A processing method for noise-reducing concrete wall panels

A processing method and concrete technology, applied in the manufacture of tools, ceramic products, other household appliances, etc., can solve the problems of affecting the appearance and quality of products, increasing the difficulty of cleaning, restricting production efficiency, etc., and achieving a stable and orderly hardening process of concrete. , The effect of simplifying the production process and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

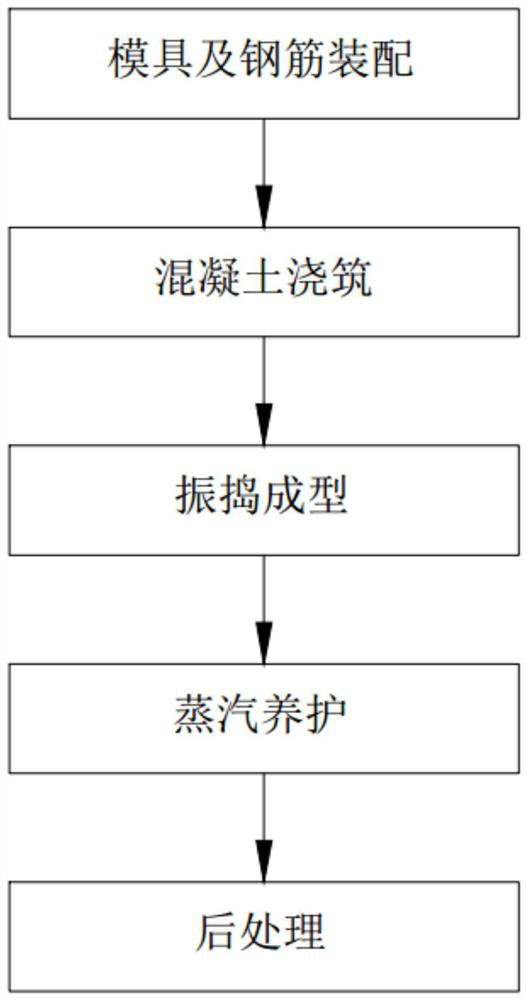

[0039] A method for processing noise-reducing concrete wall panels, comprising the steps of:

[0040] (1) Mold and reinforcement assembly: Assemble the side plate 100 into a rectangle according to the preset shape, and lay it along the track to form a casting mold. The tracks are located on both sides of the casting mold and are used for railcars (not shown in the figure) For walking, a number of equidistant steel wires are fixed on the inner wall of one end of the casting mold, and the other end of the steel wire passes through the other end of the casting mold and is tensioned by traction equipment;

[0041] (2) Concrete pouring: use a crane to hoist the hopper above the pouring mold and at one end of the pouring mold, open the hopper and evenly pour concrete slurry into the pouring mold. The concrete slurry includes the following raw materials in parts by weight: cement 100 150 parts of silica fume, 20 parts of thickener, 50 parts of gravel, 80 parts of foam particles, 50 p...

Embodiment 2

[0051] The rest are the same as in Example 1, except that the concrete slurry comprises the following raw materials in parts by weight: 110 parts of cement, 170 parts of silica fume, 25 parts of thickener, 60 parts of sand and gravel, 90 parts of foam particles, wood 55 parts of fiber, 15 parts of foam stabilizer, 10 parts of water reducing agent;

[0052] The steam curing process is:

[0053] In the stage of heating up and constant temperature, the steam generator will continuously and evenly release steam to the surface of the concrete to raise the temperature to 40°C. The heating time is 3 hours, the heating rate is 8°C / h, and the temperature is kept for 1.2 hours after reaching the preset temperature, and the humidity is 75%. ;

[0054] In the cooling stage, the release of steam is stopped and the temperature is lowered to normal temperature, wherein the cooling rate is 7°C / h.

Embodiment 3

[0056] The rest are the same as in Example 1, except that the concrete slurry comprises the following raw materials in parts by weight: 120 parts of cement, 200 parts of silica fume, 30 parts of thickener, 70 parts of sand and gravel, 100 parts of foam particles, wood 60 parts of fiber, 20 parts of foam stabilizer, 20 parts of water reducing agent;

[0057] The steam curing process is:

[0058] In the stage of heating up and constant temperature, the steam generator will release steam continuously and uniformly to the surface of the concrete to raise the temperature to 50°C. The heating time is 2 hours, and the heating rate is lower than 11°C / h. After rising to the preset temperature, keep warm for 1.8 hours, and the humidity is 85%;

[0059] In the cooling stage, the release of steam is stopped and the temperature is lowered to normal temperature, wherein the cooling rate is 9°C / h.

