Refining method of rice bran oil retaining oryzanol

A technology for rice bran oil and oryzanol, which is applied in the field of rice bran oil refining with oryzanol retention, can solve the problems of high acidity of rice bran oil, decomposition loss, reduction of nutritional value of rice bran oil, etc., achieve low acid value, reduce the loss of high-temperature decomposition, and improve color and luster. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for refining rice bran oil that retains oryzanol, specifically comprising the following steps:

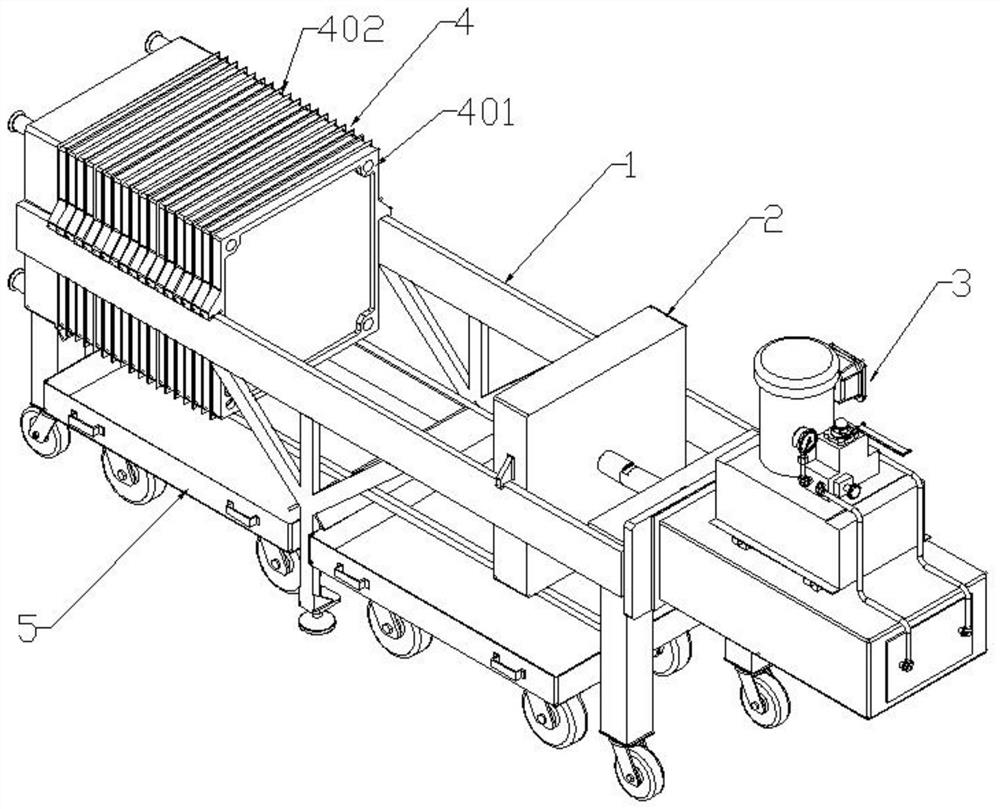

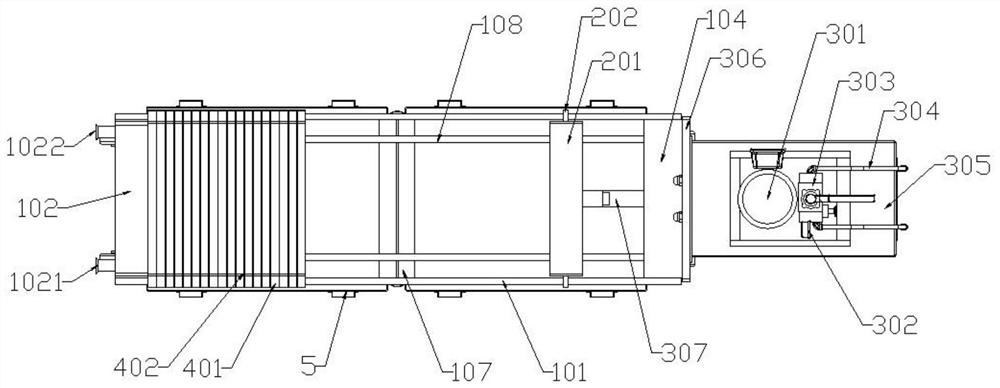

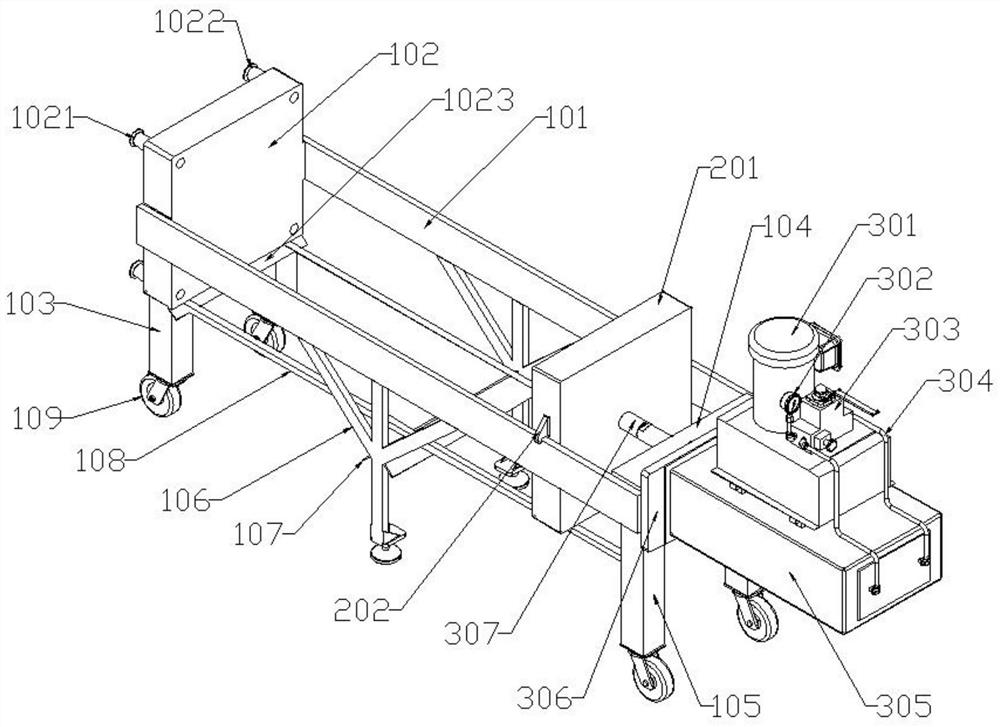

[0037] Step 1, impurity removal: pump crude rice bran oil into the oil inlet pipe 1021 of the filter press and impurity removal equipment, start the air pump 301, and control the reversing switch 303, so that the cylinder rod 307 supports the binder plate assembly 2 to approach the filter frame assembly 4 slide in the direction until the pressure plate assembly 2 compresses the filter frame assembly 4, increasing the pressure of the oil inlet pipe 1021, so that the crude rice bran oil is filled into the filter frame assembly 4, and after filtering and removing impurities, it is obtained at the oil outlet pipe 1022. Trash oil removal;

[0038] Step 2, degumming: Heat the miscellaneous oil to 65°C with a heater, then add food-grade phosphoric acid with a mass fraction of 85%, stir for 15 minutes, cool to 35°C after stirring, add sodium hydroxide with a mass fraction o...

Embodiment 2

[0047] A method for refining rice bran oil that retains oryzanol, specifically comprising the following steps:

