A method for preparing macro-sized porous ZNO by electrochemical corrosion

An electrochemical and dimensional technology, used in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of high sintering temperature and high cost, and achieve the effect of uniform distribution, overall integrity and great application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

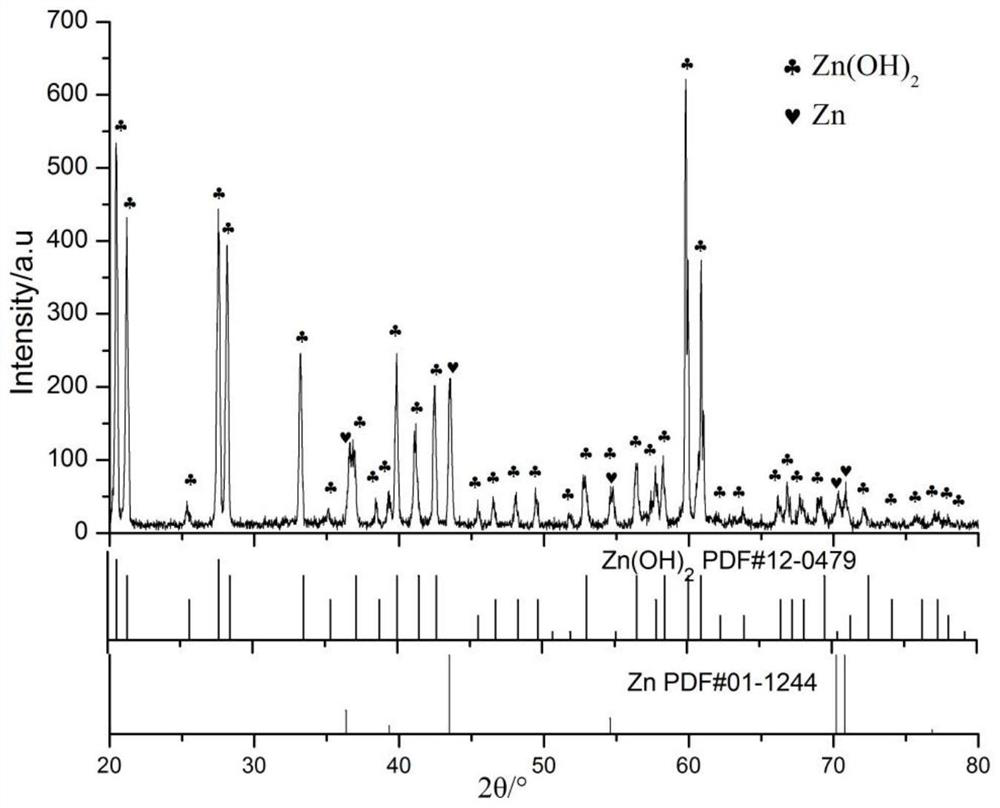

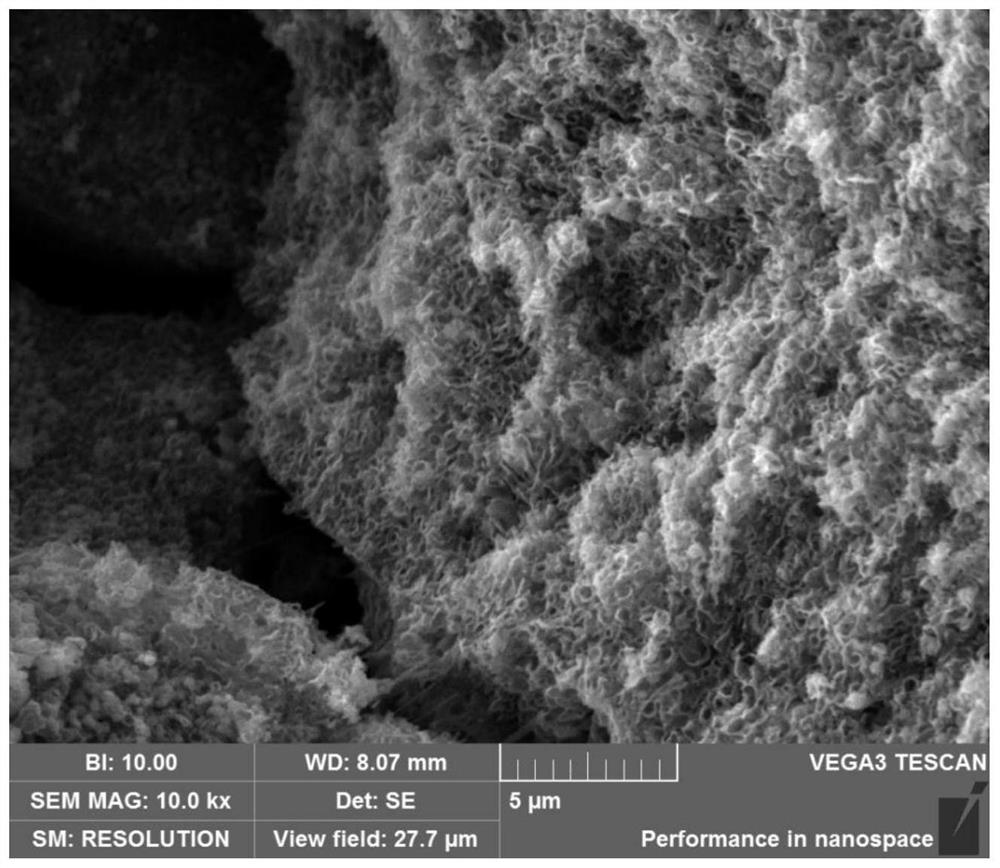

Image

Examples

Embodiment 1

[0035] The present invention prepares a method for macroscopic porous ZnO by electrochemical corrosion, and the specific operation steps are as follows:

[0036] Step 1, raw material preparation:

[0037] According to Zn mass fraction 20%, weigh 20g industrial pure Zn and 80g industrial pure Al;

[0038] Step 2, alloy profile preparation:

[0039] First heat the resistance furnace to 200°C, put Al in the crucible when melting, and add Zn to the melt after part of the charge is melted. The melting temperature is 700°C, after Zn and Al are uniformly mixed, the alloy liquid is rolled and pressed into sheets, and the thickness of the alloy sheet is 1mm;

[0040] Step 3, alloy solution treatment:

[0041] Heating the alloy sheet in step 2 for solution treatment, then subjecting the alloy sheet after solution treatment at 380°C for 4 hours to water quenching to obtain a profile;

[0042] Step 4, electrochemical corrosion dealloying treatment:

[0043] The alloy profiles obtaine...

Embodiment 2

[0047] The present invention prepares a method for macroscopic porous ZnO by electrochemical corrosion, and the specific operation steps are as follows:

[0048] Step 1, raw material ratio:

[0049] According to Zn content 20%, weigh 20g industrial pure Zn and 80g industrial pure Al;

