A kind of carbon dioxide hydrogenation synthesis formic acid catalyst and its preparation method and application

A technology of pyridinedicarbonitrile and cyano-p-quinonedimethane, which is applied in the field of carbon dioxide hydrogenation synthesis of formic acid catalyst and its preparation, can solve the problems of low efficiency, achieve good metal dispersion, less operation steps, and stable cycle sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In yet another specific embodiment of the present invention, a method for preparing the above-mentioned Pd-based metal material is provided, the preparation method comprising: immersing a carbon material or a nitrogen-doped carbon material in a Pd-containing precursor solution, stirring under an inert atmosphere , Filtrated, washed and then dried in vacuum at high temperature.

[0038] Wherein, when the Pd-based metal material is a Pd-based bimetallic material, the Pd-containing precursor solution also contains a second metal, and the second metal is any one of Fe, Co, Ni, Cu, and Zn.

[0039] In yet another specific embodiment of the present invention, the precursor of Pd is Pd-containing acids or salts, including but not limited to palladium chloride, potassium chloropalladate, palladium nitrate, palladium acetate, palladium trifluoroacetate, acetylacetone Any one or more of palladium and triphenylphosphine palladium acetate; the second metal precursor is chloride, ni...

Embodiment 1-5

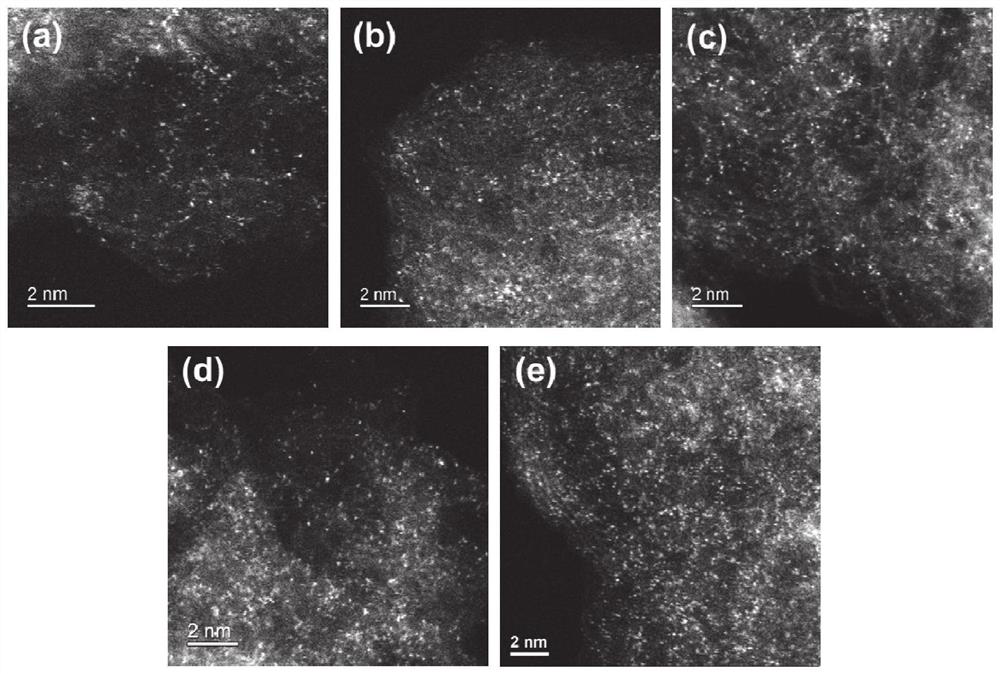

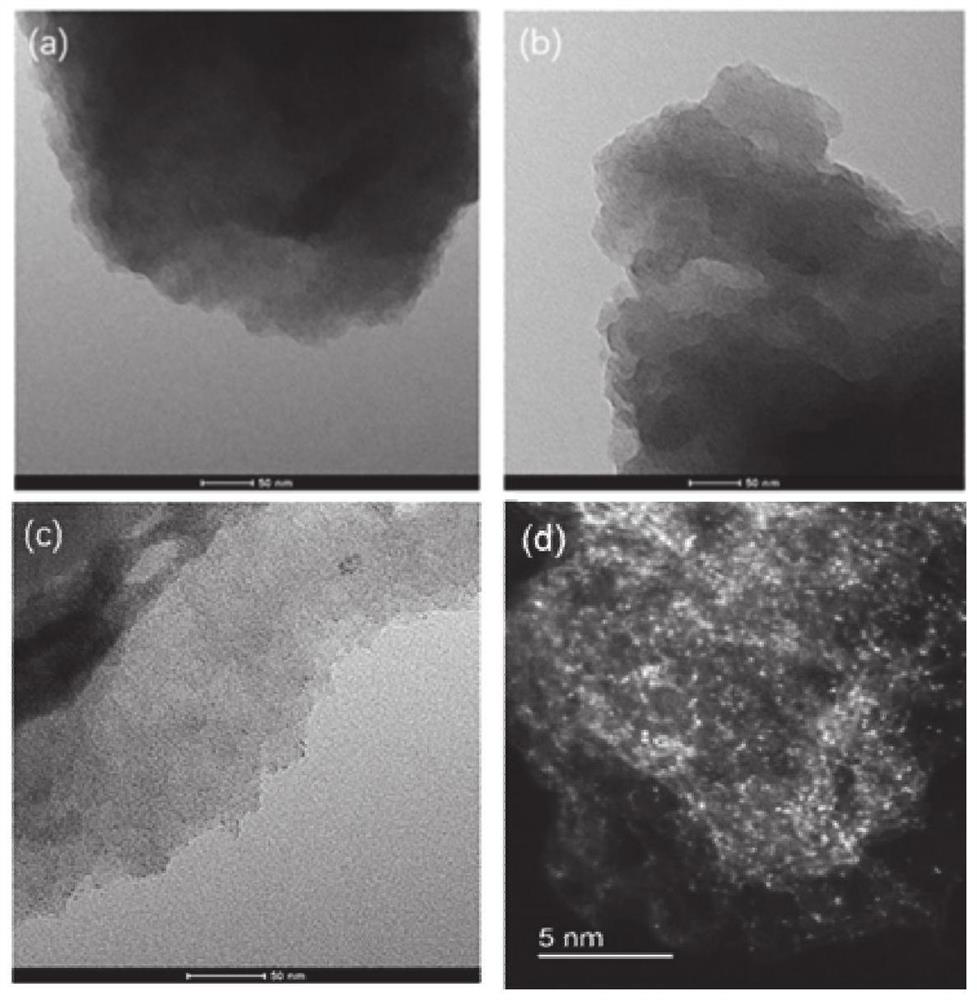

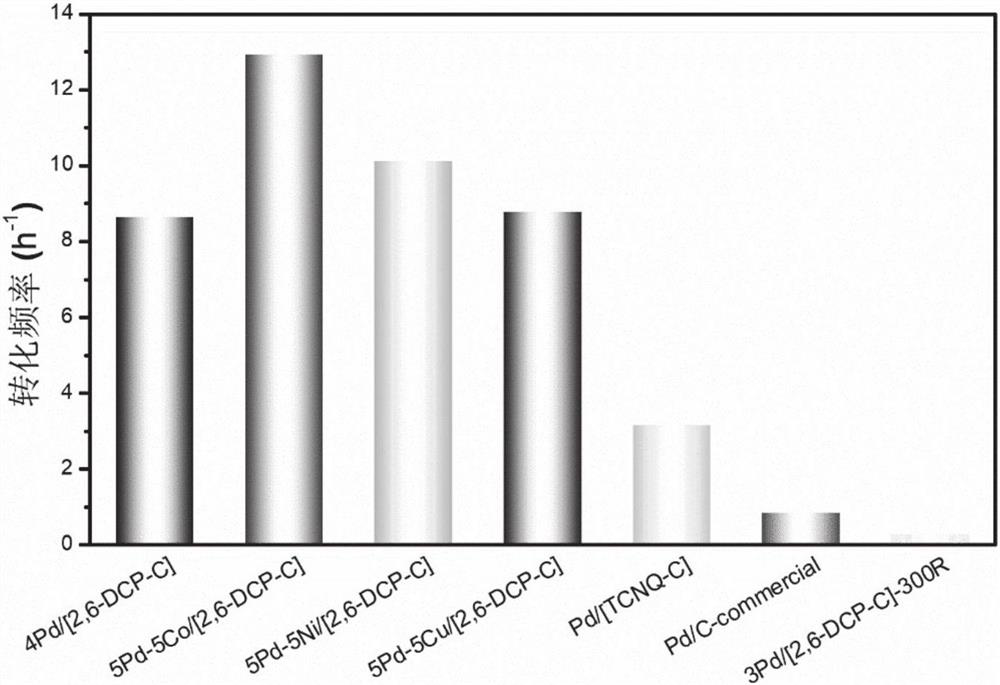

