Shale reservoir methane in-situ multi-stage pulse energy-gathering blasting fracturing method

A technology for shale reservoirs and explosion fracturing, which is applied in drilling equipment and methods, earthwork drilling, and fluid production, etc., can solve problems such as high development costs and environmental pollution, and achieve wide practicability, economy and environmental protection. Obvious advantages and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is further described below in conjunction with the embodiment in the accompanying drawings:

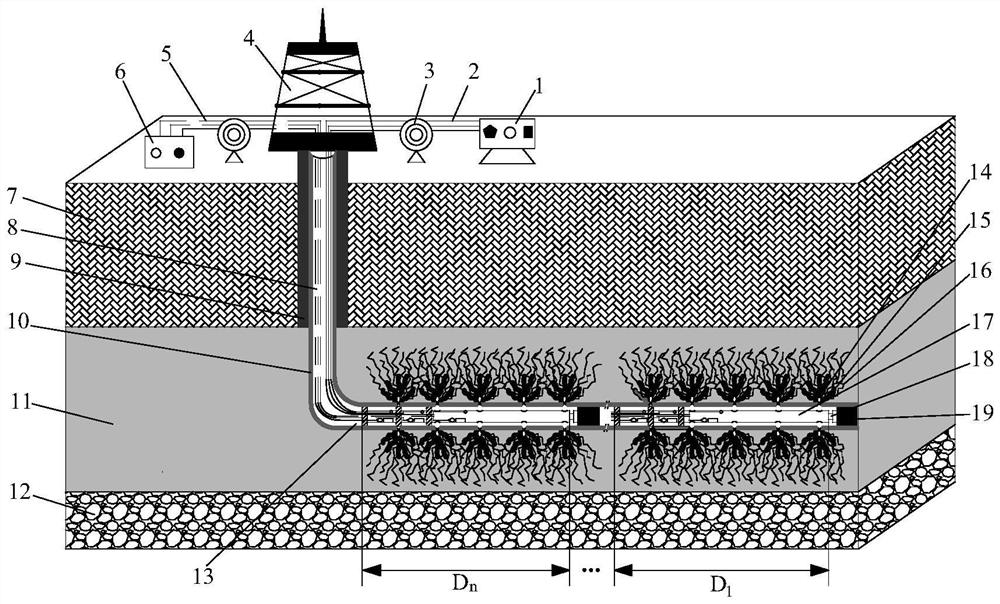

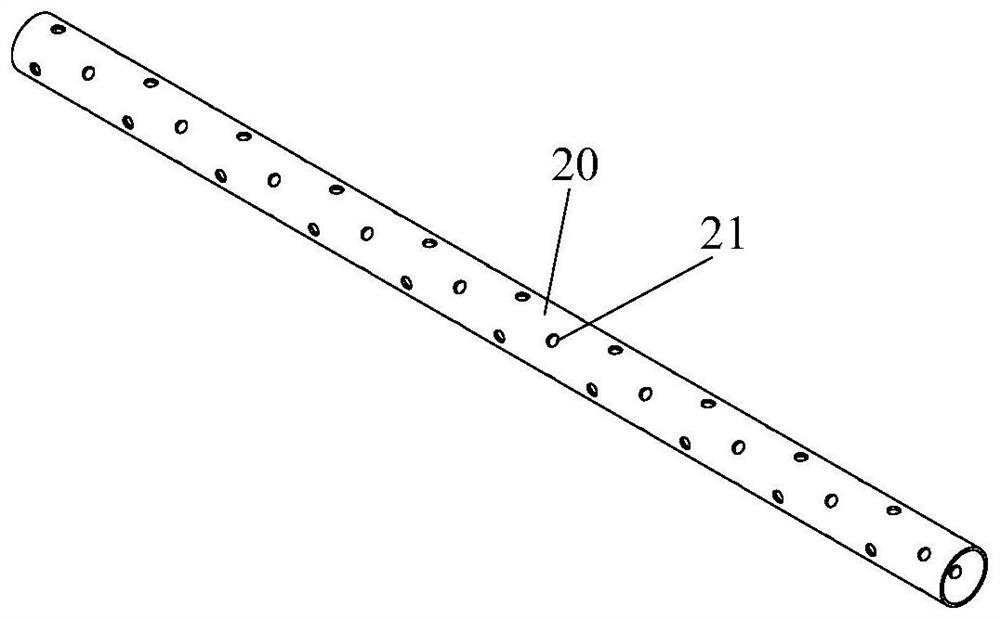

[0022] Such as Figure 1-Figure 3 As shown, the present invention is an in-situ multi-stage pulse energy-concentrated explosion fracturing method for methane in shale reservoirs, using a methane concentration monitor 1, a drilling fracturing platform 4, an electric ignition device 6, and a pulse energy-concentrated explosion tube The steps for implementing the methane in-situ multi-stage pulse shaped energy detonation fracturing method are as follows:

[0023] a. Construction of horizontal wells: the drilling and fracturing platform 4 controls the directional drilling rig to construct in the selected area, penetrates the ground rock layer 7 and enters the deep shale reservoir 11, first completes the construction of the vertical well 8, and then adjusts the direction of the directional drilling rig bit on the page The rock reservoir 11 needs to be fracture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com