[0050] Step 2, alloy profile preparation:

[0051] First heat the resistance furnace to 200°C, put Al in the crucible when melting, and add Zn to the melt after part of the charge is melted. The melting temperature is 700°C, after Zn and Al are uniformly mixed, the alloy liquid is rolled and pressed into sheets, and the thickness of the alloy sheet is 1mm;

[0052] Step 3, alloy solution treatment:

[0053] Heating the alloy sheet in step 2 for solution treatment, then subjecting the alloy sheet after solution treatment at 380°C for 4 hours to water quenching to obtain a profile;

[0054] Step 4, electrochemical corrosion dealloying treatment:

[0055] The alloy profiles obtained in step 3 ...

Embodiment 3

[0059]The present invention prepares a method for macroscopic porous ZnO by electrochemical corrosion, and the specific operation steps are as follows:

[0060] Step 1, raw material preparation:

[0061] According to the Zn content of 30%, weigh 30g industrial pure Zn and 70g industrial pure Al;

[0062] Step 2, alloy profile preparation:

[0063] First heat the resistance furnace to about 200°C, put Al in the crucible when melting, and add Zn to the melt when part of the charge is melted. The melting temperature is 700°C, after Zn and Al are uniformly mixed, the alloy liquid is rolled and pressed into sheets, and the thickness of the alloy sheet is 0.8mm;

[0064] Step 3, alloy solution treatment:

[0065] Heating the alloy sheet in step 2 for solution treatment, then subjecting the alloy sheet after solution treatment at 380°C for 4 hours to water quenching to obtain a profile;

[0066] Step 4, electrochemical corrosion dealloying treatment:

[0067] The alloy sheet obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com