Preparation method of emulsion containing oleum fructus bruceae

A technology for guts and emulsions, applied in the field of medicine, can solve the problems of high proportion of large particles, high safety risks, inability to pass through sterilization-grade filters, etc., and achieve the effect of reducing the Ke value and improving the stability of the emulsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

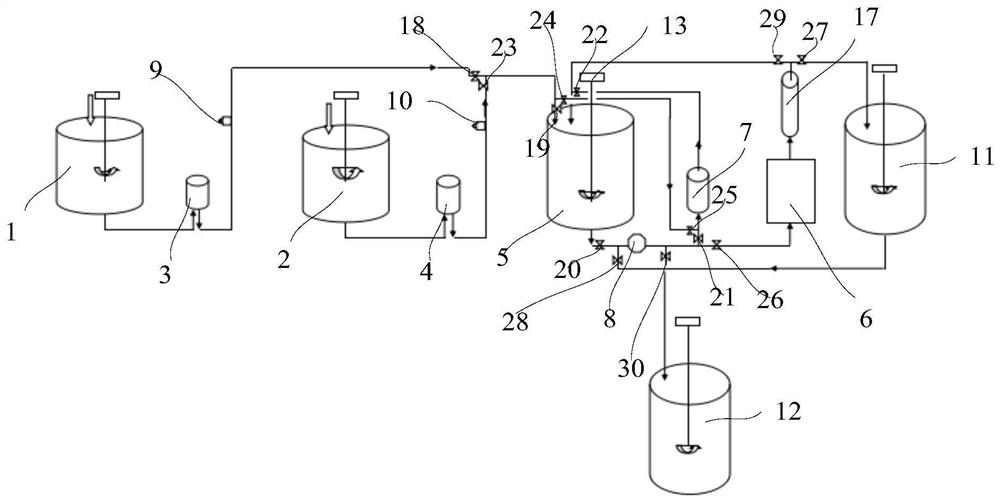

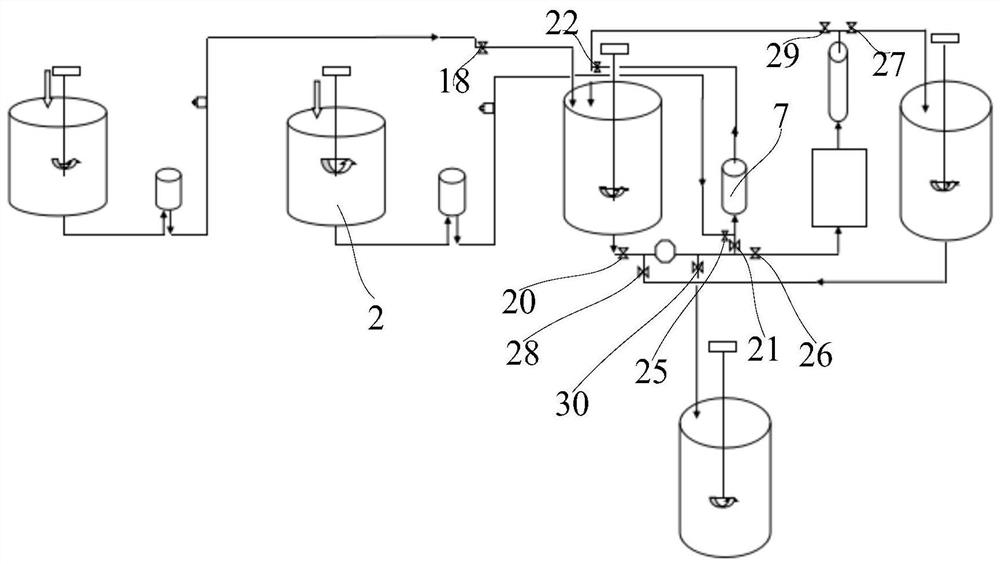

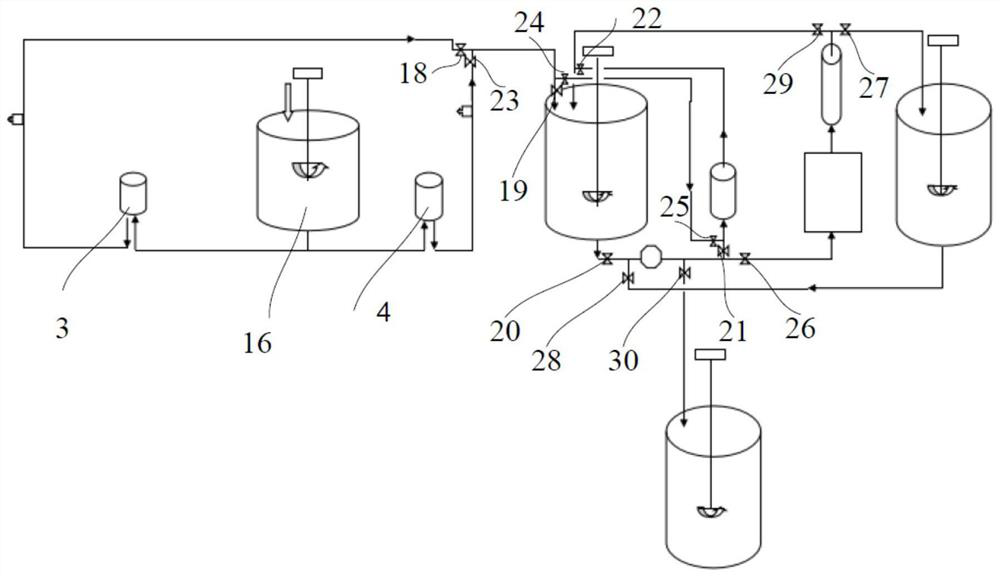

Method used

Image

Examples

Embodiment 1

[0099] Preparation of Brucea javanica oil emulsion (sample 1)

[0100] (1) Add 150 g of emulsifier soybean lecithin into the emulsification shear tank, add 3000 g of water for injection at 50 ° C, and carry out a 40-minute circulation emulsification shear to the emulsifier and water for injection by the emulsification shear tank and pipeline shear Cut to mix well. Then add 600g of 80°C glycerol aqueous solution (wherein glycerol and water for injection are uniformly mixed in a mass ratio of 1:1), and continue to carry out circulation emulsification and shearing of the gained mixture by the emulsification shear tank and the pipeline shearer for 3 times, the first time 20 minutes, 20 minutes the second time, 10 minutes the third time.

[0101] (2) Heat 1000ml of javanica javanica oil to 80°C, slowly add it to the pipeline shearer, and mix it with the mixture described in step (1) in the pipeline shearer to obtain an oil-water mixture , the oil-water mixture material is made to...

Embodiment 2

[0107] Preparation of Brucea javanica oil emulsion (sample 2)

