A kind of manufacturing method of superfine fiber spunlace nonwoven filter material

A non-woven fabric and ultra-fine fiber technology, applied in the field of non-woven fabrics, can solve the problems of only filtration efficiency, poor product strength, large filtration resistance, etc., and achieve uniform electret distribution, stable electret effect, and comprehensive filtration efficiency improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

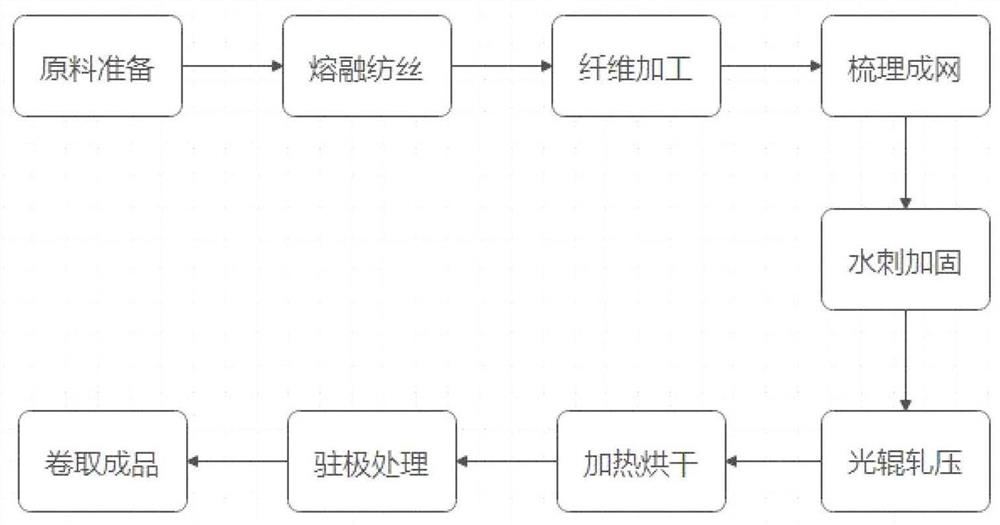

[0048] like figure 1 The manufacturing method of a superfine fiber spunlace nonwoven filter material shown, comprises the following steps:

[0049] (1) Preparation of raw materials: Two resin components, polypropylene (PP) and polyester (PET), are selected, and nano-tourmaline powders are added separately by means of atomization spraying using an ultrasonic sprayer. The mass percentage content of the nano tourmaline powder in each resin component is 0.4%. The particle size of nano-tourmaline powder is 200-450nm, among which, the PET resin needs to be dried before use, and dried in hot air at 170 ° C for 8 hours to reduce the moisture content from 0.4% to below 0.01%;

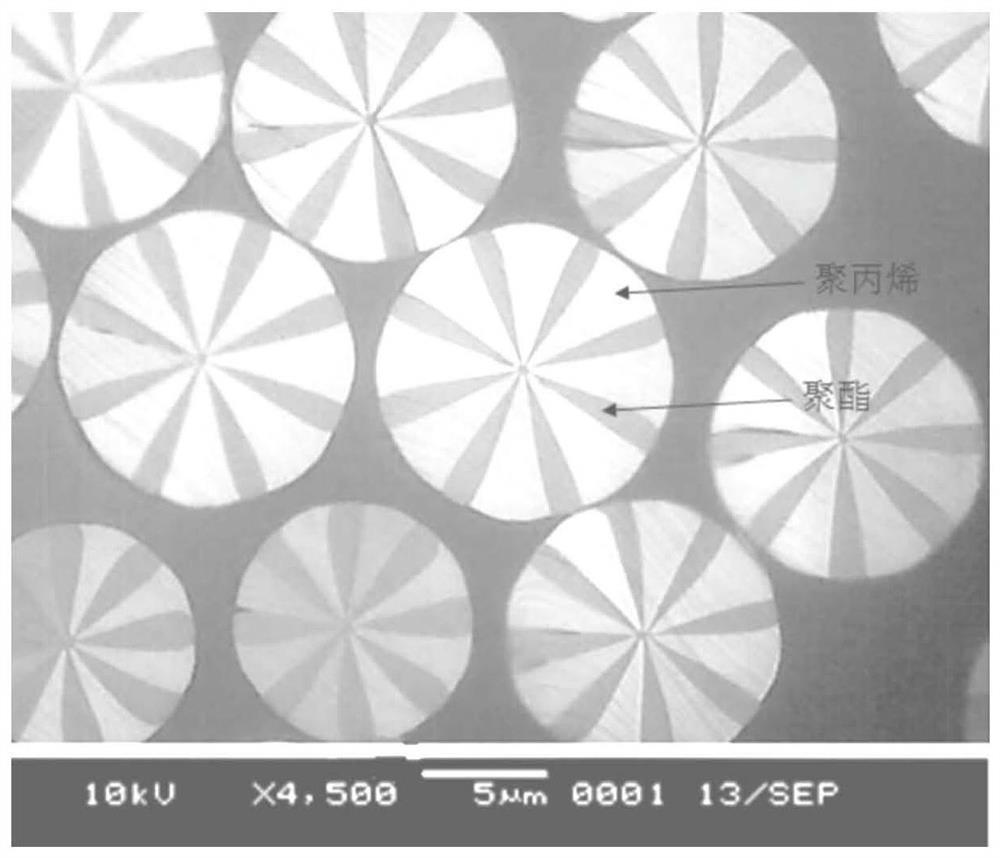

[0050] (2) Melt spinning: The above two components are respectively fed into two sets of melting components in the mass ratio of PP70% and PET30%, that is, they enter the screw extruder for heating, softening, melting and then feeding into the metering pump, and the two kinds of quantitative extrusion The poly...

Embodiment 2

[0060] The present embodiment is a method for manufacturing a superfine fiber spunlace nonwoven filter material, comprising the following steps:

[0061] (1) Preparation of raw materials: Two resin components, polypropylene (PP) and polyester (PET), are selected, and nano-tourmaline powders are added separately by means of atomization spraying using an ultrasonic sprayer. The particle size of the nano tourmaline powder is 300-400nm, and the mass percentage content of the nano tourmaline powder in each resin component is 0.4%. Among them, the PET resin needs to be dried before use, and dried under hot air at 170 ° C for 8 hours to reduce the moisture content from 0.4% to below 0.01%;

[0062] (2) Melt spinning: the above two components are respectively fed into two sets of melting components in the mass ratio of PP50% and PET50%, that is, they enter the screw extruder for heating, softening, melting and then feeding into the metering pump, and the two kinds of quantitative extr...

Embodiment 3

[0072] In this example, the 50gsm air filtration spunlace nonwoven fabric is manufactured, and the steps are the same as those in Example 1, except that in the process of carding into a web, the amount of loaded short fibers added is relatively small, and the spunlace pressure in the spunlace reinforcement is relatively small. Under the impact of six high-pressure water needles of 3Mpa, 6Mpa, 10Mpa, 12Mpa, 16Mpa and 13Mpa in turn, they are split into ultra-fine fibers and entangled with each other to form a wet spunlace non-woven fabric. The finished product has a gram weight of 50gsm. The atomization spraying process is: using the UAM4000L ultrasonic sprayer provided by Hangzhou Chifei Ultrasonic Equipment Co., Ltd., the nano tourmaline powder is atomized into uniform particles by ultrasonic high-frequency oscillation, and then sprayed out uniformly with the high-speed impact air jet. The fall is attached to the resin. The ultrasonic frequency is 50KHz, the air pressure is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com