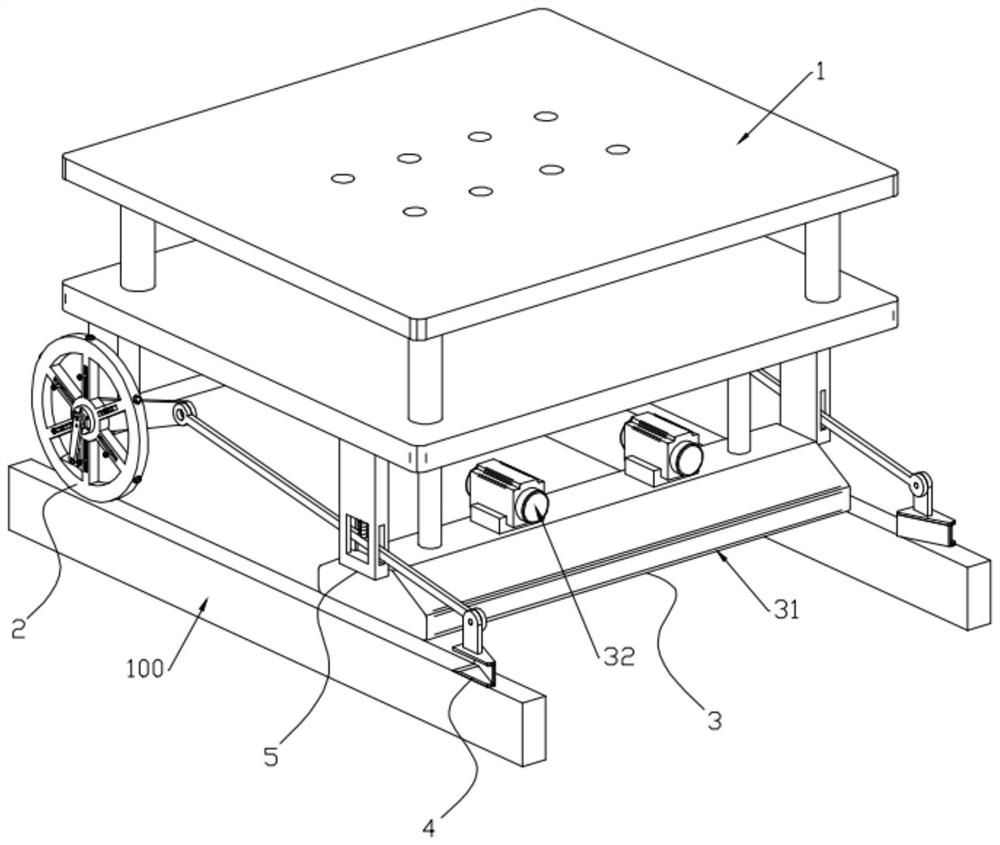

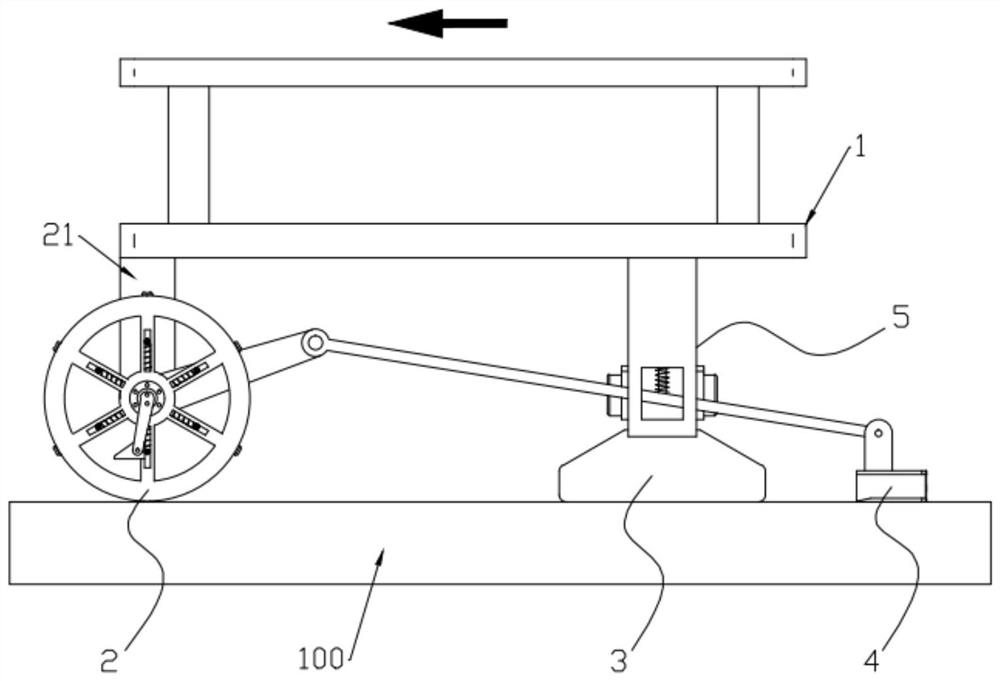

[0060] In the present invention, the forming mechanism includes a machine base 1, a vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com