Porous metamorphic loose metal additive, its preparation method and application

A metal additive, multi-porous technology, applied in the field of aluminum alloy process additives, can solve the problems of affecting aluminum alloy material, high energy consumption, human body pollution, etc., and achieve the effect of less impurities, high purity, and pollution solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

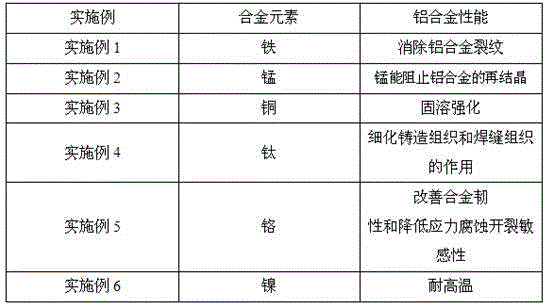

Embodiment 1-6

[0017] Add 99.6% of the alloy powder to the roller or hammer crusher and crush it into a powder with a particle size of 100 microns, add 0.2% of paraffin powder, 0.1% of ammonium bicarbonate, 0.05% of stearic acid and 0.05% of potassium nitrate, and mix The material equipment is mixed and stirred evenly to make a mixture; the mixture is cold-pressed into a round block with a diameter of 30mm~80mm and a height of 2mm to obtain the product.

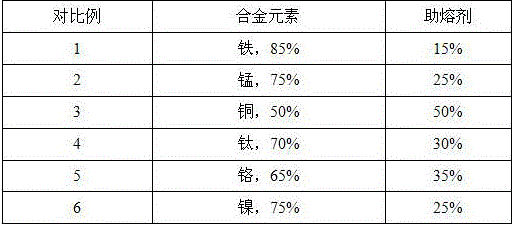

[0018] The alloy powders in Examples 1-6 are shown in Table 1.

[0019] Alloy powders in Table 1 Examples 1-6

[0020]

[0021] The principle of the present invention is: 99.6% of the alloy metal powder is the matrix, that is, the metal of the additive required for the aluminum alloy, such as iron, manganese, copper, titanium, nickel or chromium, which is used to adjust the metal composition in the aluminum alloy to achieve the Different performance requirements of the alloy; 0.2% paraffin powder and 0.1% ammonium bicarbonate are used a...

experiment example

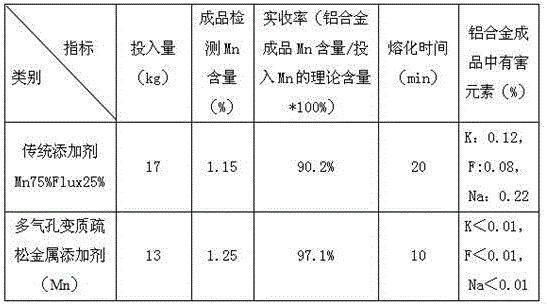

[0029] The products obtained in Example 2 and Comparative Example 2 were respectively added into molten aluminum at 730°C during the preparation of the aluminum alloy, and the quality of the obtained aluminum alloy was tested as shown in Table 3. The table is the comparative test results of using the traditional additive Mn75%Flux25% of Comparative Example 2 and the porous metamorphic loose metal additive (Mn) of Example 2 to make 3A21 aluminum alloy respectively:

[0030] Table 3 The detection results of embodiment 2 and comparative example 2

[0031]

[0032] Note: 1. 3A21 grade aluminum alloy requires the target value of Mn to be 1.25%;

[0033] 2. The total weight of molten aluminum is 1 ton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com