Temperature-resistant salt-resistant profile control plugging agent and preparation method thereof

The technology of profile control and water shutoff agent and regulator is applied in the directions of chemical instruments and methods, drilling compositions, etc., and can solve the problems of general temperature resistance and salt resistance, high formation water salinity, and high formation temperature of oil wells. Achieve the effect of improving thermal stability and salt resistance, high viscosity and high gel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

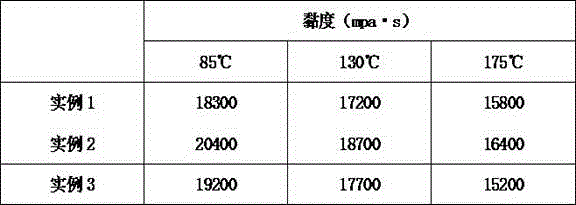

Examples

example 1

[0026] Preparation of temperature and salt resistance polyacrylamide:

[0027] The raw materials in parts by weight are: acrylamide 200, acrylic acid 50, 2-acrylamide-2-methylpropanesulfonic acid 15, styrene sodium sulfonate 4, sodium hydroxide 30.6, deionized water 700, sodium formate 0.002, azobisiso Butyronitrile 0.3, potassium persulfate 0.012, sodium bisulfite 0.008. The temperature and salt resistance polyacrylamide has a molecular weight of 18.9 million and a degree of hydrolysis of 20%.

[0028] Preparation of temperature and salt resistance profile control and water shutoff agent:

[0029] The weight parts of raw materials are: temperature and salt resistance polyacrylamide 1.5, hexamethylol melamine 0.4, aluminum citrate 0.06, ethylenediamine tetramethylene phosphate sodium 0.07, ammonium acetate 3, water 995.

[0030] Add ammonium acetate to the water, after fully dissolving, add temperature and salt-resistant polyacrylamide, stir at room temperature for 3 hours, then add ...

example 2

[0032] Preparation of temperature and salt resistance polyacrylamide:

[0033] The weight parts of raw materials are: acrylamide 170, acrylic acid 30, 2-acrylamide-2-methylpropanesulfonic acid 10, styrene sodium sulfonate 3, sodium hydroxide 18.6, deionized water 768, sodium formate 0.0012, azobisiso Butyronitrile 0.3, potassium persulfate 0.012, sodium bisulfite 0.008. The temperature and salt-resistant polyacrylamide has a molecular weight of 20.2 million and a degree of hydrolysis of 15%.

[0034] Preparation of temperature and salt resistance profile control and water shutoff agent:

[0035] The parts by weight of the raw materials are: temperature-resistant and salt-resistant polyacrylamide 2, hexamethylolmelamine 0.6, aluminum citrate 0.05, sodium ethylenediamine tetramethylene phosphate 0.04, ammonium acetate 5, and water 992.

[0036] Add ammonium acetate to the water, after fully dissolving, add temperature and salt-resistant polyacrylamide, stir at room temperature for 3 ho...

example 3

[0038] Preparation of temperature and salt resistance polyacrylamide:

[0039] The parts by weight of raw materials are: acrylamide 150, acrylic acid 45, 2-acrylamide-2-methylpropanesulfonic acid 20, styrene sodium sulfonate 5, sodium hydroxide 28.8, deionized water 751, sodium formate 0.0008, azobisiso Butyronitrile 0.3, potassium persulfate 0.012, sodium bisulfite 0.008. The temperature and salt resistance polyacrylamide has a molecular weight of 22.6 million and a degree of hydrolysis of 23%.

[0040] Preparation of temperature and salt resistance profile control and water shutoff agent:

[0041] The weight parts of the raw materials are: temperature-resistant and salt-resistant polyacrylamide 2.5, hexamethylolmelamine 0.8, aluminum citrate 0.03, ethylenediamine tetramethylene phosphate sodium 0.05, ammonium acetate 4, and water 992.6.

[0042] Add ammonium acetate to the water, after fully dissolving, add temperature and salt-resistant polyacrylamide, stir at room temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com