A kind of medium strong base styrene series amphoteric ion exchange resin and preparation method thereof

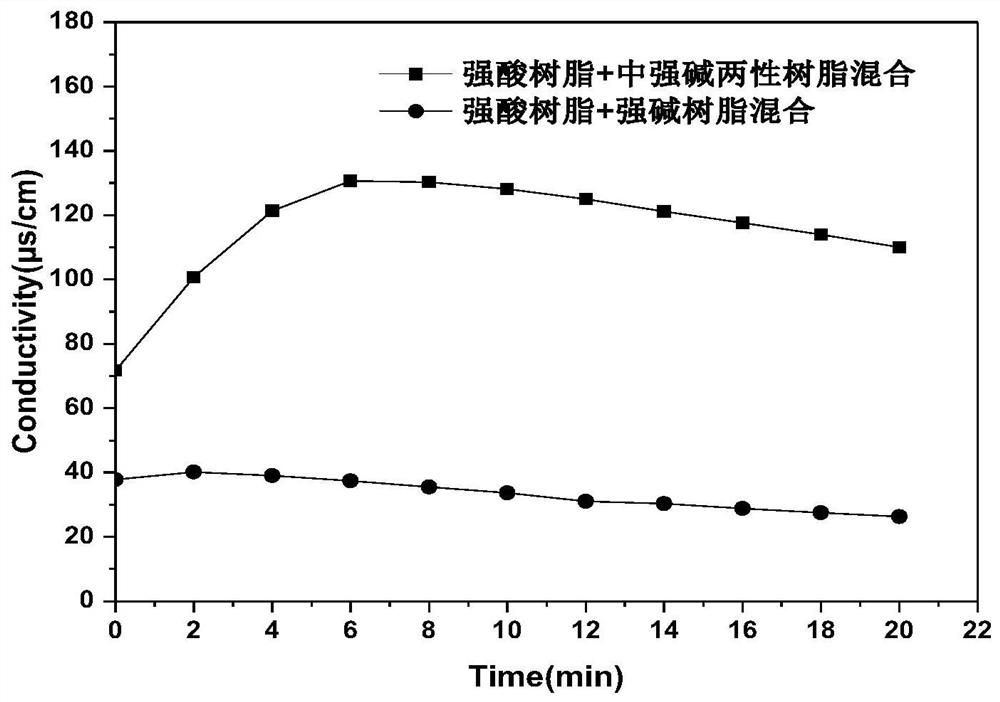

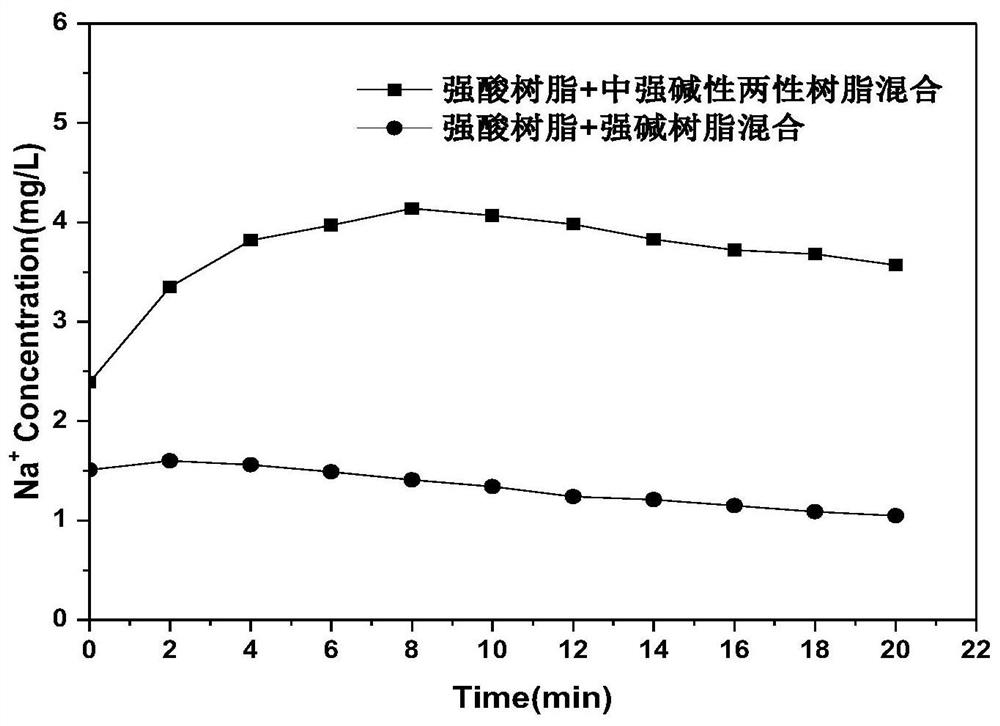

A technology of amphoteric ion and exchange resin, which is applied in the fields of amphoteric ion exchange resin and its preparation, medium and strong base styrene series amphoteric ion exchange resin and its preparation, and can solve the problems of poor electric regeneration effect of strong acid and strong alkali mixed resin, etc. Achieve good adsorption performance, expand the application range, and improve the performance of electric regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

