Composition, temperature-resistant salt-resistant fracturing fluid thickening agent prepared from composition, and preparation method thereof

A fracturing fluid thickener, temperature-resistant and salt-resistant technology, applied in the field of temperature-resistant and salt-resistant fracturing fluid thickener and its preparation, and preparation of temperature-resistant and salt-resistant fracturing fluid thickener composition field, can solve Few studies have been done to achieve the effects of complete gel breaking, improved salt resistance, and slow viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of a temperature-resistant and salt-resistant fracturing fluid thickener, the preparation method comprising the following steps:

[0040] (1) Mix the composition provided by the present invention and 507 to 700 parts by weight of the second solvent (for example, it can be 507, 600 or 700 parts by weight), and adjust the pH of the mixing system to 6.5 to 6.8 (for example, it can be 6.5, 6.6, 6.7 or 6.8), then add 0.01 to 0.025 parts by weight of a molecular weight regulator (for example, 0.01, 0.02 or 0.025 parts by weight) to the mixed system, pass nitrogen to remove oxygen, and then add the initiator system to the mixed system 0.001~0.5 parts by weight (for example, it can be 0.001, 0.01, 0.1, 0.2, 0.4 or 0.5 parts by weight) at 10~12°C (for example, it can be 10°C, 11°C or 12°C) to initiate the polymerization reaction, and the reaction ends Finally, the temperature-resistant and salt-resistant fracturing fluid t...

Embodiment 1

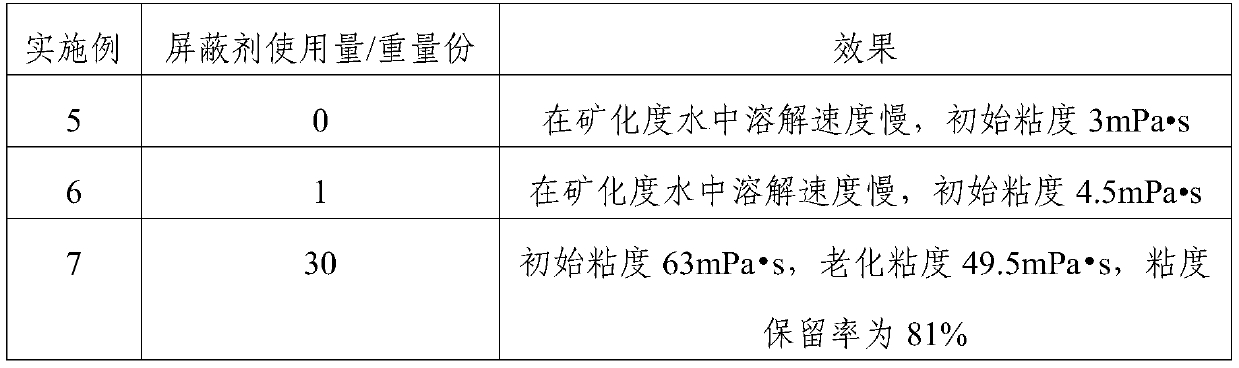

[0046] Prepare shielding agent

[0047] The preparation raw materials include: 130 parts by weight of acrylic acid, 13 parts by weight of maleic anhydride, 13 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, 8 parts by weight of sodium methacrylate, 85 parts by weight of sodium hydroxide, and 751 parts by weight of ionized water, 0.5 parts by weight of sodium formate, 0.08 parts by weight of ammonium persulfate, and 0.04 parts by weight of sodium bisulfite.

[0048] The preparation method comprises the following steps:

[0049] Add acrylic acid, maleic anhydride, 2-acrylamide-2-methylpropanesulfonic acid, sodium methacrylsulfonate and deionized water into the reactor, after fully dissolving, adjust the pH value of the solution with sodium hydroxide, and adjust the pH The value is adjusted between 7.0-7.2, and sodium formate is added at the same time;

[0050] Deoxygenate with nitrogen for 60 minutes, add ammonium persulfate and sodium bisulfite in turn, and poly...

