Preparation method of surfacing coating on sealing surface of valve

A technology of valve sealing and surface stacking, which is applied in the coating, metal material coating process, etc., can solve the problems of small deformation, low mechanical bonding strength, thermal deformation and cracks, etc., and achieve the suppression of coating cracks and wear resistance The effect of improving and increasing the hardness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

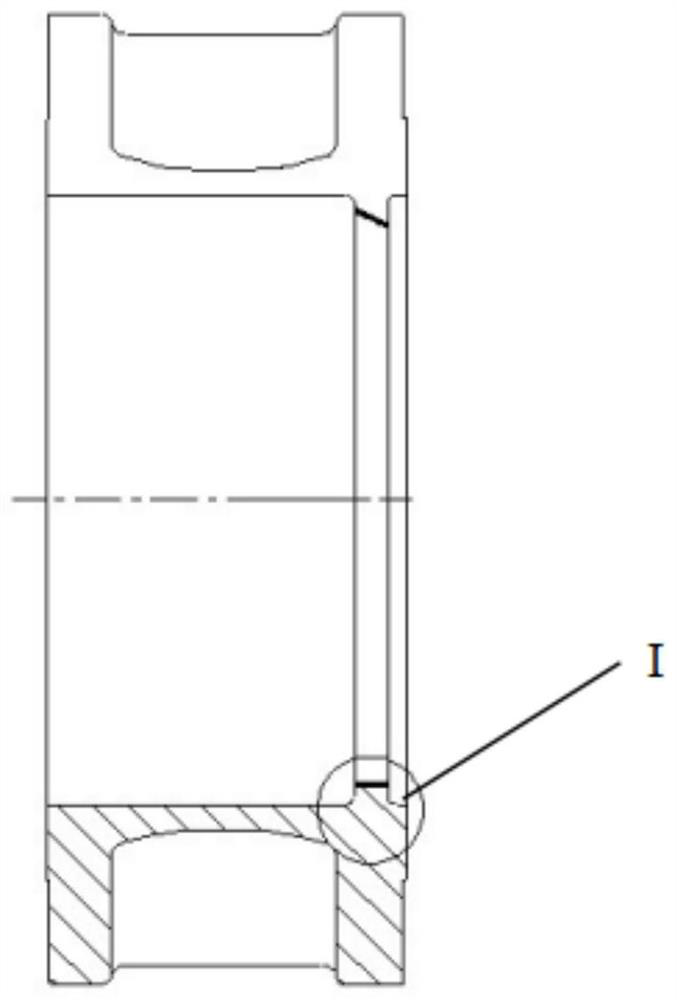

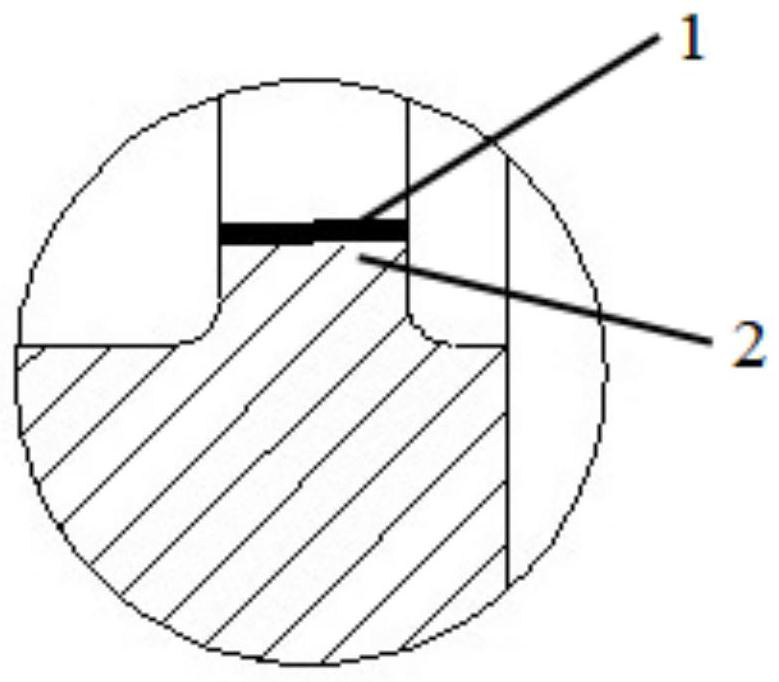

[0034] A kind of preparation method of overlay welding coating on valve sealing surface, such as Figure 1-4 As shown, the sealing surface includes one or more sealing areas in the valve that are in direct contact with the medium, such as the ball and seat of the ball valve, the seat and the sealing ring of the butterfly valve, the gate plate and the seat of the gate valve, etc.

[0035] Including the following steps:

[0036] (1) Obtain cladding powder:

[0037] First mix the metal binder phase and the ceramic reinforcement phase according to the ratio, and then add 0.4~0.6% CeO 2 As a grain inhibitor, the cladding powder is obtained after fully mixing by mechanical means; the composite powder is weighed in proportion and mixed in a mixer for 2-4 hours, and the grinding balls use tungsten carbide balls. 1:8~10.

