Efficient energy-saving biodiesel catalyst and preparation method thereof

A biodiesel, high-efficiency and energy-saving technology, used in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc. Green chemistry, easy to produce saponification and other problems, to achieve the effect of low production cost, easy separation and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

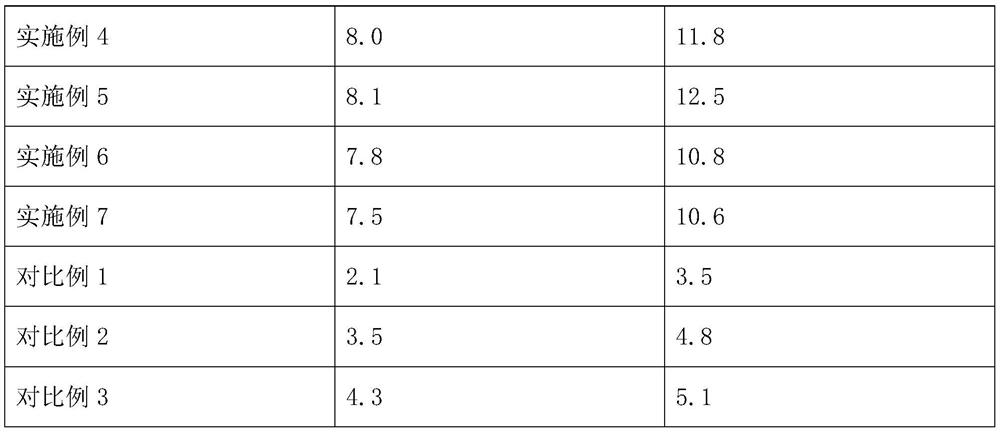

Examples

Embodiment 1

[0024] Weigh 40 parts of methanesulfonic acid, 10 parts of chlorosulfonic acid, 4 parts of modified alumina, 5 parts of glycerol, 15 parts of fatty sulfonic acid, 12 parts of phosphoric acid monoester, 3 parts of tin tetrachloride, 12 parts of polyether acid phosphate, 4 parts of propargyl alcohol, the preparation method of the modified alumina is as follows: the alumina and deionized water are mixed and stirred evenly, and then dried at 120 ° C for 12 hours; Mix the aluminum oxide with ethanol and stir evenly, dry at 120°C for 12 hours, and then treat it at 250°C for 2 hours, mix the alumina, additives, and deionized water obtained above, stir evenly, and then directly filter, separate and dry ; The above-mentioned obtained material was roasted at 450° C. for 3 hours under an argon atmosphere, and then modified alumina was obtained, and the mass ratio of the alumina to deionized water was 1:6. The preparation of the modified alumina In the method, ethanol is absolute ethanol,...

Embodiment 2

[0026] Weigh in turn 42 parts of methanesulfonic acid, 12 parts of chlorosulfonic acid, 5 parts of modified alumina, 6 parts of glycerol, 17 parts of fat sulfonic acid, 13 parts of phosphoric acid monoester, 4 parts of tin tetrachloride, 13 parts of polyether acid phosphate and 5 parts of propargyl alcohol. The preparation method of the modified alumina is as follows: mix the alumina with deionized water and stir evenly, then dry at 130°C for 13 hours; Mix the aluminum oxide with ethanol and stir evenly, dry at 130°C for 13 hours, then treat at 260°C for 3 hours, mix the alumina, additives, and deionized water obtained above, stir evenly, and then directly filter, separate and dry ; The above-mentioned obtained material was roasted at 460° C. for 4 hours under an argon atmosphere, and then modified alumina was obtained, and the mass ratio of the alumina to deionized water was 2:7. The preparation of the modified alumina In the method, ethanol is absolute ethanol, and the mass ...

Embodiment 5

[0032] Weigh 42 parts of methanesulfonic acid, 12 parts of chlorosulfonic acid, 6 parts of modified alumina, 8 parts of glycerol, 17 parts of fat sulfonic acid, 14 parts of phosphoric acid monoester, 3 parts of tin tetrachloride, 13 parts of polyether acid phosphate and 7 parts of propargyl alcohol. The preparation method of the modified alumina is as follows: mix the alumina with deionized water and stir evenly, then dry at 130°C for 15 hours; Mix the aluminum oxide with ethanol and stir evenly, dry at 130°C for 15 hours, and then treat it at 250°C for 2 hours, mix the alumina, additives, and deionized water obtained above, stir evenly, and then directly filter, separate and dry ; The above-mentioned obtained material was roasted at 490° C. for 3 hours under an argon atmosphere, and then modified alumina was obtained, and the mass ratio of the alumina to deionized water was 2:9. The preparation of the modified alumina In the method, ethanol is absolute ethanol, and the mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com