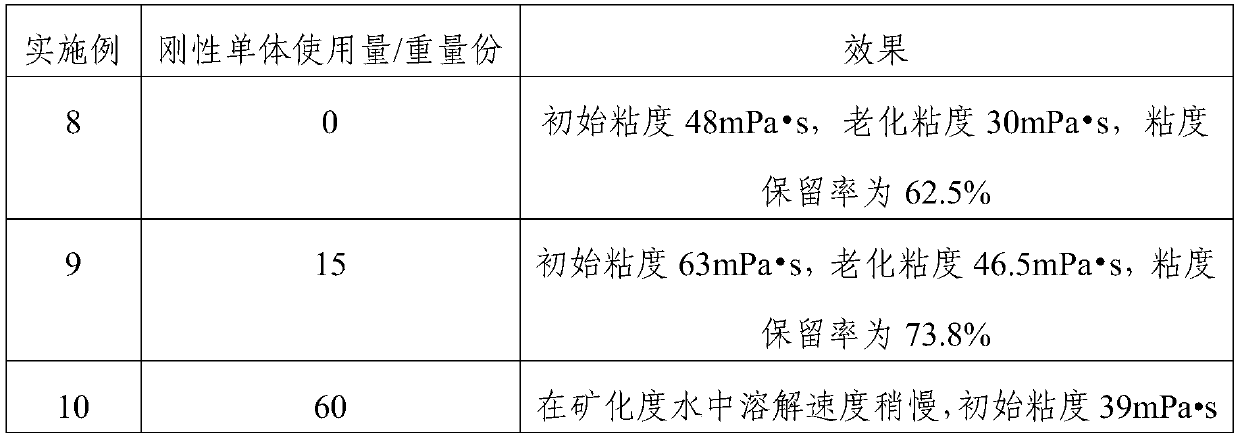

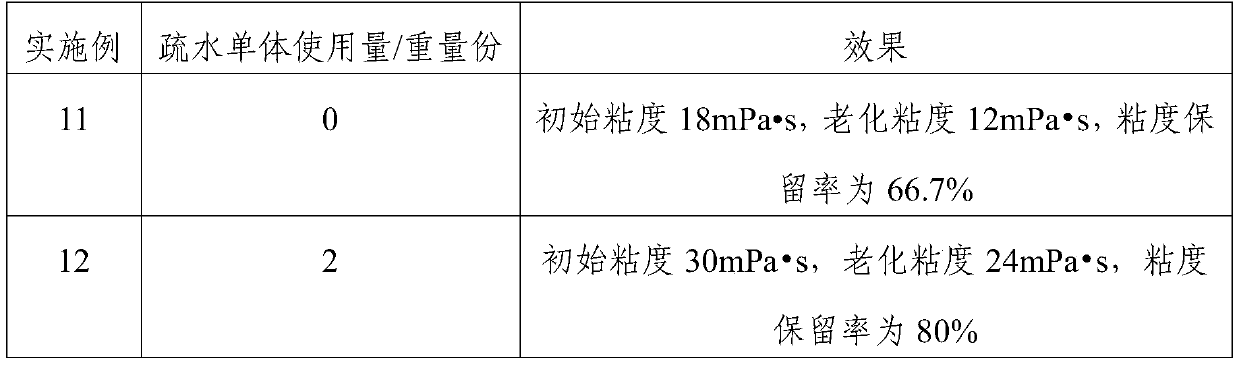

Embodiment 2

[0054] The preparation raw materials include: 215 parts by weight of acrylamide, 45 parts by weight of acrylic acid, 8 parts by weight of N,N-di-n-octyl acrylamide, 20 parts by weight of 2-acrylamide-2-methylpropanesulfonic acid, p-styrenesulfonic acid 40 parts by weight of sodium, 1.5 parts by weight of sodium lauryl sulfate, 15 parts by weight of shielding agent, 29 parts by weight of sodium hydroxide, 626.5 parts by weight of deionized water, 0.12 parts by weight of sodium formate, azobisisobutylamidine dihydrochloride 0.15 parts by weight, 0.02 parts by weight of potassium persulfate and 0.015 parts by weight of sodium bisulfite.

[0055] The preparation method comprises the following steps:

[0056] Add acrylamide, acrylic acid, N,N-di-n-octyl acrylamide, 2-acrylamide-2-methylpropanesulfonic acid, sodium p-styrenesulfonate, sodium lauryl sulfate, After the shielding agent and deionized water are fully dissolved, adjust the pH value of the solution with sodium hydroxide t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com