Preparation method and application of positive electrode material lithium iron phosphate

A technology of lithium iron phosphate and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problem of high raw material price, and achieve the effect of reducing preparation cost, long cycle life and high capacity density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

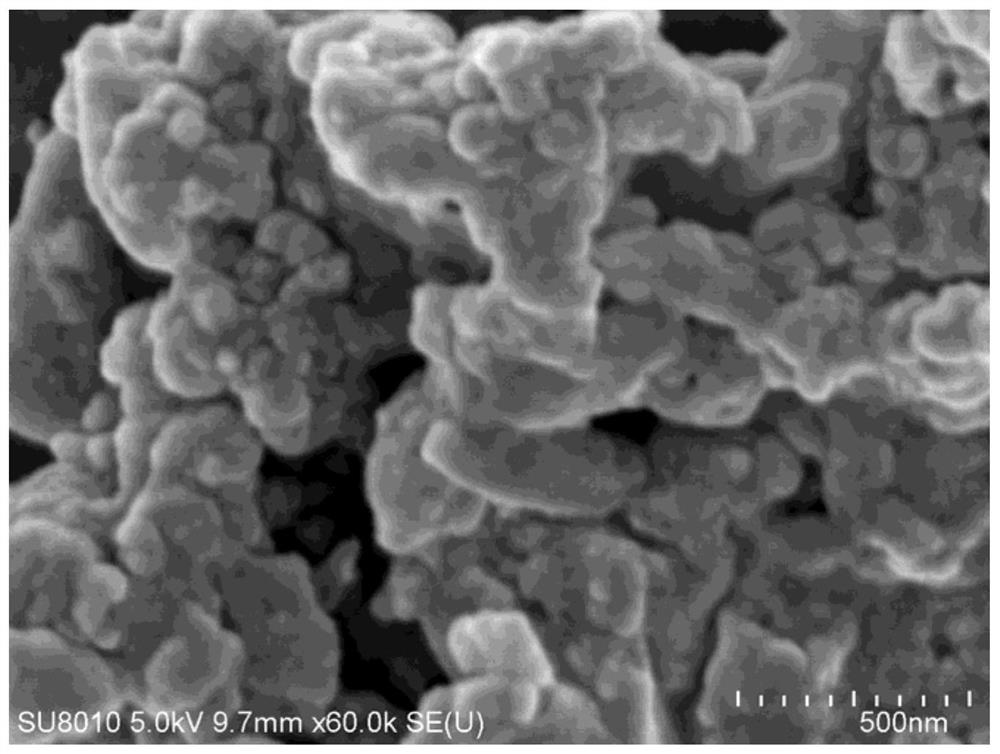

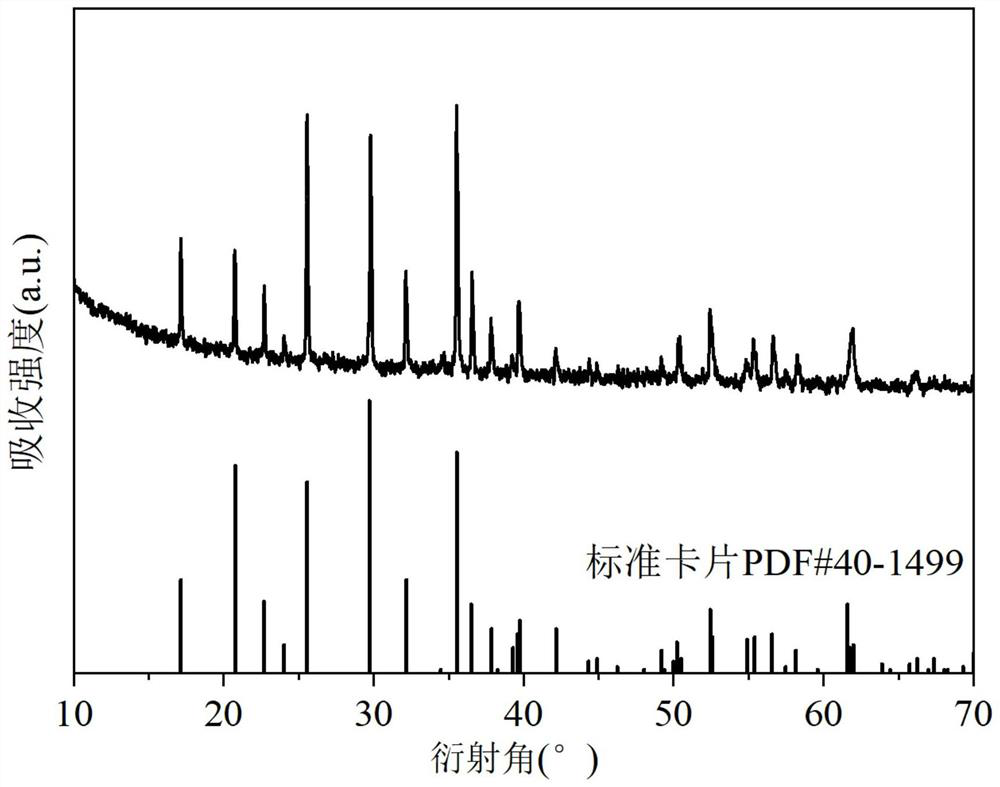

Image

Examples

Embodiment 1

[0045] The phosphoric acid aqueous solution that adopts in this embodiment is that mass concentration is 50%, and lithium source, iron source adopt lithium carbonate and iron oxide that the following method makes respectively;

