Single-component scale type epoxy zinc-rich anti-corrosive primer and preparation method thereof

An epoxy zinc-rich, anti-rust primer technology, applied in the direction of epoxy resin coatings, chemical instruments and methods, anti-corrosion coatings, etc., can solve the problems of poor flexibility of the paint film, difficult operation, slow drying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

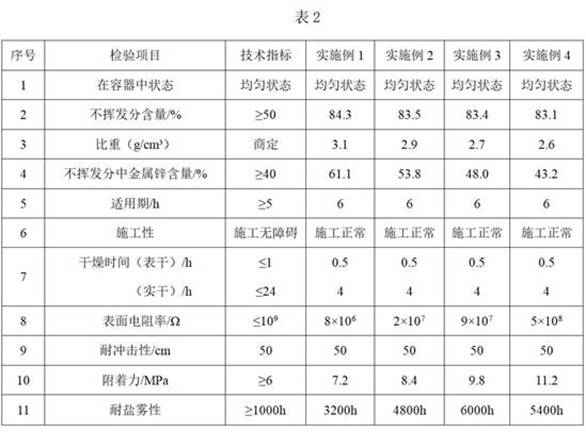

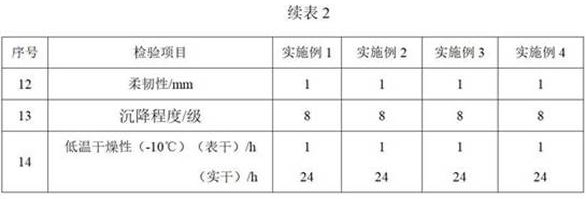

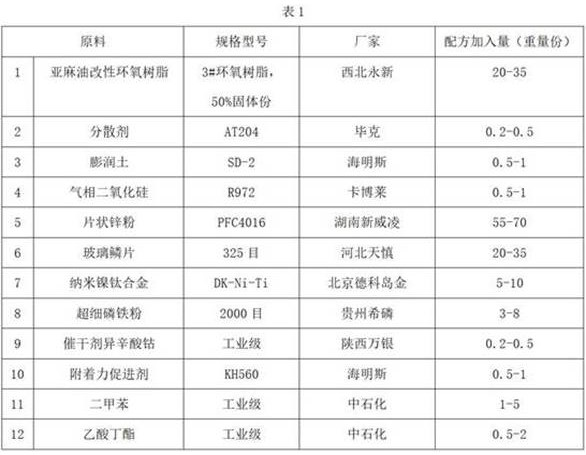

[0029] Embodiment 1, a kind of one-component flake type epoxy zinc-rich antirust primer is composed as follows:

[0030]Prepare raw materials according to the following parts by mass: 20 parts of linseed oil modified epoxy resin, 0.5 part of dispersant AT204, 1 part of bentonite SD-2, 0.5 part of fumed silica R972, 70 parts of flaky zinc powder, 20 parts of glass flakes , 5 parts of nano-nickel-titanium alloy, 3 parts of superfine ferrophosphorus powder, 0.2 part of cobalt isooctanoate as drier, 1 part of adhesion promoter KH560, 5 parts of xylene, 2 parts of butyl acetate;

[0031] Preparation:

[0032] A. At 300 rev / min, in a clean stirred tank, linseed oil modified epoxy resin, dispersant AT204, bentonite SD-2, fumed silica R972, flaky zinc powder, glass flakes, nano-nickel-titanium alloy , Superfine ferrophosphorus powder, stir evenly;

[0033] B. Increase the speed to 1200 rpm, disperse at high speed for 40 minutes, pay attention to the temperature of the slurry during ...

Embodiment 2

[0036] Embodiment 2, the composition of a kind of one-component flake type epoxy zinc-rich antirust primer is as follows: Prepare raw materials according to the following mass parts: 25 parts of linseed oil modified epoxy resin, 0.2 part of dispersant AT204, bentonite SD-2 0.5 parts, fumed silica R9720.8 parts, 65 parts of flaky zinc powder, 25 parts of glass flakes, 6 parts of nano-nickel-titanium alloy, 5 parts of superfine iron phosphorus powder, 0.3 parts of cobalt isooctanoate as drier, adhesion Accelerator KH560 0.8 parts, xylene 4 parts, butyl acetate 1.5 parts;

[0037] Preparation:

[0038] A. Under the rotation speed of 500 rpm, in a clean stirring tank, linseed oil modified epoxy resin, dispersant AT204, bentonite SD-2, fumed silica R972 parts, flaky zinc powder, glass flakes, nano-nickel titanium Alloy, superfine ferrophosphorus powder, stir evenly;

[0039] B. Increase the speed to 1100 rpm, disperse at high speed for 50 minutes, pay attention to the temperature...

Embodiment 3

[0042] Embodiment 3, the composition of a kind of one-component flake type epoxy zinc-rich antirust primer is as follows: Prepare raw materials according to the following mass parts: 30 parts of linseed oil modified epoxy resin, 0.2 part of dispersant AT204, bentonite SD-2 0.5 parts, fumed silica R9720.8 parts, 60 parts of flaky zinc powder, 30 parts of glass flakes, 8 parts of nano-nickel-titanium alloy, 5 parts of superfine iron phosphorus powder, 0.3 parts of cobalt isooctanoate as drier, adhesion Accelerator KH560 0.6 parts, xylene 2 parts, butyl acetate 1 part;

[0043] Preparation:

[0044] A. Under the rotation speed of 500 rpm, in a clean stirring tank, linseed oil modified epoxy resin, dispersant AT204, bentonite SD-2, fumed silica R972 parts, flaky zinc powder, glass flakes, nano-nickel titanium Alloy, superfine ferrophosphorus powder, stir evenly;

[0045] B. Increase the speed to 1100 rpm, disperse at high speed for 50 minutes, pay attention to the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com