A method for preparing silver oxide-doped manganese oxide nanowire network based on electrospinning and its application in catalytic decomposition of formaldehyde

A manganese oxide nanometer and electrospinning technology, which is applied in the field of nanomaterial manufacturing, can solve the problems of inconspicuous catalytic effect and low long diameter of formaldehyde, and achieve the effects of improved catalytic effect, simple equipment, and safe and convenient connection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

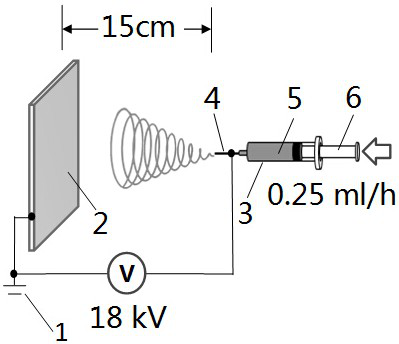

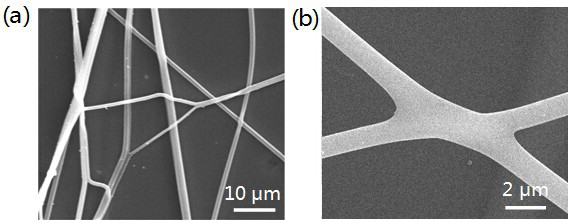

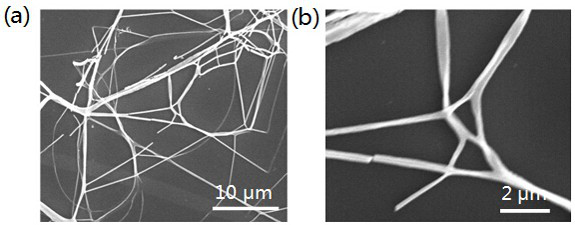

[0026] The present invention provides a method for preparing silver oxide-doped manganese oxide nanowire network based on electrospinning. The method uses polyvinyl alcohol (Polyvinyl Alcohol, PVA) solution and Mn(CH 3 COO) 2 Solution configuration electrospinning precursor solution, and then after high temperature calcination and KMnO 4 solution soaking, and finally silver nanowires are dispersed in manganese oxide nanowires, and doping is achieved by oxygen plasma treatment. The specific implementation steps are as follows:

[0027] (1) Spinning so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com