A kind of high weather resistance rubber coating and preparation method thereof

A rubber coating and rubber technology, applied in the rubber field, can solve the problems of changes in physical and mechanical properties, decline in mechanical properties, loss of elasticity of rubber, etc., and achieve the effects of simple operation, fast cross-linking speed and stable storage properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

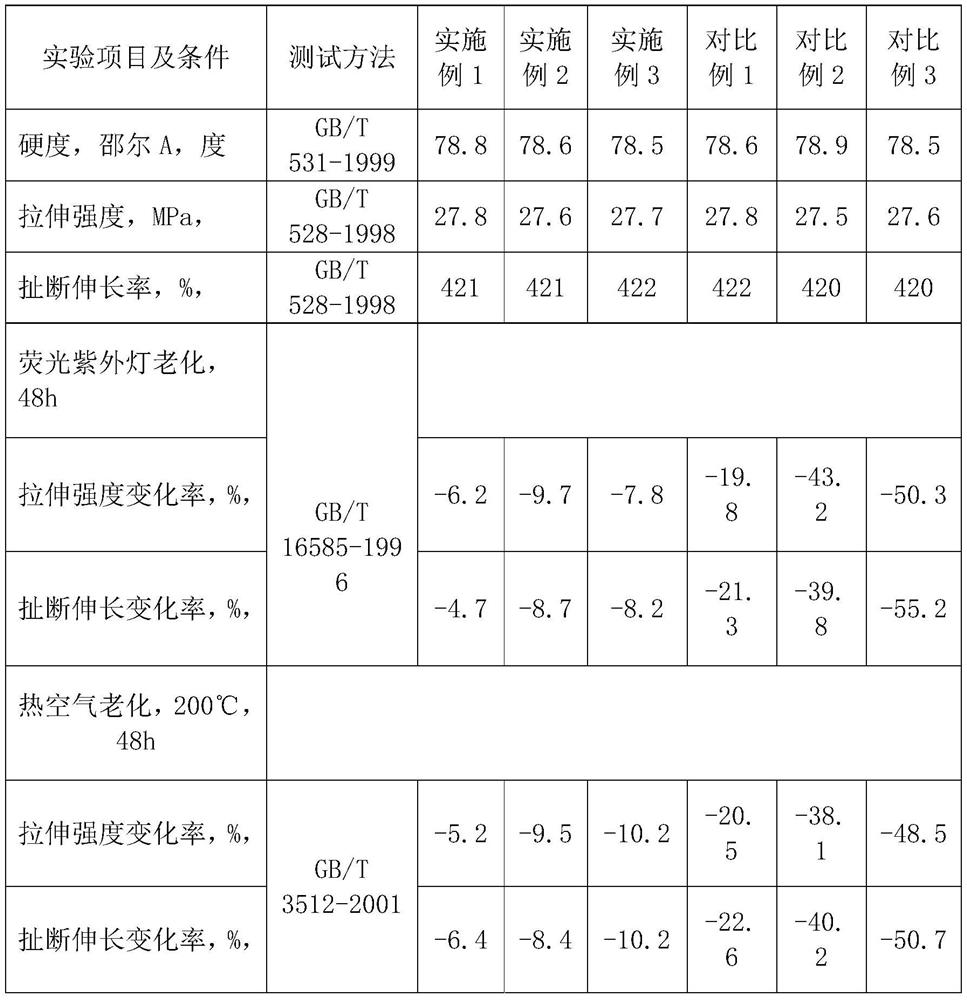

Examples

Embodiment 1

[0026] This embodiment provides a high weather resistance rubber coating, which is mainly prepared from the following raw materials in parts by weight: 17 parts of hydrogenated nitrile rubber, 75 parts of acetone, bis(7-oxabicyclo[4.1.0]3-heptylmethyl 1 part of adipate, 1 part of isophorone diisocyanate, 1 part of polyoxypropylene polyol, 1.4 parts of 1,6-hexamethylene diisocyanate trimer, 3 parts of surface-treated fumed silica, and other additives 0.6 parts; other additives include 0.1 parts of coupling agent silane coupling agent KH560, 0.1 parts of divinyltetramethyldisiloxane platinum complex, 0.1 parts of antioxidant 1010, 0.1 parts of anti-aging agent RD, 0.1 parts Anti-ultraviolet absorbent UV-351, 0.1 part of dibutyl phthalate.

[0027] A high-weather-resistant rubber coating provided in this embodiment is prepared by the following preparation method, which specifically includes the following steps:

[0028] Step 1, rubber solution preparation: add 17 parts of hydrog...

Embodiment 2

[0032]This embodiment provides a high weather-resistant rubber coating, which is mainly prepared from the following raw materials in parts by weight: 20 parts of polyacrylate rubber, 70 parts of methyl ethyl ketone, 2,3-epoxycyclopentylcyclopentane 1.5 parts of ether, 1.4 parts of hydrogenated phenylmethane diisocyanate, 1.5 parts of polycarbonate polyol, 1 part of isophorone diisocyanate trimer, 4 parts of surface-treated nano-silicon carbide, 0.6 parts of other additives; other additives Including 0.1 part of coupling agent silane coupling agent KH560, 0.1 part of triethylenediamine cyanate, 0.1 part of antioxidant 1076, 0.1 part of anti-aging agent RD, 0.1 part of anti-ultraviolet absorber UV-328, triphenyl phosphate 0.1 part.

[0033] A high-weather-resistant rubber coating provided in this embodiment is prepared by the following preparation method, which specifically includes the following steps:

[0034] Step 1, preparation of rubber solution: add 20 parts of polyacryla...

Embodiment 3

[0038] This embodiment provides a high weather-resistant rubber coating, which is mainly prepared from the following raw materials in parts by weight: 14 parts of nitrile rubber-polyvinyl chloride blend rubber, 72.4 parts of acetylacetone, 3,4-epoxy-6- 2 parts of cyclohexyl methyl ester, 2 parts of 1,6-hexamethylene diisocyanate, 2 parts of polycaprolactone polyol, 2 parts of 1,6-hexamethylene diisocyanate trimer, 5 parts of surface-treated nano-zirconia, other auxiliary 0.6 part of agent; other additives include 0.1 part of coupling agent silane coupling agent KH560, 0.1 part of DBU formate, 0.1 part of antioxidant 1035, 0.1 part of anti-aging agent 4010NA, 0.1 part of anti-ultraviolet absorber UV-326, 0.1 part of dibutyl phthalate.

[0039] A high-weather-resistant rubber coating provided in this embodiment is prepared by the following preparation method, which specifically includes the following steps:

[0040] Step 1, preparation of rubber solution: add 14 parts of nitril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com