Preparation method of high-activity low-byproduct propylene gas-phase epoxidation catalyst

An oxidation system and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of ineffective decomposition of hydrogen peroxide, limit the number of Ti active sites in TS-1 molecular sieve, and avoid multi-step The treatment process, excellent catalytic activity, and the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

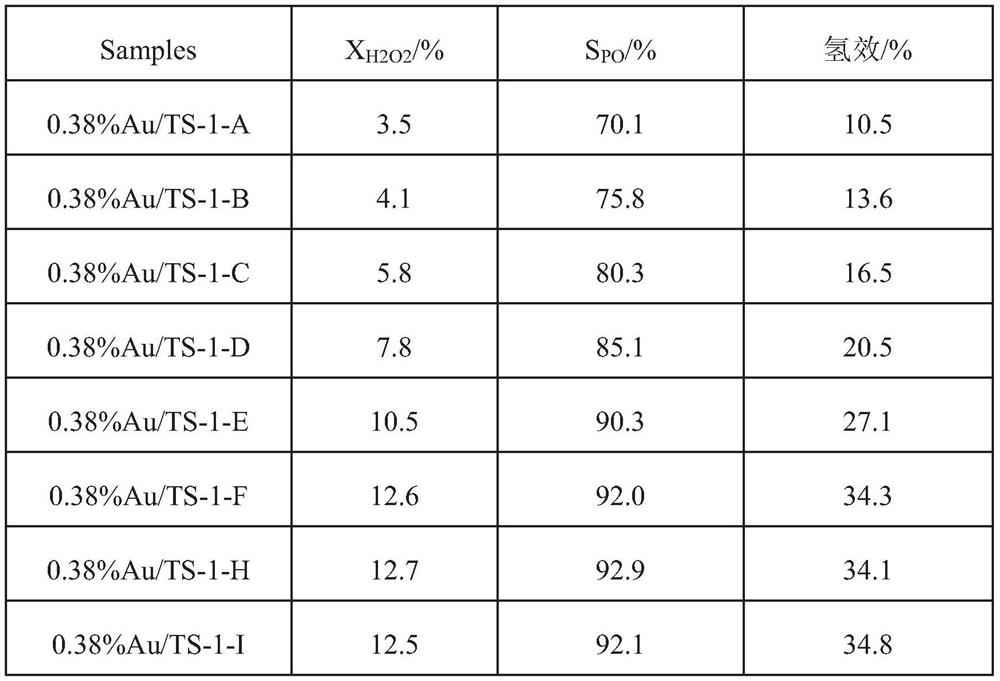

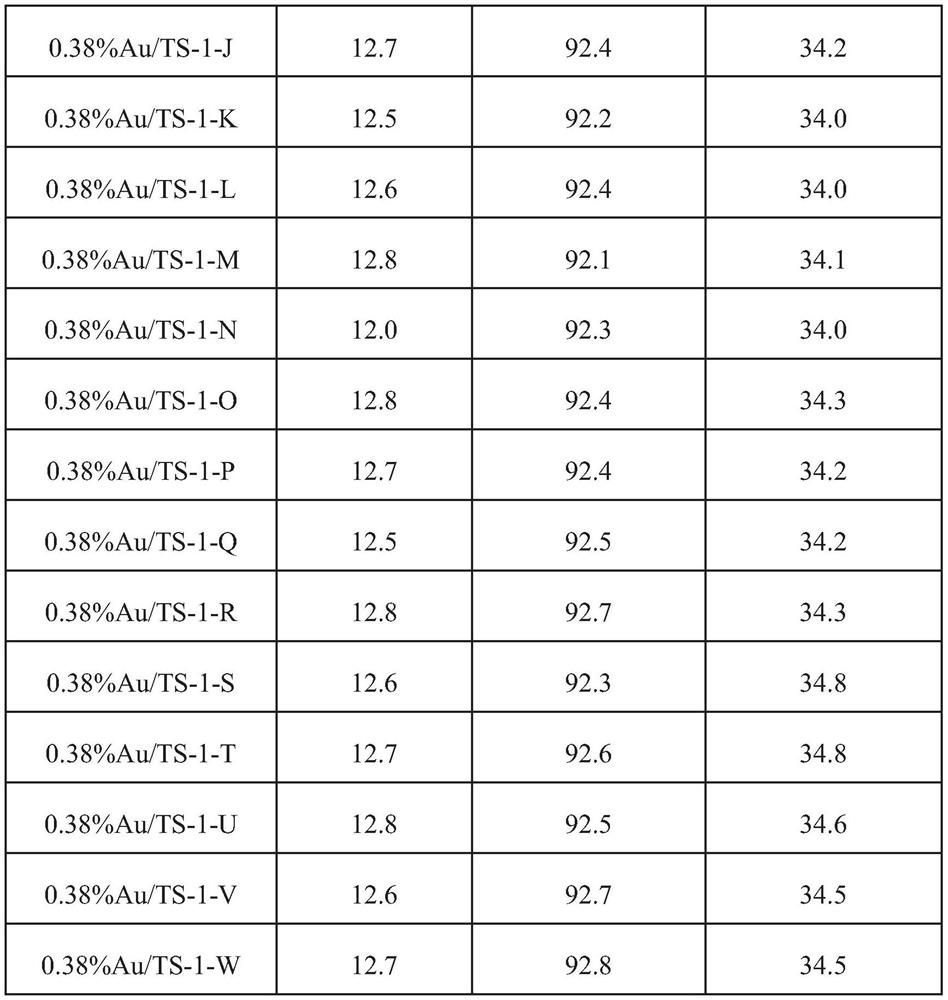

Embodiment 1

[0045] Add 0.2g of soluble starch and 38g of water into the beaker and stir, then add 44g of 25wt% TPAOH aqueous solution and 46.2g of tetraethyl orthosilicate in sequence, and hydrolyze at 30°C for 3h to obtain a silicon source hydrolysis mixture; 3.8g of titanic acid Tetrabutyl ester was dissolved in 18.7g of isopropanol, and then stirred for 30min to obtain the titanium source hydrolysis mixture; and alcohol was removed at 80°C for 1.5h, 50.2g of water and 0.045g of sodium sulfite were stirred for 30min, and the obtained transparent glue was filled Put the solution into the crystallization kettle for crystallization, put the resulting solution into the crystallization kettle, and crystallize at 175°C for 3 days. After washing and drying, the crystallized product is washed with 1M HCl aqueous solution (the liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, and obtained a TS-1 sample with a Si / Ti ratio of 31.2 after XRF testing.

[0046] The Au loading proces...

Embodiment 2

[0048] Repeat Example 1, replace the soluble starch in the defect site auxiliary agent in the preparation process of TS-1 with sodium carboxymethylcellulose, polyacrylamide, polyethyleneimine, the amount of the component substances remains unchanged, after crystallization, After washing and drying, use 1M HCl aqueous solution to wash (the liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, obtained TS-1 samples with Si / Ti ratios of 31.6, 31.9, and 31.8 after XRF testing, and then carried out Au loading to obtain catalyst numbers of 0.38%Au / TS-1-G, 0.38% Au / TS-1-H, 0.38% Au / TS-1-I.

Embodiment 3

[0050] Repeat Example 1, the tetraethyl orthosilicate in the TS-1 preparation process is replaced by tetramethyl orthosilicate, tetrapropyl orthosilicate, the amount of tetrabutyl orthosilicate component material remains unchanged, After crystallization, adopt 1M HCl aqueous solution washing after washing, drying (liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, obtained TS-1 samples with Si / Ti ratios of 31.9, 32.0, and 31.8 after XRF testing, and carried out Au loading to obtain catalyst numbers 0.38%Au / TS-1-J, 0.38% Au / TS-1-K, 0.38% Au / TS-1-L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com