[0048] Step 1, impurity removal: pump crude rice bran oil into the oil inlet pipe 1021 of the filter press and impurity removal equipment, start the air pump 301, and control the reversing switch 303, so that the cylinder rod 307 supports the binder plate assembly 2 to approach the filter frame assembly 4 slide in the direction until the pressure plate assembly 2 compresses the filter frame assembly 4, increasing the pressure of the oil inlet pipe 1021, so that the crude rice bran oil is filled into the filter frame assembly 4, and after filtering and removing impurities, it is obtained at the oil outlet pipe 1022. Trash oil removal;

[0049] Step 2, degumming: Heat the miscellaneous oil to 70°C with a heater, then add food-grade phosphoric acid with a mass fraction of 85%, stir for 18 minutes, cool to 37°C after stirring, add sodium hydroxide with a mass fraction o...

Embodiment 3

[0058] A method for refining rice bran oil that retains oryzanol, specifically comprising the following steps:

[0059] Step 1, impurity removal: pump crude rice bran oil into the oil inlet pipe 1021 of the filter press and impurity removal equipment, start the air pump 301, and control the reversing switch 303, so that the cylinder rod 307 supports the binder plate assembly 2 to approach the filter frame assembly 4 slide in the direction until the pressure plate assembly 2 compresses the filter frame assembly 4, increasing the pressure of the oil inlet pipe 1021, so that the crude rice bran oil is filled into the filter frame assembly 4, and after filtering and removing impurities, it is obtained at the oil outlet pipe 1022. Trash oil removal;

[0060] Step 2, degumming: heat the decontamination oil to 75°C with a heater, then add food-grade phosphoric acid with a mass fraction of 85%, stir for 20 minutes, cool to 40°C after the stirring is completed, and add sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com