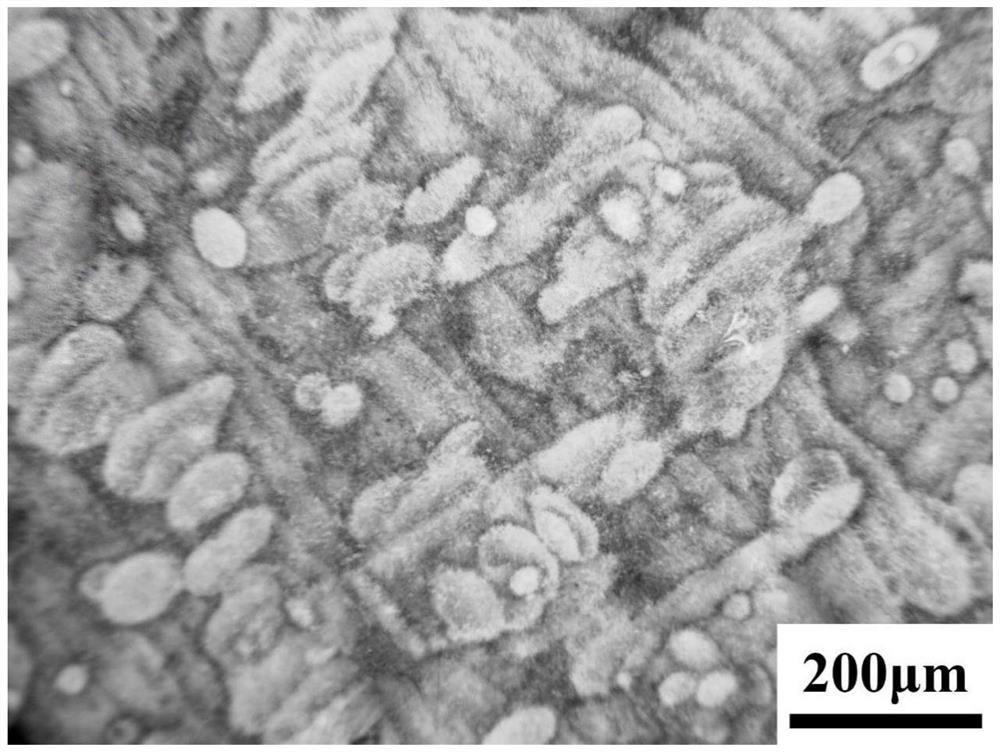

Examples

Embodiment 1

[0050] The mass percentage of 24CrNiMo low alloy steel powder is C: 0.20%, Cr: 1.04%, Ni: 0.96%, Si: 0.50%, Mo: 0.45%, Mn: 1.02%, O: 0.018%, and the rest is Fe;

[0051] The mass percentage of corrosion-resistant stainless steel powder is C: 0.16%, Cr: 16.50%, Ni: 4.70%, Si: 1.15%, Mo: 0.91%, Mn: 0.50%, B: 1.14%, Ti: 1.50% , Re: 0.50%, the rest is Fe;

[0052] The particle size of the 24CrNiMo low-alloy steel powder and the corrosion-resistant stainless steel powder is 28-45 μm.

[0053] A method for manufacturing composite high-speed rail brake disc alloy steel using the above-mentioned laser additive manufacturing alloy steel powder for composite high-speed rail brake discs, the method steps are as follows:

[0054] 1) Substrate pretreatment, austenitic stainless steel is used as the substrate, and the surface of the substrate to be melted and deposited is treated with 100 # and 200 # SiC metallographic sandpaper is polished flat, with a parallelism of 0.01mm, and then sa...

Embodiment 2

[0069] The mass percentage of 24CrNiMo low alloy steel powder is C: 0.25%, Cr: 0.98%, Ni: 1.02%, Si: 0.37%, Mo: 0.54%, Mn: 0.90%, O: 0.018%, and the rest is Fe;

[0070] The mass percentage of corrosion-resistant stainless steel powder is C: 0.18%, Cr: 15.00%, Ni: 10.70%, Si: 1.04%, Mo: 1.50%, Mn: 0.45%, B: 1.25%, Ti: 0.50% , Re: 1.80%, the rest is Fe;

[0071] The particle size of the 24CrNiMo low-alloy steel powder and the corrosion-resistant stainless steel powder is 28-45 μm.

