New energy battery box containing water-based stone-impact-resistant coating

An anti-stone attack and new energy technology, applied in coatings, fire-resistant coatings, battery pack components, etc., can solve problems such as easy to be struck by stones, short service life, delamination, etc., to prevent damage to the coating and reduce vibration. Effects of waves and sound waves, noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the present embodiment, the preparation method of each part of the acrylate rubber emulsion comprises the steps:

[0037] (A1), 30-50 parts by weight of acrylate monomer and 0.15-2.5 parts by weight of allyl methacrylate are uniformly mixed, and 30-50 parts by weight of sodium dodecylbenzenesulfonate with a concentration of 0.1-2wt% are added In the solution, acrylate mixed liquid is obtained after dispersion; 0.03-0.5 parts by weight of initiator, 0.03-1 parts by weight of sodium dodecylbenzenesulfonate and 30-50 parts by weight of water are uniformly mixed to obtain a diluted aqueous solution;

[0038] (A2), under the conditions of continuously stirring and keeping the temperature at 70-85°C, add the acrylate mixed solution into the diluted aqueous solution, and react for 2-3 hours to obtain the acrylate rubber emulsion;

[0039] Wherein, the acrylate monomer is at least one of methyl acrylate, ethyl acrylate and n-propyl acrylate; the initiator is benzoyl peroxide...

Embodiment 1

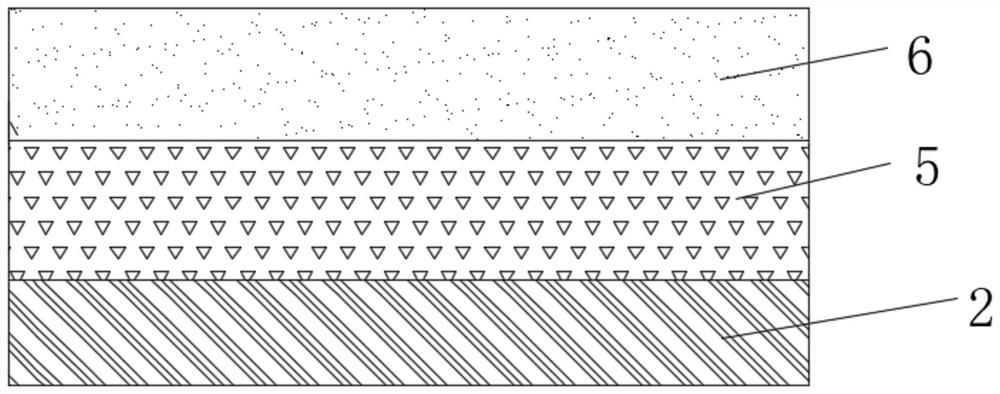

[0044] Such as Figure 1-3 As shown, a new energy battery case containing a water-based anti-stone chip coating includes an upper case 1 and a lower case 2 connected to the upper case 1, and the inner wall of the upper case 1 is sequentially compounded with first The anti-stone-damping water-based damping coating 3 and the first normal-temperature high-performance water-based damping coating 4, the inner wall of the lower box 2 is sequentially compounded with the second anti-stone-damping water-based damping coating 5 and the second normal-temperature high-performance water-based damping coating Layer 6.

[0045] The thicknesses of the first stone-damping water-resistant damping coating 3 and the second rock-hammering water-resistant damping coating 5 are both 1.3-2.0 mm.

[0046] Both the first anti-stone-damping water-based damping coating 3 and the second anti-stone-hammering water-based damping coating 5 are formed by coating and drying the water-based PVC paint doped wit...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is:

[0052] The water-based PVC paint doped with calcium carbonate includes the following raw materials in parts by weight: 60 parts of water-based PVC resin blended emulsion, 0.5 part of defoamer, 0.5 part of dispersant, 45 parts of modified calcium carbonate filler, 0.5 part of thickener 8 parts and 8 parts water. The preparation method of the water-based PVC paint doped with calcium carbonate is to sequentially add water, water-based PVC resin blend emulsion, dispersant, modified calcium carbonate filler, defoamer and thickener under stirring condition and mix uniformly.

[0053] The water-based PVC resin blend emulsion is formed by mixing E-2302 water-based PVC emulsion and self-drying water-based PVC resin SGR-2235W in a weight ratio of 4:1; the preparation method of each part of the modified calcium carbonate filler is by weight Add 20 parts of titanate coupling agent TMC-201 and 40 parts of calcium carbona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com