Gamma-aminobutyric acid lactobacillus plantarum leavening agent and application thereof in fermentation of pickled vegetables

A technology of Lactobacillus plantarum and aminobutyric acid, applied in the field of starter, can solve the problems of single variety of kimchi, no health care effect, low nutritional content, etc., achieve food safety, promote liver function and kidney function, and improve mental depression. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

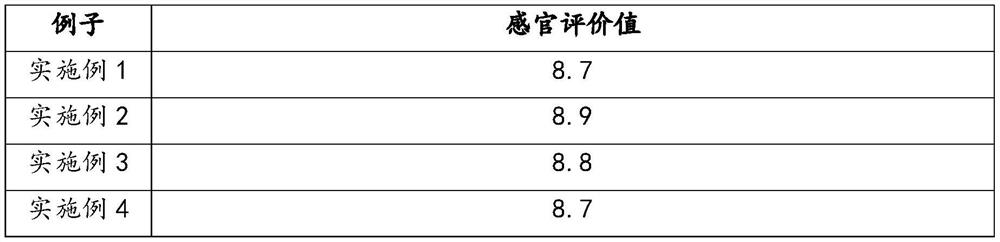

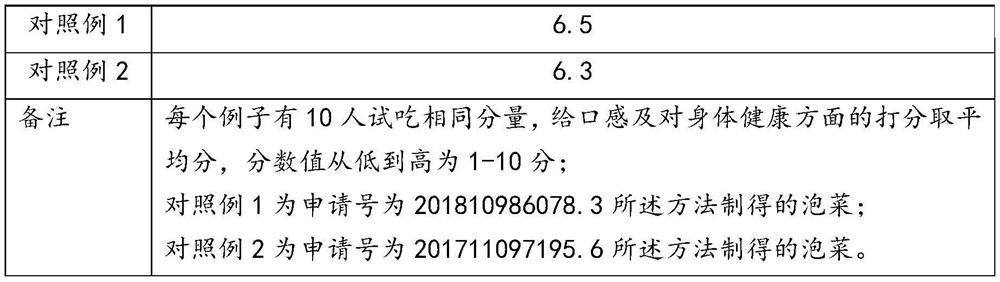

Examples

Embodiment 1

[0034] Preparation of Lactobacillus plantarum 29MJ-2 direct-throwing starter:

[0035] A. Lactobacillus plantarum 29MJ-2 preserved in glycerol tubes was inoculated into MRS liquid medium at a ratio of 2%, cultured statically at 37° C. for 16 hours, and activated for 3 generations.

[0036] B. Inoculate the activated seeds into the fermenter at 2%, culture at 37°C for 12 hours, control the pH to 5.8, centrifuge the bacterial solution at 10,000r / min for 15 minutes, discard the supernatant, collect the bacterial sludge, add trehalose and malt paste Essence, sucrose, mannitol, and Tween-80 are used as a mixed protective agent, and then vacuum freeze-dried to prepare a direct-throwing starter.

[0037] Among them, the components in the Lactobacillus plantarum 29MJ-2 direct-injection starter are, by mass percentage: 65% of Lactobacillus plantarum, 20% of trehalose, 10% of maltodextrin, 3% of sucrose, 0.2% of mannitol, and Temperature-80 0.2%, the number of viable Lactobacillus plan...

Embodiment 2

[0045] Preparation of Lactobacillus plantarum 29MJ-2 direct-throwing starter:

[0046]A. Lactobacillus plantarum 29MJ-2 preserved in glycerol tubes was inoculated into MRS liquid medium at a ratio of 2%, cultured statically at 37° C. for 16 hours, and activated for 3 generations.

[0047] B. Inoculate the activated seeds into the fermenter at 2%, culture at 37°C for 12 hours, control the pH to 5.8, centrifuge the bacterial solution at 6000r / min for 15 minutes, discard the supernatant, collect the bacterial sludge, add trehalose and malt paste Essence, sucrose, mannitol, and Tween-80 are used as a mixed protective agent, and then vacuum freeze-dried to prepare a direct-throwing starter.

[0048] Among them, the components in the Lactobacillus plantarum 29MJ-2 direct-injection starter are, by mass percentage: 65% of Lactobacillus plantarum, 20% of trehalose, 10% of maltodextrin, 3% of sucrose, 0.2% of mannitol, and Temperature-80 0.2%, the number of viable Lactobacillus plantar...

Embodiment 3

[0056] Preparation of Lactobacillus plantarum 29MJ-2 direct-throwing starter:

[0057] A. Lactobacillus plantarum 29MJ-2 preserved in glycerol tubes was inoculated into MRS liquid medium at a ratio of 2%, cultured statically at 37° C. for 16 hours, and activated for 3 generations.

[0058] B. Inoculate the activated seeds into the fermenter at 2%, culture at 37°C for 12 hours, control the pH to 5.8, centrifuge the bacterial solution at 10,000r / min for 15 minutes, discard the supernatant, collect the bacterial sludge, add trehalose and malt paste Essence, sucrose, mannitol, and Tween-80 are used as a mixed protective agent, and then vacuum freeze-dried to prepare a direct-throwing starter.

[0059] Among them, the components in the Lactobacillus plantarum 29MJ-2 direct-injection starter are, by mass percentage: 65% of Lactobacillus plantarum, 20% of trehalose, 10% of maltodextrin, 3% of sucrose, 0.2% of mannitol, and Temperature-80 0.2%, the number of viable Lactobacillus plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com