[0108] (1) Put a total of 250g of emulsifier (egg yolk lecithin and poloxamer in a mass ratio of 1:1) into the emulsification shear tank, add 3750g of water for injection at 90°C, and shear through the emulsification shear tank and pipeline The emulsifier and water for injection were subjected to an 80-minute cycle of emulsification shear to make them fully mixed. Add the homogeneous mixed solution (wherein, the mass ratio of propylene glycol, mannitol and water for injection of 375g 100 ℃ of propylene glycol, mannitol and water for injection is 2: 1: 1.5), continue to pass through the emulsification shearing tank and pipeline shearing device The resulting mixture was subjected to cyclic emulsification shearing 4 times, 10 minutes each time.

[0109] (2) Heat 3000ml of javanica javanica oil to 100°C, slowly add it to the pipeline shear, and mix it with the mixture in step (1) in the pipeline shear to obtain an oi...

Embodiment 3

[0115] Preparation of Brucea javanica oil emulsion (sample 3)

[0116] (1) Add 120 g of the emulsifier soybean lecithin into the emulsification shear tank, add 600 g of water for injection at 40 ° C, and carry out a 10-minute circulation emulsification of the emulsifier and water for injection through the emulsification shear tank and pipeline shear Cut to mix well. Then add 1750ml of 50°C water for injection, and continue to carry out circulation emulsification and shearing of the resulting mixture twice, each time for 60 minutes, through the emulsification shear tank and the pipeline shearer.

[0117] (2) Heat 500ml of javanica javanica oil to 50°C, slowly add it into the pipeline cutter, and mix it with the mixture described in step (1) in the pipeline cutter to obtain an oil-water mixture , the oil-water mixture material is made to flow in the emulsified and sheared circulation channel, and the emulsified and sheared circulation is carried out by the pipeline shearer and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com