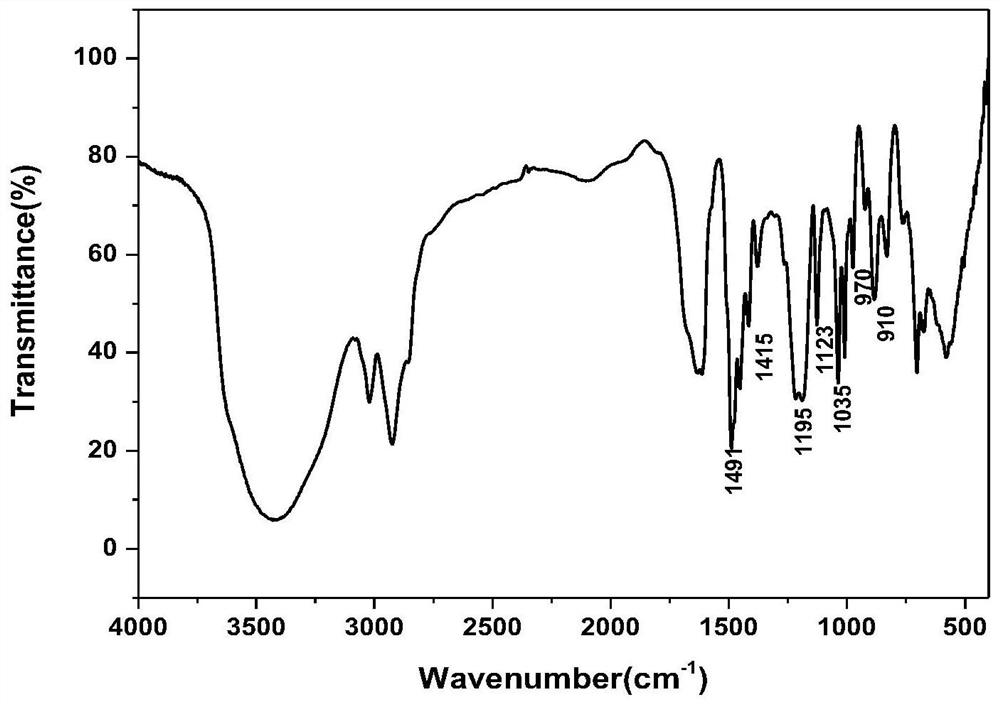

Method used

Image

Examples

Embodiment 1

[0026] A kind of strong base polystyrene series amphoteric ion exchange resin, the raw material composition and content of its weight part are as follows:

[0027]

[0028]

[0029] The preparation method of above-mentioned medium-strongly basic polystyrene series amphoteric ion exchange resin specifically comprises the steps:

[0030] (1) Sulfonation reaction and transformation of cross-linked polystyrene resin

[0031] Add 20 parts of cross-linked polystyrene resin, 20 parts of 1,2-dichloroethane, and 40 parts of concentrated sulfuric acid into the reaction vessel in sequence. The temperature is controlled at 40-60°C, the speed is 900r / min, and the reaction time is 30- After 40min, the reaction solution was filtered after the reaction, and the obtained cross-linked polystyrene resin was washed with 5% aqueous sodium hydroxide solution and 5% aqueous hydrochloric acid solution successively, and then washed with deionized water until the pH of the effluent was 7. Vacuum...

Embodiment 2

[0038] A kind of strong base polystyrene series amphoteric ion exchange resin, the raw material composition and content of its weight part are as follows:

[0039]

[0040]

[0041] The preparation method of above-mentioned medium-strong base series polystyrene series amphoteric ion exchange resin specifically comprises the steps:

[0042] (1) Sulfonation reaction and transformation of cross-linked polystyrene resin

[0043]Add 25 parts of cross-linked polystyrene resin, 50 parts of 1,2-dichloroethane, and 50 parts of concentrated sulfuric acid into the reaction vessel in sequence. The temperature is controlled at 40-60°C, the rotation speed is 900r / min, and the reaction time is 30- After 40min, the reaction solution was filtered after the reaction, and the obtained cross-linked polystyrene resin was washed with 5% aqueous sodium hydroxide solution and 5% aqueous hydrochloric acid solution successively, and then washed with deionized water until the pH of the effluent wa...

Embodiment 3

[0050] A kind of strong base polystyrene series amphoteric ion exchange resin, the raw material composition and content of its weight part are as follows:

[0051]

[0052] The preparation method of above-mentioned medium-strong base series polystyrene series amphoteric ion exchange resin specifically comprises the steps:

[0053] (1) Sulfonation reaction and transformation of cross-linked polystyrene resin

[0054] Add 30 parts of cross-linked polystyrene resin, 60 parts of 1,2-dichloroethane, and 60 parts of concentrated sulfuric acid into the reaction vessel in sequence. The temperature is controlled at 40-60°C, the speed is 900r / min, and the reaction time is 30- After 40min, the reaction solution was filtered after the reaction, and the obtained cross-linked polystyrene resin was washed with 5% aqueous sodium hydroxide solution and 5% aqueous hydrochloric acid solution successively, and then washed with deionized water until the pH of the effluent was 7. Vacuum drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com