[0038] (2) Heating valve sealing surface:

[0039] The sealing surface of the valve needs to be heated to 150~200°C as a whole before cladding;

[0040] (3) Ins...

Embodiment 1

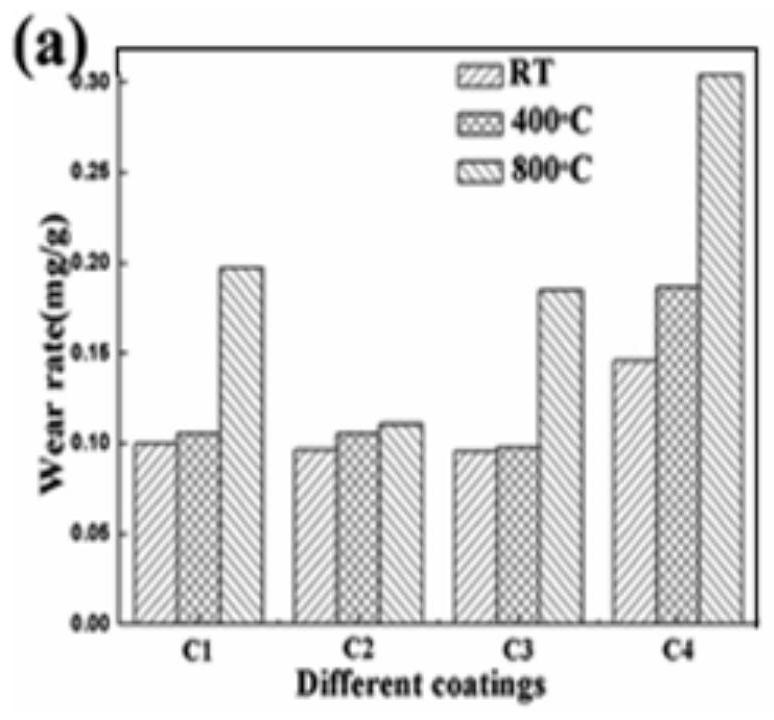

[0051] Example 1: Laser cladding is used to clad a composite hardened coating on the sealing surface of a 12-inch triple eccentric butterfly valve seat, the composition of which is 69.5% nickel-based alloy (grain size 45-75 μm): 30% 12Co-WC (grain size 24-45 μm )-0.5%CeO 2 (particle size 24-45μm), hardness 700~750HV 10 .

[0052] First, weigh the three powders in proportion and mix them in the mixer for 2-4 hours. The grinding balls are tungsten carbide balls, and the ratio of material to ball is 1:8~10. After the mixed powder is sieved, it is dried in a vacuum drying oven at a drying temperature of 150-200°C, and the powder accumulation thickness during the drying process is ≤5mm. The material of the valve body is CF8, and it needs to be preheated at 200°C for 1.5h as a whole. Laser cladding equipment with fiber laser and coaxial powder feeding cladding head are used for cladding operation. The cladding power is 2000W, the scanning speed is 250mm / min, the spot diameter is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com