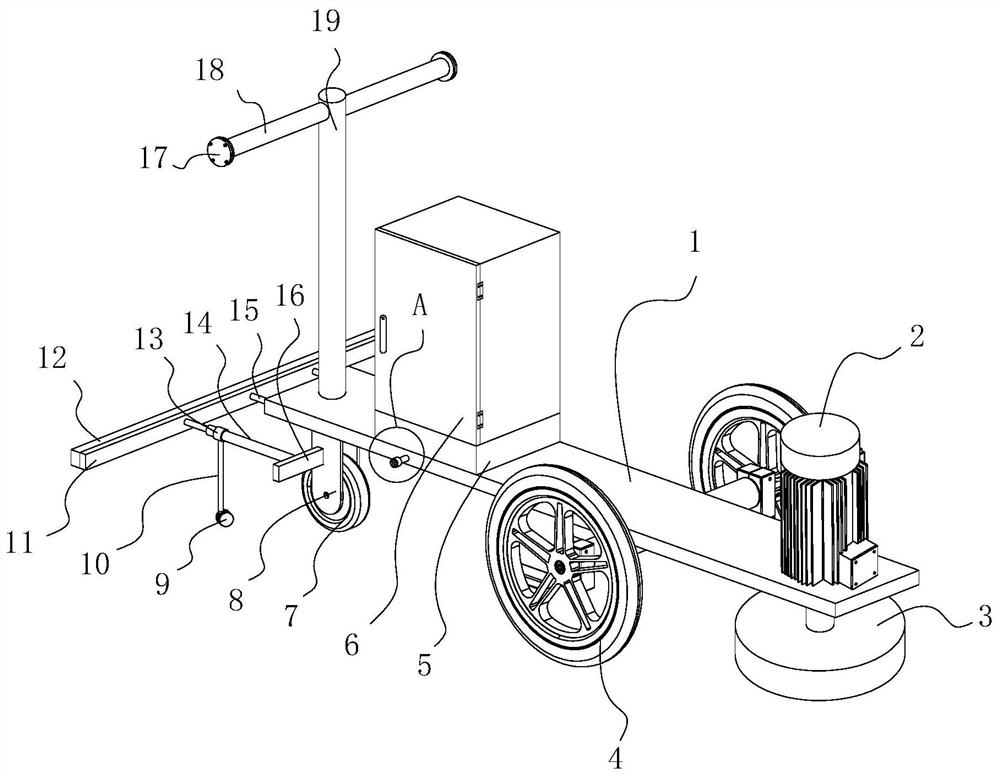

Ship deck rust removal device

A technology for ship decks and equipment, applied in the field of ship deck rust removal equipment, can solve the problems of difficult operation, insufficient stability, easy to swing left and right, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

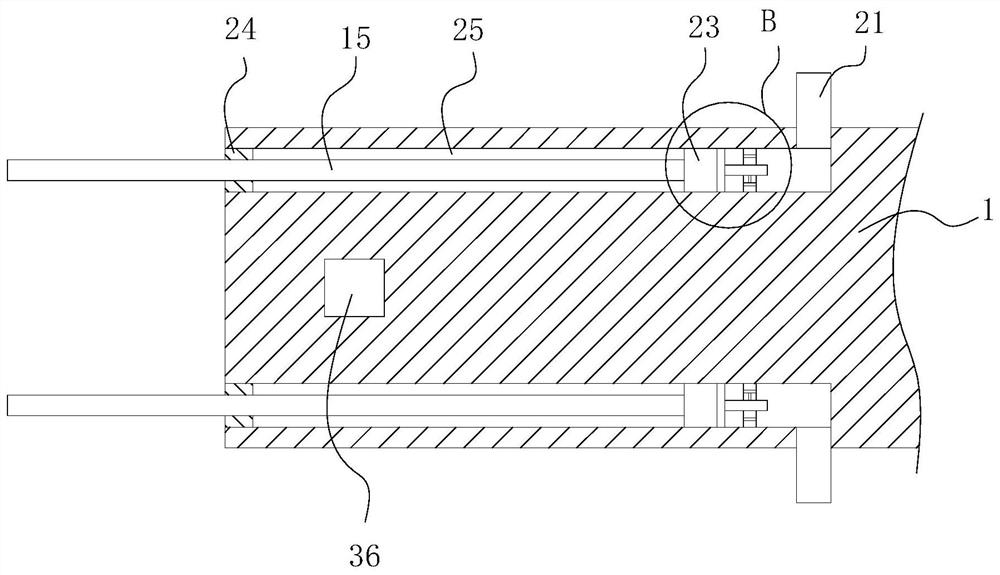

[0040] Specific implementation method: before the process of polishing the deck, the first electric push rod 14 is controlled to extend or shrink, and then the first electric push rod 14 drives the strip plate 11 to move, so that the distance between the strip plate 11 and the bottom plate 1 becomes larger Or shrink, during the grinding process, make the strip plate 11 contact with the personnel's legs, and then under the support limit of the personnel's legs, the end of the anti-bottom plate 1 installed with the grinding mechanism will swing to improve the stability of the structure and reduce the operation difficulty.

[0041] When the first electric push rod 14 is used to drive the strip plate 11 to move, the strip plate 11 drives the guide rod 15 to slide along the guide hole 25, thereby realizing the function of positioning and guiding and improving the stability of the structure. The guide rod 15 drives the rubber plug 23 When sliding in the guide hole 25, the air in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com