[0052] Examples 1-5 are nitrogen-doped carbon materials loaded with Pd prepared by using the method provided by the present invention and using 2,6-pyridinedicarbonitrile (2,6-DCP) as a precursor. The specific preparation method is as follows: 1. Preparation of nitrogen-doped carbon material: Weigh 3.0 grams of 2,6-pyridinedicarbonitrile and 15.9 grams of ZnCl 2 Solid, grind and mix in a glove box, put it into an ampoule tube for vacuuming and sealing after grinding evenly, then put it in a muffle furnace at 400°C for 20 hours, and then raise the roasting temperature to 600°C for further roasting After 20 hours, after cooling down to room temperature, the roasted sample was ground and added to 1L 2mol / L hydrochloric acid solution, stirred and washed for 12 hours, then filtered, washed with deionized water, washed with tetrahydrofuran, and dried in vacuum at 150°C for 12 hours to obtain nitrogen-doped carbon material sample (2,6-DCP-C). 2. Weigh 1.0 g of the 2,6-DCP-C sample p...

Embodiment 6-8

[0055] Examples 6-8 use the method provided by the present invention to prepare a Pd-based bimetallic catalyst. The specific preparation method is as follows: 1. Preparation of nitrogen-doped carbon material: Weigh 3.0 grams of 2,6-pyridinedicarbonitrile and 15.9 grams of ZnCl 2 Solid, grind and mix in a glove box, put it into an ampoule tube for vacuuming and sealing after grinding evenly, then put it in a muffle furnace at 400°C for 20 hours, and then raise the roasting temperature to 600°C for further roasting After 20 hours, after cooling down to room temperature, the roasted sample was ground and added to 1L 2mol / L hydrochloric acid solution, stirred and washed for 12 hours, then filtered, washed with deionized water, washed with tetrahydrofuran, and dried in vacuum at 150°C for 12 hours to obtain nitrogen-doped carbon material sample (2,6-DCP-C). 2. Weigh 1.0g of the 2,6-DCP-C sample prepared by the above method, and dip it in a certain amount of methanol solution of p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com