[0046] The preparation method of lithium carbonate is as follows: it is obtained by using the "one-step acid dissolution method" of fly ash to produce alumina, which is obtained from the remaining evaporated scale mother liquor in the evaporation and crystallization process, specifically:

[0047] Step1. Calcining the above-mentioned evaporated scale mother liquor at 500°C to obtain a calcined product;

[0048] Step2. Leach the calcined product in the secondary evaporation condensed water in the "one-step acid dissolution method" fly ash preparation alumina process, and then filter to obtain lithium-containing solution a; wherein, the mass ratio of the calcined product to the leachate is 1:1;

[0049] Step3. Mix the lithium-containing solution a with ...

Embodiment 2

[0065] The difference between this embodiment and Example 1 is that the composition of the steamed scale mother liquor used in the lithium carbonate preparation process and the iron element enrichment solution used in the iron oxide preparation process is different, as follows:

[0066] In the step of preparing lithium carbonate, the content of lithium ion in solution f is 4598mg / L, the content of calcium ion is 11mg / L, the content of magnesium ion is 57mg / L, the content of sodium ion is 25mg / L, the content of potassium ion The content is 0.8mg / L, and the content of aluminum ion is 0.6mg / L;

[0067] The content of iron ions in the iron enrichment solution is 198767mg / L, the content of sodium ions is 4.7mg / L, the content of aluminum ions is 1.9mg / L, the content of titanium ions is 0.85mg / L, and the content of silicon ions is 79mg / L.

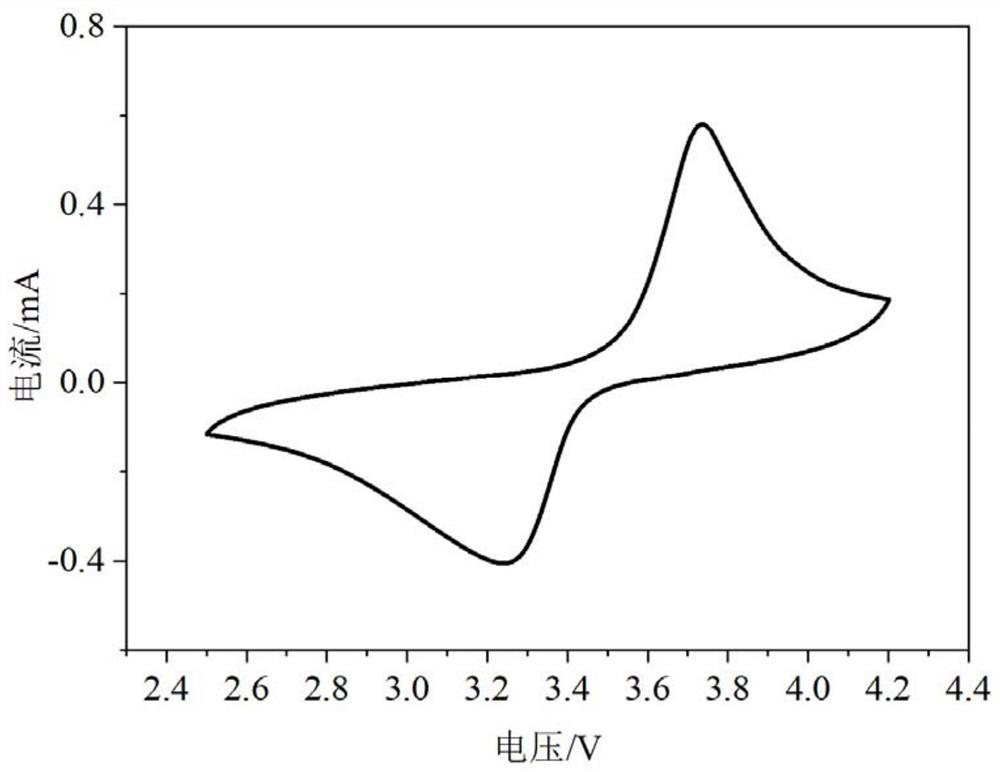

[0068] The lithium iron phosphate prepared in this example is assembled with lithium metal to test the 2025 battery, and the charge and dischar...

Embodiment 3

[0070] The difference between this embodiment and Example 1 is that the composition of the steamed scale mother liquor used in the lithium carbonate preparation process and the iron element enrichment solution used in the iron oxide preparation process is different, as follows:

[0071] In the step of preparing lithium carbonate, the content of lithium ion in the solution f is 1323mg / L, the content of calcium ion is 34mg / L, the content of magnesium ion is 23mg / L, the content of sodium ion is 24mg / L, the content of potassium ion The content is 0.5mg / L, and the content of aluminum ion is 0.2mg / L;

[0072] The content of iron ions in the iron enrichment solution is 100672mg / L, the content of sodium ions is 0.7mg / L, the content of aluminum ions is 0.7mg / L, the content of titanium ions is 0.01mg / L, and the content of silicon ions is 13mg / L.

[0073] The lithium iron phosphate prepared in this example is assembled with lithium metal to test the 2025 battery, and the charge and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com