[0072] A method for manufacturing composite high-speed rail brake disc alloy steel using the above-mentioned laser additive manufacturing alloy steel powder for composite high-speed rail brake discs, the method steps are as follows:

[0073] 1) Substrate pretreatment, austenitic stainless steel is used as the substrate, and the surface of the substrate to be melted and deposited is treated with 100 # and 200 # SiC metallographic sandpaper is polished flat, with a parallelism of 0.009mm, and then ...

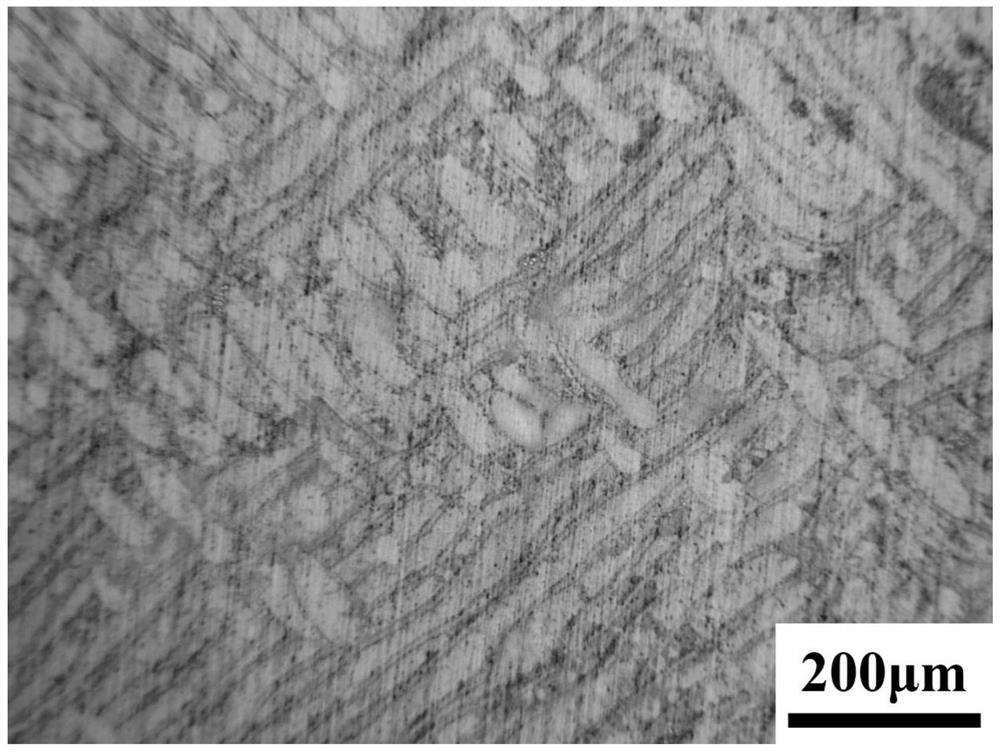

Embodiment 3

[0083] The mass percentage of 24CrNiMo low alloy steel powder is C: 0.22%, Cr: 1.00%, Ni: 1.00%, Si: 0.43%, Mo: 0.49%, Mn: 0.96%, O: 0.018%, and the rest is Fe;

[0084] The mass percentage of corrosion-resistant stainless steel powder is C: 0.17%, Cr: 15.80%, Ni: 6.70%, Si: 1.09%, Mo: 0.99%, Mn: 0.47%, B: 1.19%, Ti: 0.90% , Re: 0.90%, the rest is Fe;

[0085] The particle size of the 24CrNiMo low-alloy steel powder and the corrosion-resistant stainless steel powder is 28-45 μm.

[0086] A method for manufacturing composite high-speed rail brake disc alloy steel using the above-mentioned laser additive manufacturing alloy steel powder for composite high-speed rail brake discs, the method steps are as follows:

[0087] 1) Substrate pretreatment, austenitic stainless steel is used as the substrate, and the surface of the substrate to be melted and deposited is treated with 100 # and 200 # SiC metallographic sandpaper is polished flat, with a parallelism of 0.005mm, and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com