Ammonia spraying device and flue gas denitration device

A flue gas and nozzle technology, which is applied in the fields of ammonia spraying devices and flue gas denitrification devices, can solve the problems of high resistance of denitrification ammonia spraying devices, etc., and achieve the effects of increasing mass transfer channels and areas, small wear and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] At present, the power plant is undergoing a new round of ultra-low emission transformation projects, which involves the transformation and replacement of a large number of flue gas denitrification devices. The modified or newly built denitrification reactor will install many ammonia injection devices in the vertical section of the reactor for the injection of ammonia gas. The ammonia gas reacts with the nitrogen oxides in the flue gas in the reactor, and the nitrogen oxides remove. The existing ammonia injection device is made of circular steel pipes, holes are opened on the circular pipes, and nozzles of different angles are cross-welded to realize the injection coverage of ammonia gas. Ammonia injection pipes are arranged side by side and parallel inside the flue. The projected area of the pipes occupies almost half of the cross-sectional area of the entire flue. The effective cross-section that the flue gas can pass through is reduced, which greatly increases the...

Embodiment 2

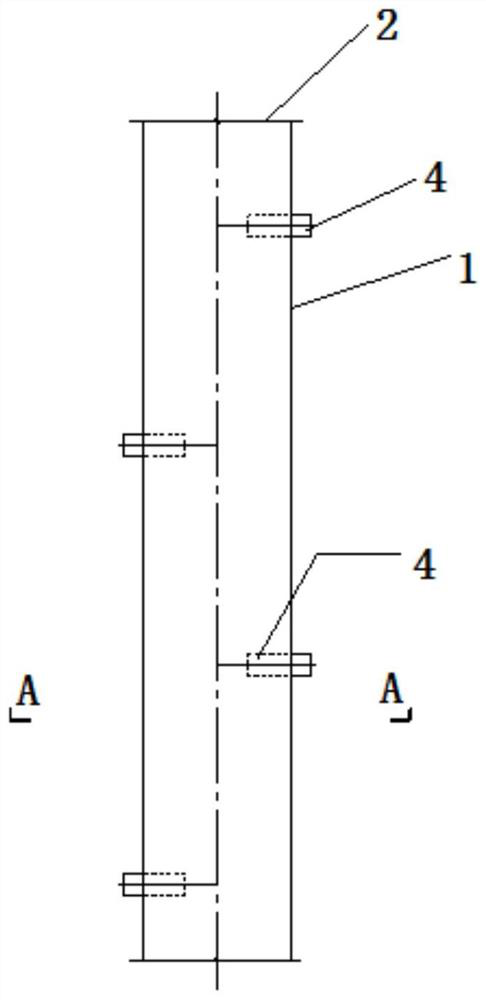

[0043] This embodiment provides a flue gas denitrification device, comprising the ammonia injection device and the flue provided in the above embodiments, and the ammonia injection pipe 1 of the ammonia injection device is horizontally arranged in the flue. Since the minor axis 2 of the cross-section of the ammonia injection pipeline 1 is perpendicular to the flow direction of the flue gas in the flue, and the major axis 3 is parallel to the flow direction of the flue gas in the flue, the elliptical cross-sectional area of the ammonia injection pipeline 1 is comparable to that of the prior art Under the premise that the circular cross-sectional area is equal, that is, under the condition that the flow rate of ammonia injection remains unchanged, since the minor axis 2 is perpendicular to the flow direction of flue gas, under the premise that the length of ammonia injection pipeline 1 remains unchanged, ammonia injection pipeline 1 The projected area can be greatly reduced, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com