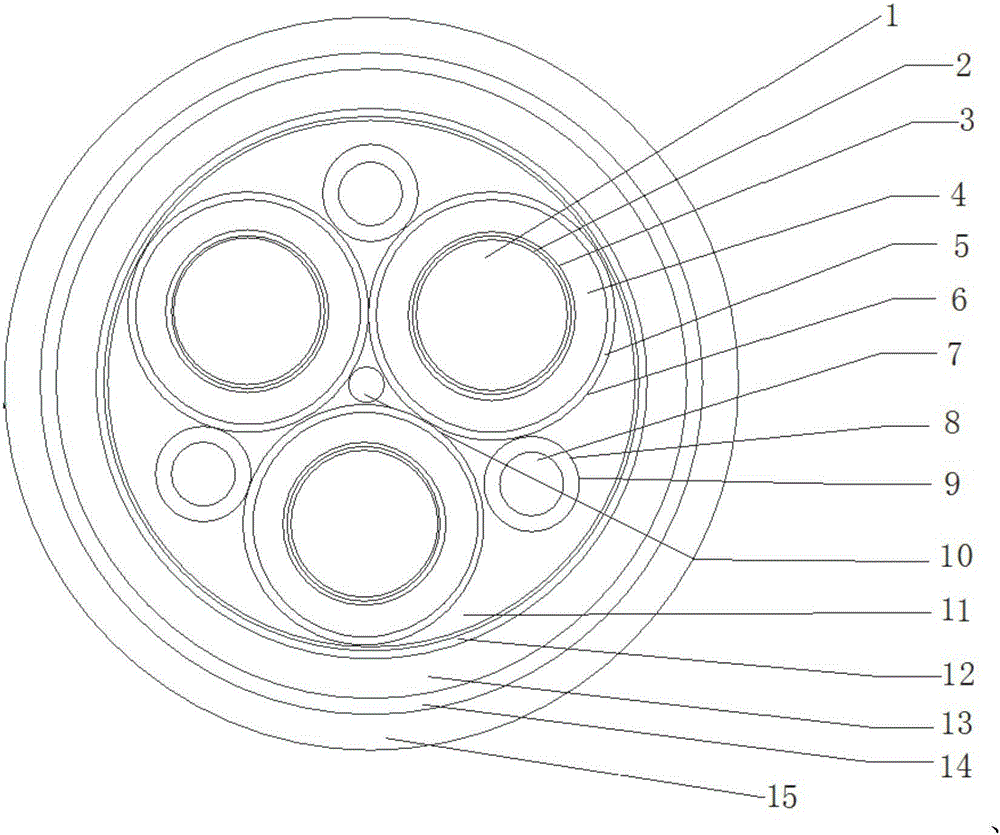

Wear-resistant, drag-resistant and low-temperature resistant flexible cable and fabrication method thereof

A flexible cable, low temperature resistant technology, applied in the field of power cables, can solve the problems of restricting the development technology level of the domestic equipment manufacturing industry, the reliability and stability of equipment supporting cables are not strong, and the procurement cycle is long. Symmetrical structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0180] In step 3):

[0181] The conductor shielding material is extruded at 36°C in the first zone, 45°C in the second zone, and 57°C in the third zone;

[0182] Extrusion of insulation material in the first zone 93°C, in the second zone 98°C, in the third zone 111°C;

[0183] Insulation and shielding material extrusion zone 1 is 35°C, zone 2 is 44°C, zone 3 is 58°C, zone 4 is 71°C;

[0184] The temperature zones of the machine head unit are: Zone 1 104°C, Zone 2 108°C, Zone 3 113°C;

[0185] In step 4):

[0186] The temperature distribution in each area of the fuselage is: 47°C in the first area, 75°C in the second area, and 93°C in the third area;

[0187] The temperature zones of the head unit are: Zone 1 82°C, Zone 2 86°C, Zone 3 93°C;

[0188] In step 6):

[0189] The temperature of each zone of the rubber extrusion machine body is: 80°C in the first zone, 55°C in the second zone, 60°C in the third zone, 66°C in the fourth zone, and 73°C in the fifth zone;

[0190...

example 2

[0195] In step 3):

[0196] The conductor shielding material is extruded at 30°C in the first zone, 40°C in the second zone, and 55°C in the third zone;

[0197] Extrusion of insulating material in the first zone 90°C, in the second zone 95°C, in the third zone 105°C;

[0198] Extrusion of insulating shielding material at 30°C in the first zone, 40°C in the second zone, 55°C in the third zone, and 60°C in the fourth zone;

[0199] The temperature zones of the head unit are: Zone 1 100°C, Zone 2 105°C, Zone 3 110°C;

[0200] In step 4):

[0201] The temperature distribution of each zone of the fuselage is: 40°C in the first zone, 70°C in the second zone, and 90°C in the third zone;

[0202] The temperature zones of the machine head unit are: zone 1 80°C, zone 2 85°C, zone 3 90°C;

[0203] In step 6):

[0204] The temperature of each zone of the rubber extrusion machine body is: 48°C in the first zone, 53°C in the second zone, 58°C in the third zone, 63°C in the fourth zone...

example 3

[0210] In step 3):

[0211] The conductor shielding material is extruded at 40°C in the first zone, 50°C in the second zone, and 60°C in the third zone;

[0212] Extrusion of insulation materials in the first zone 95°C, in the second zone 100°C, in the third zone 115°C;

[0213] Extrusion of insulating shielding material at 40°C in the first zone, 50°C in the second zone, 60°C in the third zone, and 75°C in the fourth zone;

[0214] The temperature zones of the head unit are: Zone 1 106°C, Zone 2 110°C, Zone 3 115°C;

[0215] In step 4):

[0216] The temperature distribution of each zone of the fuselage is: 50°C in the first zone, 80°C in the second zone, and 95°C in the third zone;

[0217] The temperature zones of the machine head unit are: Zone 1 85°C, Zone 2 88°C, Zone 3 95°C;

[0218] In step 6):

[0219] The temperature of each zone of the fuselage of the rubber extrusion machine is: 53°C in the first zone, 58°C in the second zone, 62°C in the third zone, 68°C in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com