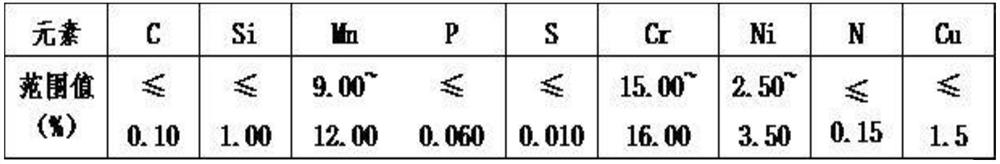

Production process of nickel-saving high-strength austenitic stainless steel

A technology of austenitic stainless steel and production technology, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., and can solve the problems of high material hardness, high nickel content, and increased production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

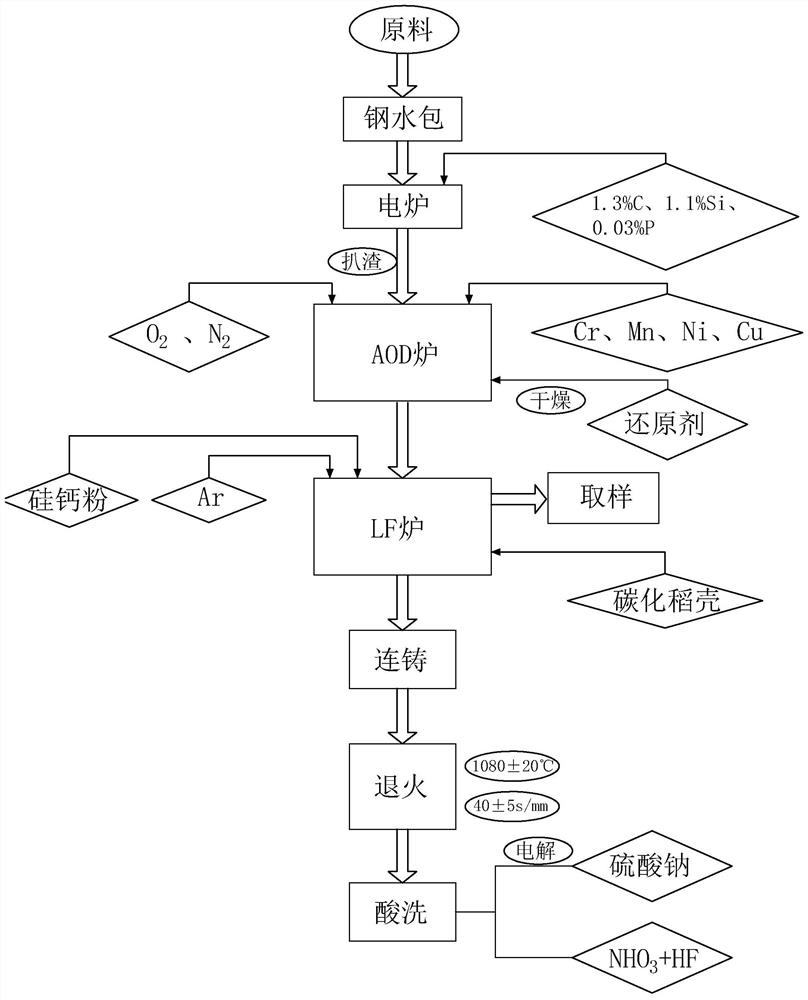

[0043] Such as figure 1 The production process of nickel-saving high-strength austenitic stainless steel shown in Figure x includes the following procedures and steps:

[0044] 1) Clean up the residue in the ladle and heat the ladle to 850°C;

[0045] 2) Electric Furnace Melting

[0046] 2.1) The amount of C in the electric furnace is 1.3%, the amount of Si is 1.1%, the content of P in the ingredients is 0.03%, and the binary basicity of the final slag is controlled at 1.5;

[0047] 2.2) The charge of the electric furnace is exhausted, and the tapping temperature is ≥1600°C;

[0048] 3) AOD refining

[0049] 3.1) Carry out the slag removal treatment on the molten steel, after the slag removal, the molten steel is blended into the AOD furnace, and the components are sampled and analyzed, and the temperature of the molten steel is measured;

[0050] 3.2) Decarburiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com