Automobile part die-casting aluminum alloy smelting process

A technology for casting aluminum alloys and auto parts, applied in the field of aluminum alloy smelting, can solve the problems of increasing production cost, poor treatment effect, complicated equipment and operation, etc., to reduce the difficulty of cracking, improve the purification effect and improve the removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

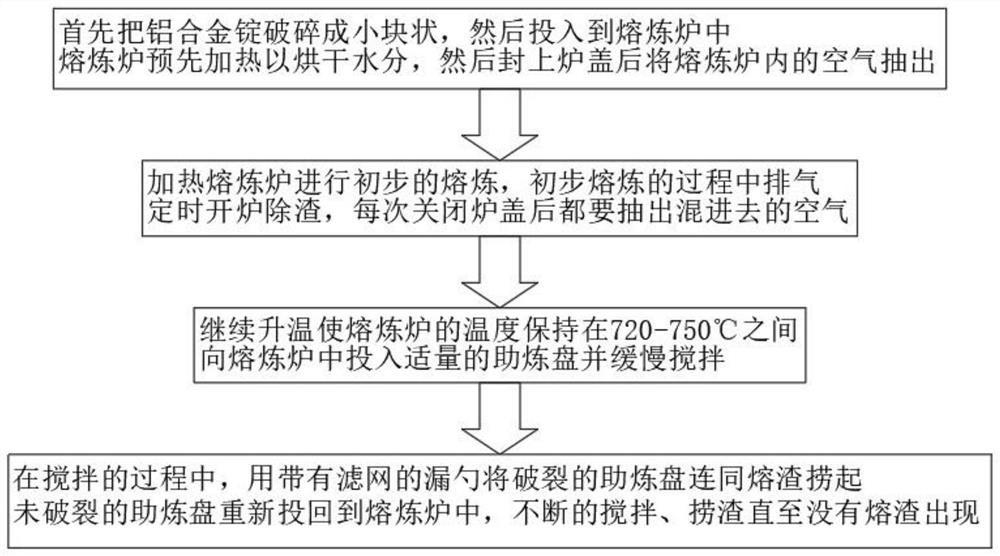

[0045] see Figure 1-4 , a die-casting aluminum alloy smelting process for auto parts, see figure 1 , including the following steps:

[0046] S1, first break the aluminum alloy ingot into small pieces, and then put it into the melting furnace, the melting furnace is preheated to dry the water, and then the air in the melting furnace is drawn out after sealing the furnace cover;

[0047] S2, heating the smelting furnace for preliminary smelting, exhausting during the preliminary smelting process, opening the furnace regularly to remove slag, and pumping out the mixed air after closing the furnace cover every time;

[0048] S3, continue to heat up to keep the temperature of the smelting furnace between 720-750°C, put an appropriate amount of auxiliary smelting pan into the smelting furnace and stir slowly;

[0049] S4. In the process of stirring, use a colander with a filter to pick up the broken auxiliary refining pan together with the slag, and put the unbroken auxiliary ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com