Battery cover sealing structure, manufacturing method thereof and battery

A manufacturing method and a technology of a bonding structure, which are applied in the battery cover sealing structure and its manufacturing method, and the field of batteries, can solve problems such as low sealing performance, achieve the effects of improving sealing performance, satisfying industrial production, and simple manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

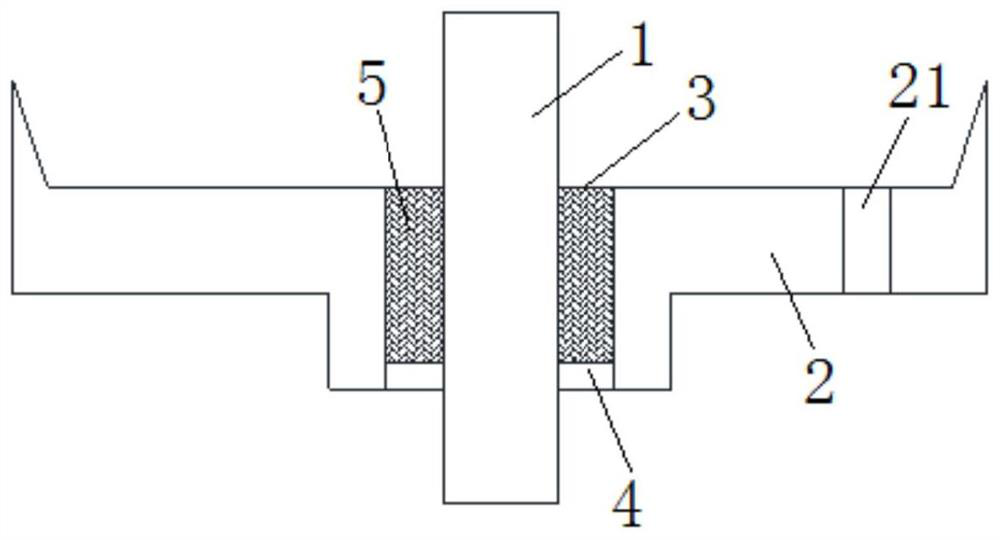

[0053] as attached Figure 6 As shown, a method for manufacturing a battery cover sealing structure is provided in Embodiment 1, comprising the following steps:

[0054] Step 1, cleaning and oxidizing the central pole 1 and the battery cover 2;

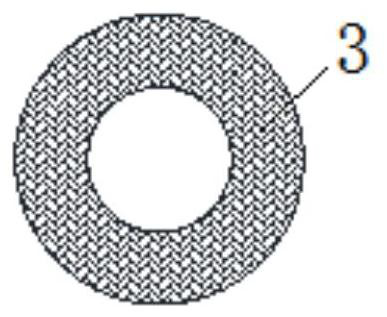

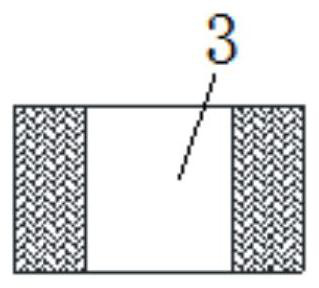

[0055] Step 2. Insert the center pole 1 on the battery cover 2, and reserve an annular gap 5 between the center pole 1 and the battery cover 2; insert the glass fixing body 3 between the center pole 1 and the battery cover 2, and the glass fixed body 3 is sleeved on the central pole 1; under the protection of the atmosphere, after heating and heat preservation treatment, the glass fixed body 3 is respectively connected to the central pole 1 and the battery cover 2 are melted and connected, cooled, and cleaned until the surface of the glass fixed body 3 is bright; wherein, during the heating process, the heating temperature is 920-980°C; the holding time is 10-15min; during the cooling process, the cooling rate is 10-15min;

[0056] ...

Embodiment 2

[0059] as attached Figure 7 As shown, a method for making the sealing structure of the battery is provided in Example 2. The principle of Example 2 is basically the same as that of Example 1, except that in Step 2, the phosphate glass or bismuth glass Prepare a viscous slurry; inject the viscous slurry of phosphate glass or bismuth glass into the annular gap 5, and heat at 100°C for 20 minutes; then raise the temperature to 150°C for 5 minutes, and keep it warm for 20 minutes; Then heat up to 240°C for 5 minutes and keep it warm for 20 minutes; then, under the protection of the atmosphere, heat it to 410-600°C and keep it warm for 10-20 minutes; make the viscous slurry into a glass fixing ring 4, and make the glass fixing ring 4 and The central pole 1, the battery cover 2 and the glass fixed body 3 are closely connected; then cooled to room temperature at a cooling rate of 10-15°C / min to obtain the battery cover sealing structure, and seal the battery cover Cleaning and poli...

Embodiment 3

[0062] as attached Figure 8 As shown, a method for making the battery sealing structure is provided in Example 3. The principle of Example 3 is basically the same as that of Example 1, except that in Step 2, phosphate glass or bismuth glass is used Prepare printing paste; print the printing paste into the annular gap 5 by printing process, heat at 100°C for 20 minutes; then raise the temperature to 150°C for 5 minutes, and keep it warm for 20 minutes; then heat up to 240°C for 5 minutes , and keep it warm for 20 minutes; then, under the protection of the atmosphere, heat it to 410-600°C and keep it warm for 10-20 minutes; make the viscous slurry into a glass fixing ring 4, and make the glass fixing ring 4 respectively connect with the center pole 1, the battery The cover plate 2 and the glass fixed body 3 are closely connected; then cooled to room temperature at a cooling rate of 10-15°C / min to obtain the battery cover sealing structure; and the battery cover sealing structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com