Temperature-resistant and salt-tolerant high-efficiency filtrate reducer for drilling fluid and preparation method thereof

A technology of temperature and salt resistance, fluid loss control agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the failure, thermal decomposition of polymer fluid loss control agent, temperature resistance, temperature resistance performance To achieve the effect of improving temperature and salt resistance, excellent filtration performance, and excellent temperature and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

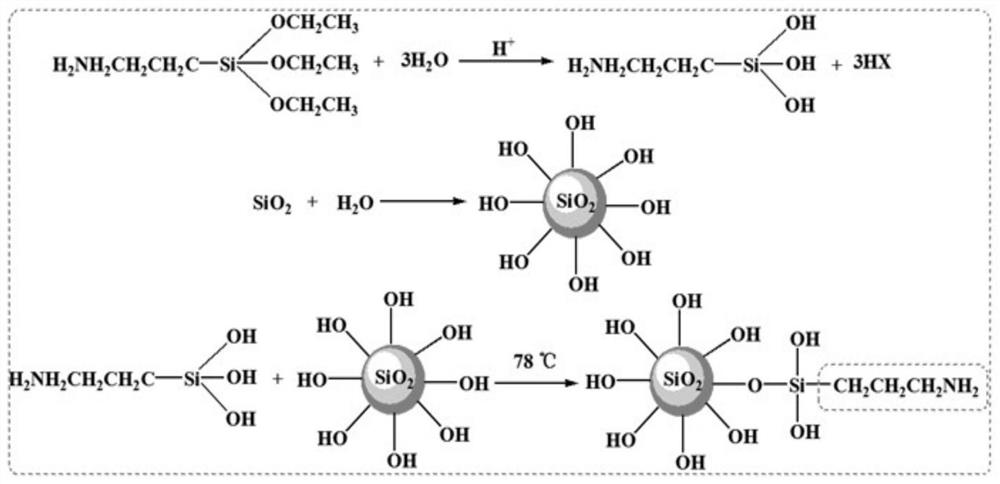

Method used

Image

Examples

Embodiment 1

[0059] The invention relates to a method for preparing a temperature-resistant and salt-resistant high-efficiency fluid loss reducer for drilling fluid, which is specifically implemented according to the following steps:

[0060] Step 1, preparing zwitterionic polymers by free radical polymerization in aqueous solution, specifically:

[0061] Step 1.1, weigh the following components according to mass percentage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS) 10%, maleic anhydride (MA) 5%, methacryloyloxyethyltrimethyl Ammonium chloride (DMC) 7.5%, sodium styrene sulfonate (SSS) 2.5%, calcium sulfate whisker (CSW) 1.5%, ammonium persulfate (APS) 2.5%, the balance is deionized water, the mass of the above components The sum of the percentages is 100%;

[0062] Step 1.2, pretreatment stage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), maleic anhydride (MA) are dissolved in 33wt% deionized water, and placed in a device with cooling reflux and electric stirring In a four-n...

Embodiment 2

[0074] The invention relates to a method for preparing a temperature-resistant and salt-resistant high-efficiency fluid loss reducer for drilling fluid, which is specifically implemented according to the following steps:

[0075] Step 1, preparing zwitterionic polymers by free radical polymerization in aqueous solution, specifically:

[0076] Step 1.1, weigh the following components according to mass percentage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS) 10%, maleic anhydride (MA) 5%, methacryloyloxyethyltrimethyl Ammonium chloride (DMC) 5%, sodium styrene sulfonate (SSS) 5%, calcium sulfate whisker (CSW) 1.5%, ammonium persulfate (APS) 2.5%, and the balance is deionized water. The sum of the percentages is 100%;

[0077] Step 1.2, pretreatment stage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), maleic anhydride (MA) are dissolved in 33wt% deionized water, and placed in a device with cooling reflux and electric stirring In a four-necked flask; methacryloxyethyltri...

Embodiment 3

[0088] The invention relates to a method for preparing a temperature-resistant and salt-resistant high-efficiency fluid loss reducer for drilling fluid, which is specifically implemented according to the following steps:

[0089] Step 1, preparing zwitterionic polymers by free radical polymerization in aqueous solution, specifically:

[0090] Step 1.1, weigh the following components according to mass percentage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS) 12.5%, maleic anhydride (MA) 2.5%, methacryloyloxyethyltrimethyl Ammonium chloride (DMC) 5%, sodium styrene sulfonate (SSS) 5%, calcium sulfate whisker (CSW) 1.5%, ammonium persulfate (APS) 2.5%, and the balance is deionized water. The sum of the percentages is 100%;

[0091] Step 1.2, pretreatment stage: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), maleic anhydride (MA) are dissolved in 33wt% deionized water, and placed in a device with cooling reflux and electric stirring In a four-necked flask; methacryloxyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com